Recovery method of polyphenylene sulfide byproduct salt

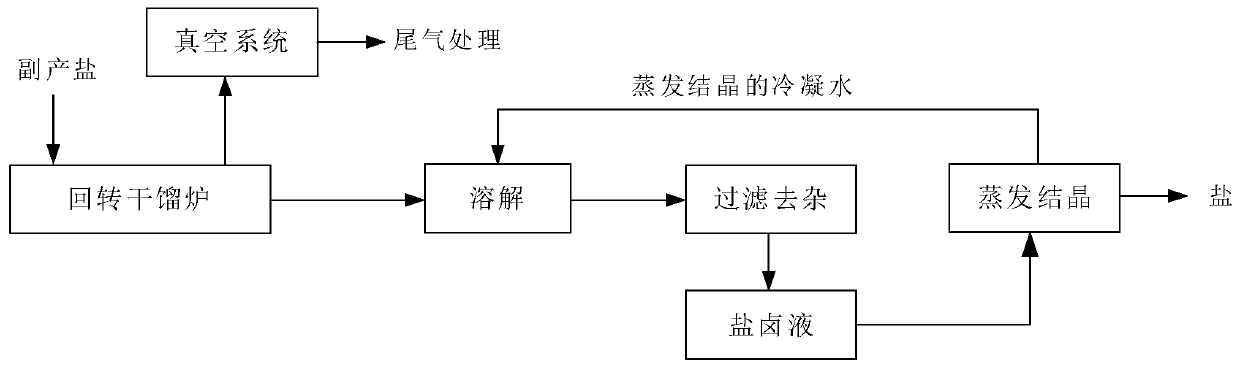

The technology of a polyphenylene sulfide and a recovery method is applied in the recovery and treatment of by-product salt sodium chloride, and the recovery field of polyphenylene sulfide by-product salt, which can solve the problem that the purity of sodium chloride needs to be further improved, the equipment requirements are high, and the calcination The problem of high temperature, to achieve the effect of reducing unfriendly emissions, low equipment requirements, and easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

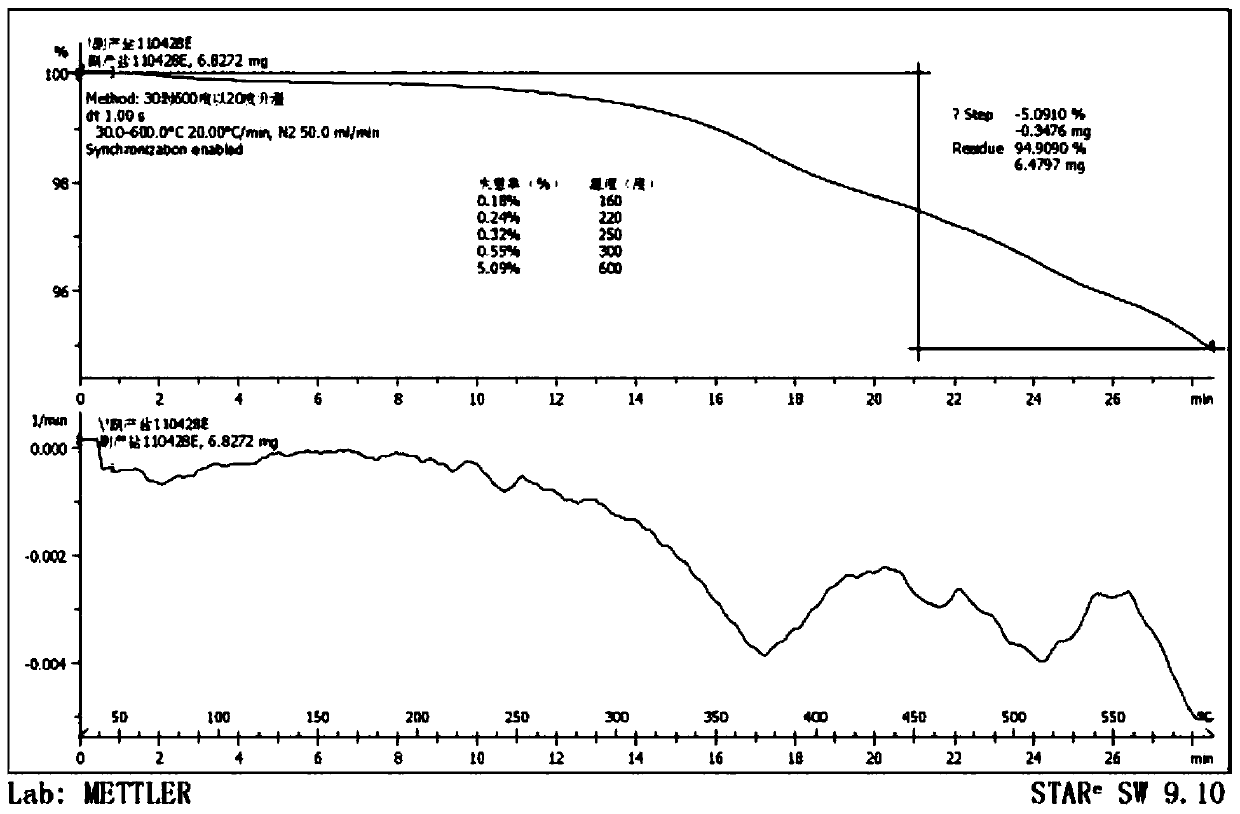

[0049] Add 100 kg of the above-mentioned by-product salt into an electrically heated rotary retort furnace and heat up to 350° C., and maintain it for 3 hours under a vacuum of -0.097 MPa, release and cool to obtain 96 kg of sodium chloride containing black impurities. Take 100g from it and put it into 300ml water to dissolve, then filter through a microporous filter to obtain a colorless filtrate, i.e. brine, through the detection of SS, ammonia nitrogen and COD of this colorless filtrate, it is 9mg / l respectively , 2mg / l, 3mg / l, through this solution is carried out evaporative crystallization completely, the sodium chloride crystal that obtains 95.041g is colorless, and sodium chloride content is 99.83%, see Table 1 for details.

Embodiment 2

[0051] Add 100 kg of the above-mentioned by-product salt into an electric heating rotary retort furnace and heat up to 450° C., vacuum degree -0.097 MPa, maintain for 1.5 hours, release and cool to obtain 96.3 kg of sodium chloride with black impurities. Take 100g from it and put it into 300ml water to dissolve, then filter through a microporous filter to obtain a colorless filtrate, i.e. brine, through the detection of SS, ammonia nitrogen and COD of this colorless filtrate, it is 2mg / l respectively , 1mg / l, 7mg / l, through this solution is carried out evaporative crystallization completely, the sodium chloride crystal that obtains 95.043g is colorless, and sodium chloride content is 99.85%, see Table 1 for details.

Embodiment 3

[0053] Add 100 kg of the above-mentioned by-product salt into the electric heating rotary retort furnace and heat up to 500° C., under the condition of vacuum degree -0.095 MPa, keep it for 1.5 hours, release and cool to obtain 95.9 kg of sodium chloride with black impurities. Take 100g from it and put it into 300ml water to dissolve, then filter through a microporous filter to obtain a colorless filtrate, i.e. brine, through the detection of SS, ammonia nitrogen and COD of this colorless filtrate, it is 8mg / l respectively , 2mg / l, 5mg / l, through this solution is carried out evaporative crystallization completely, the sodium chloride crystal that obtains 95.042g is colorless sodium chloride content 99.83%, see table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com