Equipment and method for slowing down salt-sodium sulfate co-production sodium sulfate flash tank scaling

A salt-nitrate co-production and nitrification flash technology, applied in chemical instruments and methods, alkali metal sulfite/sulfite, alkali metal chloride, etc., can solve the problem of affecting production and steam consumption, reducing the composition of the nitric system and other problems, to achieve the effect of simple structure, slow down the generation of salt scale, and prolong the operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

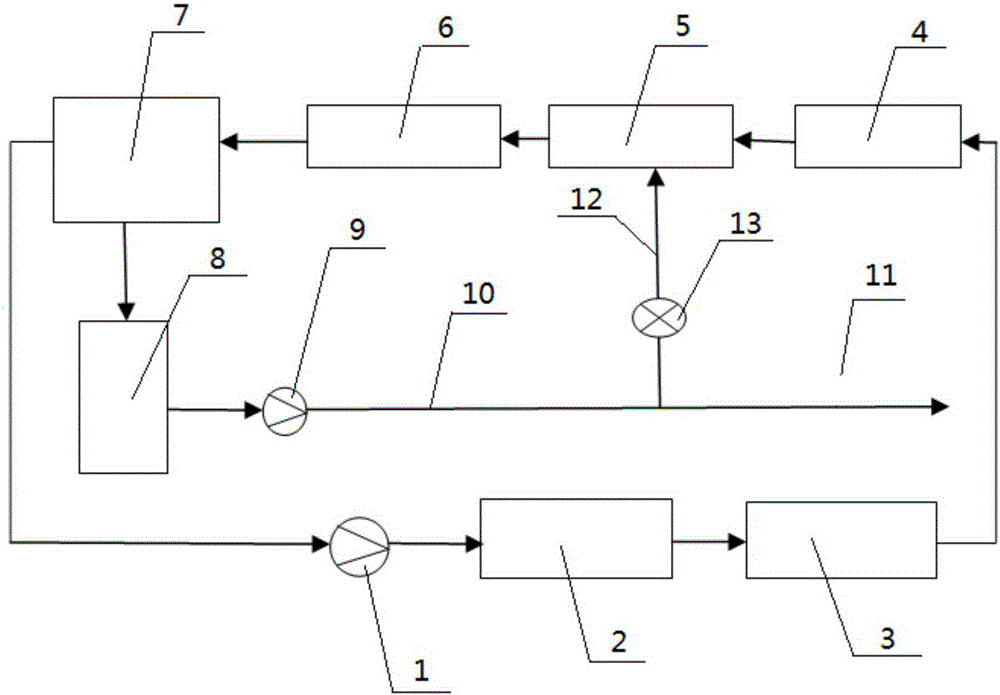

[0012] Such as figure 1 As shown, the co-production of salt and nitrate is based on the fact that the solubility of NaCl in water increases with the increase of temperature, and Na 2 SO 4 The principle that the solubility in water decreases with the increase of temperature, and the separation of NaCl (ie salt) and Na in the raw brine 2 SO 4 (ie nitrate). The specific loop part is as figure 1 As shown, the feed liquid is heated through the primary preheater 2 and the secondary preheater 3 through the circulation pump 1, so that the Na in the feed liquid 2 SO 4 The solubility becomes smaller and the solubility of NaCl increases. Then the feed liquid enters the nitric acid evaporation tank 4 to evaporate moisture, so that Na 2 SO 4 precipitation, the concentration of NaCl increases. Then the feed liquid with higher NaCl concentration is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com