Method synthesizing nanocrystalline by assistance of soluble salt

A soluble, nanocrystalline technology that can be used in nanotechnology, nanotechnology, nanostructure fabrication, etc., to solve problems such as limiting large-scale production and GaN loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

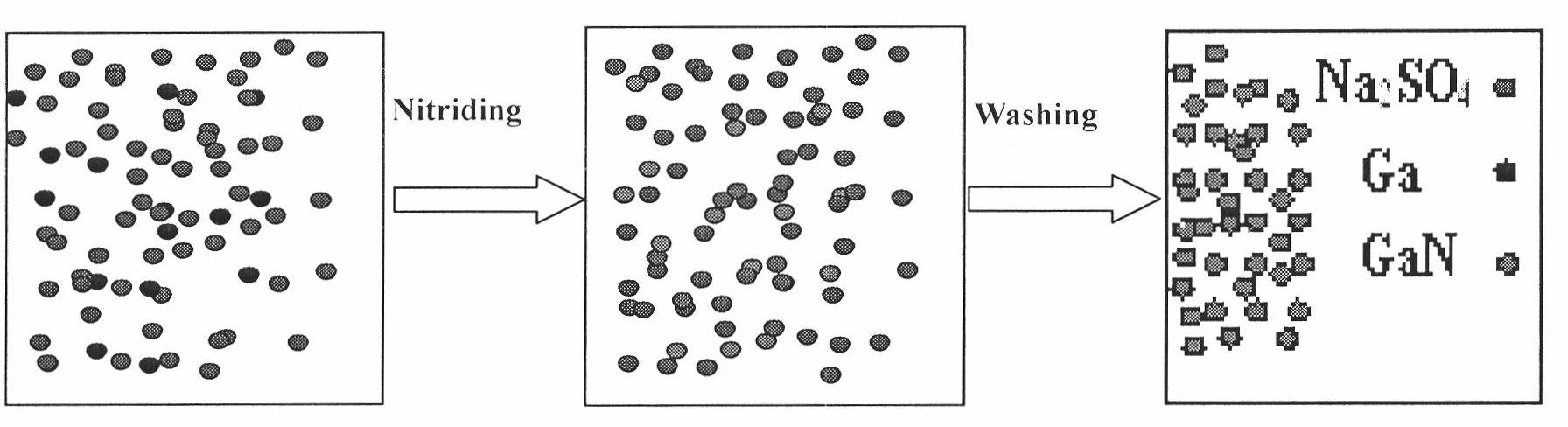

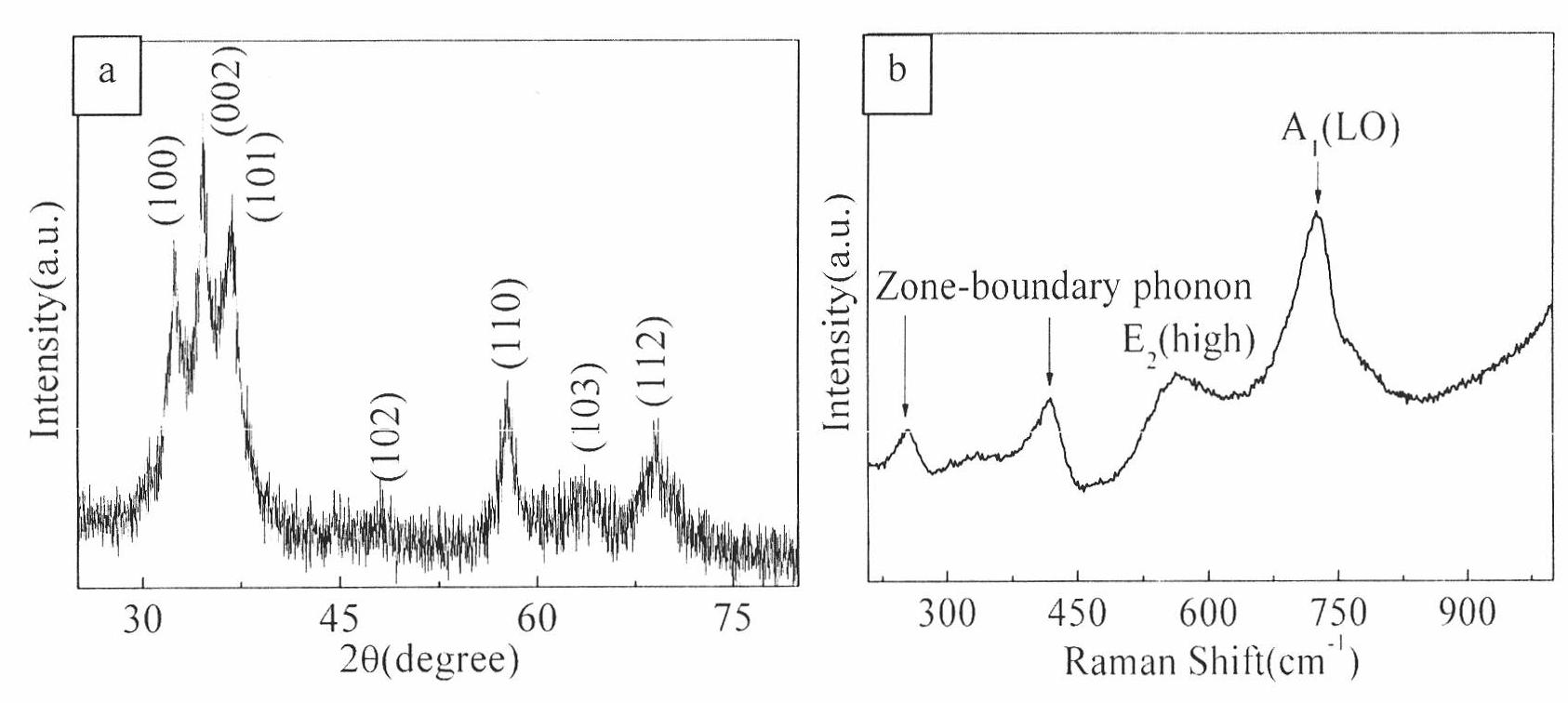

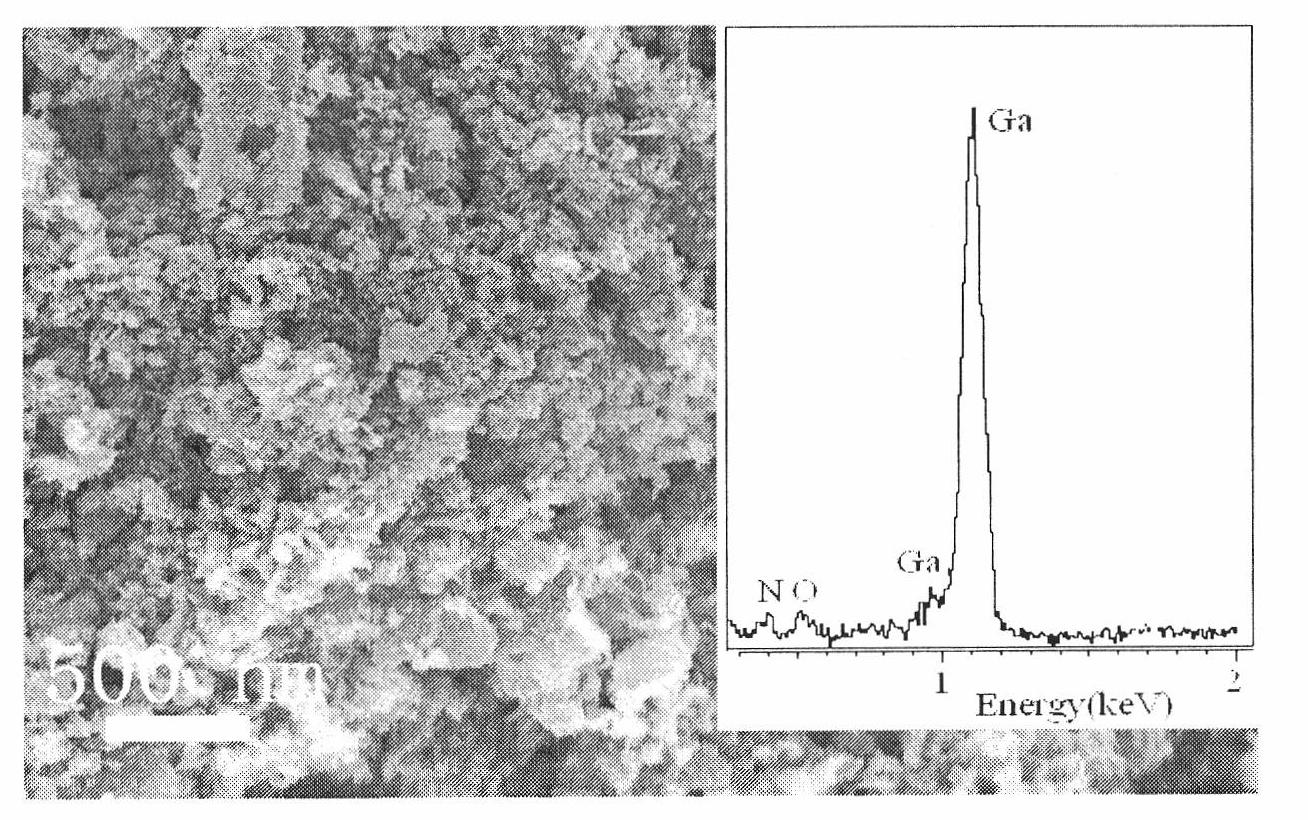

[0013] Thoroughly grind 1 gram of metal Ga and 10 grams of sodium sulfate at 35°C, then nitride the mixture of metal Ga and sodium sulfate with ammonia gas at 700°C for 3 hours, then rinse the nitriding mixture repeatedly with distilled water to wash off the sodium sulfate and finally obtain Pure GaN nanocrystalline powder.

Embodiment 2

[0015] At 35 °C, metal Al and Na were fully ground at a ratio of 1:15, respectively. 2 SO 4 The mixture was then nitrided with ammonia gas for 3.5 hours at a temperature of 750° C., and then the oxidized mixture was repeatedly washed with distilled water to wash off sodium sulfate and finally obtain pure AlN nanocrystalline powder.

Embodiment 3

[0017] At 35 °C, metal In and Na were fully ground at a ratio of 1:20, respectively. 2 SO 4 The mixture was then nitrogenized with ammonia gas at a temperature of 650° C. for 2.5 hours, and then the oxidized mixture was repeatedly washed with distilled water to wash off sodium sulfate to finally obtain pure InN nanocrystalline powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com