Method for comprehensively recycling leaching slag in production of electrolytic manganese metal and manganese dioxide

A technology of electrolytic manganese metal and manganese dioxide, applied in application, fertilizer mixture, ammonium sulfate, etc., can solve problems such as difficulty in iron removal and excessive filter residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

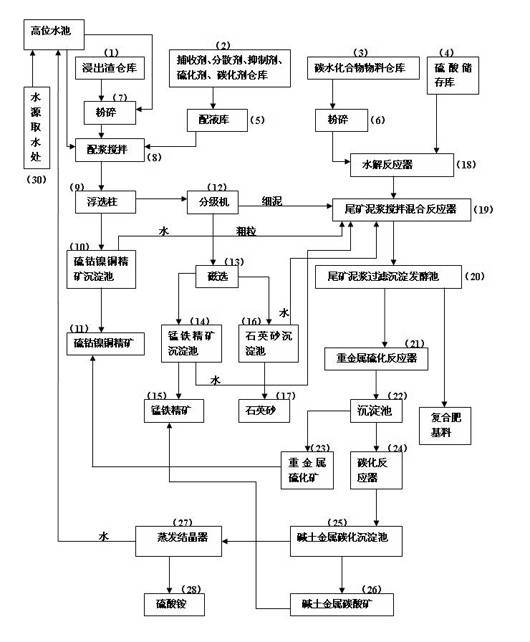

Method used

Image

Examples

Embodiment Construction

[0062] Below with in conjunction with embodiment for further detailed description:

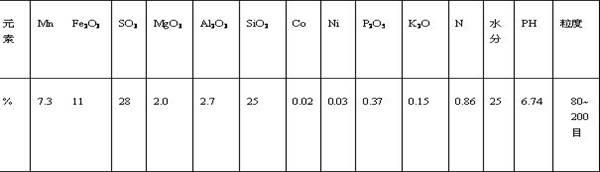

[0063] 1. Take 1000 kg of leaching slag from the process of producing electrolytic manganese metal by Sanmanganlong Manganese Industry Co., Ltd., Daxin County, Guangxi.

[0064] 2. The ingredients contained in the slag are shown in the table:

[0065]

[0066] 3. First make the following auxiliary materials into a solution or a mixed solution, and then follow the steps below:

[0067] (1) Weigh 150g potassium hexametaphosphate and dissolve it in 1000g water to make a solution.

[0068] (2) Dissolve 150g of potassium silicate or water glass in 1000g of water to make a solution.

[0069] (3) Weigh 170g butyl xanthate and dissolve it in 1000g water to make a solution.

[0070] (4) Weigh 170g of butyl ammonium black medicine and dissolve it in 1000g of water to make a solution.

[0071] (5) Weigh 200g of ammonium sulfide and dissolve it in 1000g of water to make a solution.

[0072...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com