Environment-friendly conductive silver paste and preparation method thereof and crystalline silicon solar cell prepared from environment-friendly conductive silver paste

A conductive silver paste, an environmentally friendly technology, applied in the field of solar cells to achieve high conversion efficiency, surface tension improvement, and lower resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

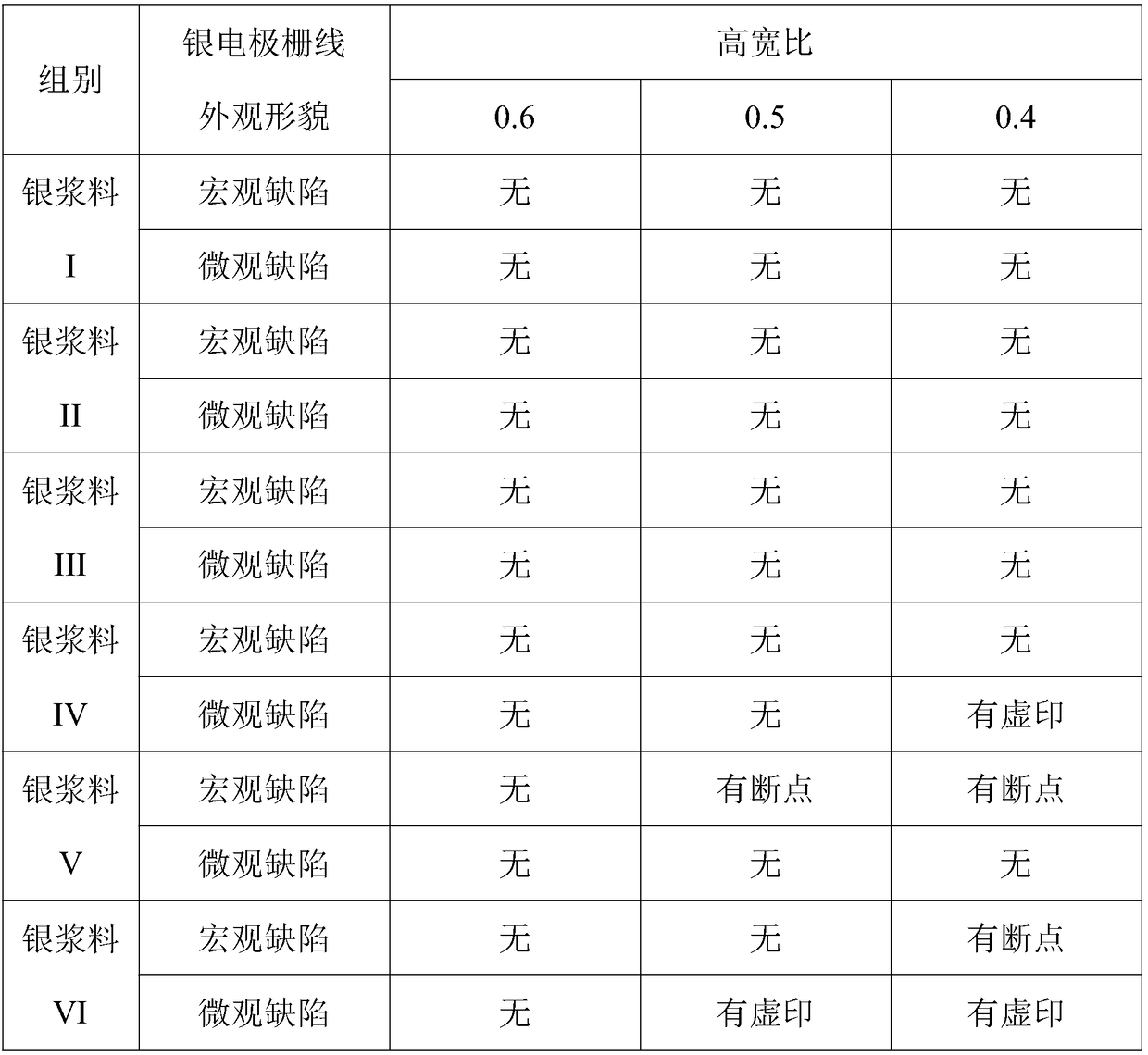

Examples

Embodiment 1

[0022] The preparation of embodiment 1 environmental protection conductive silver paste I

[0023] Step 1. Preparation of compound silver powder: Add ammonia water dropwise to a silver nitrate solution with a mass concentration of 0.5mol / L, the molar ratio of ammonia water to silver nitrate is 1:1, mix evenly to obtain a mixed solution A, and the mass ratio is Mix 1:1 oleic acid and ascorbic acid solution with a mass concentration of 1.5mol / L to obtain mixed solution B, then add solution A and solution B dropwise into the reactor at the same time, the mass ratio of solution A to solution B is 18: 1. The reaction temperature is 15-45°C, and the reaction time is 2-5h. After the reaction is completed, filter the reactant to obtain the filter residue, wash the filter residue with deionized water and absolute ethanol in turn, and dry the washed product under vacuum at 50°C for 4h Obtain the micron silver powder, the particle diameter of the micron silver powder is 0.8 μm, and the t...

Embodiment 2

[0028] The preparation of embodiment 2 environmental protection conductive silver paste II

[0029]Step 1. Preparation of compound silver powder: Add ammonia water dropwise to a silver nitrate solution with a mass concentration of 0.5 mol / L, the molar ratio of ammonia water to silver nitrate is 4:1, mix evenly to obtain a mixed solution A, and the mass ratio is 1: 1.2 oleic acid and ascorbic acid solution with a mass concentration of 1.5mol / L are mixed evenly to obtain a mixed solution B, and then solution A and solution B are added dropwise to the reactor at the same time, and the mass ratio of solution A to solution B is 40: 1. The reaction temperature is 15-45°C, and the reaction time is 2-5h. After the reaction is completed, filter the reactant to obtain the filter residue, wash the filter residue with deionized water and absolute ethanol in turn, and dry the washed product under vacuum at 50°C for 4h Obtain the micron silver powder, the particle diameter of the micron sil...

Embodiment 3

[0034] The preparation of embodiment 3 environmental protection conductive silver paste III

[0035] Step 1. Preparation of compound silver powder: Add ammonia water dropwise to a silver nitrate solution with a mass concentration of 0.5mol / L, the molar ratio of ammonia water to silver nitrate is 3:1, mix evenly to obtain a mixed solution A, and the mass ratio is 1: 1.1 oleic acid and ascorbic acid solution with a mass concentration of 1.5mol / L are mixed evenly to obtain mixed solution B, and then solution A and solution B are added dropwise to the reactor at the same time, the mass ratio of solution A to solution B is 25: 1. The reaction temperature is 15-45°C, and the reaction time is 2-5h. After the reaction is completed, filter the reactant to obtain the filter residue, wash the filter residue with deionized water and absolute ethanol in turn, and dry the washed product under vacuum at 50°C for 4h Obtain the micron silver powder, the particle diameter of the micron silver p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com