Preparation method for supercapacitor material MoO2/graphene/g-C3N4

A technology of supercapacitors and graphene, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, nanotechnology for materials and surface science, etc., can solve the problem of insufficient performance of supercapacitor electrodes and the cost of precursor carbon materials High, unstable structure and other issues, to achieve the effect of improving cycle charge and discharge stability, good cycle stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

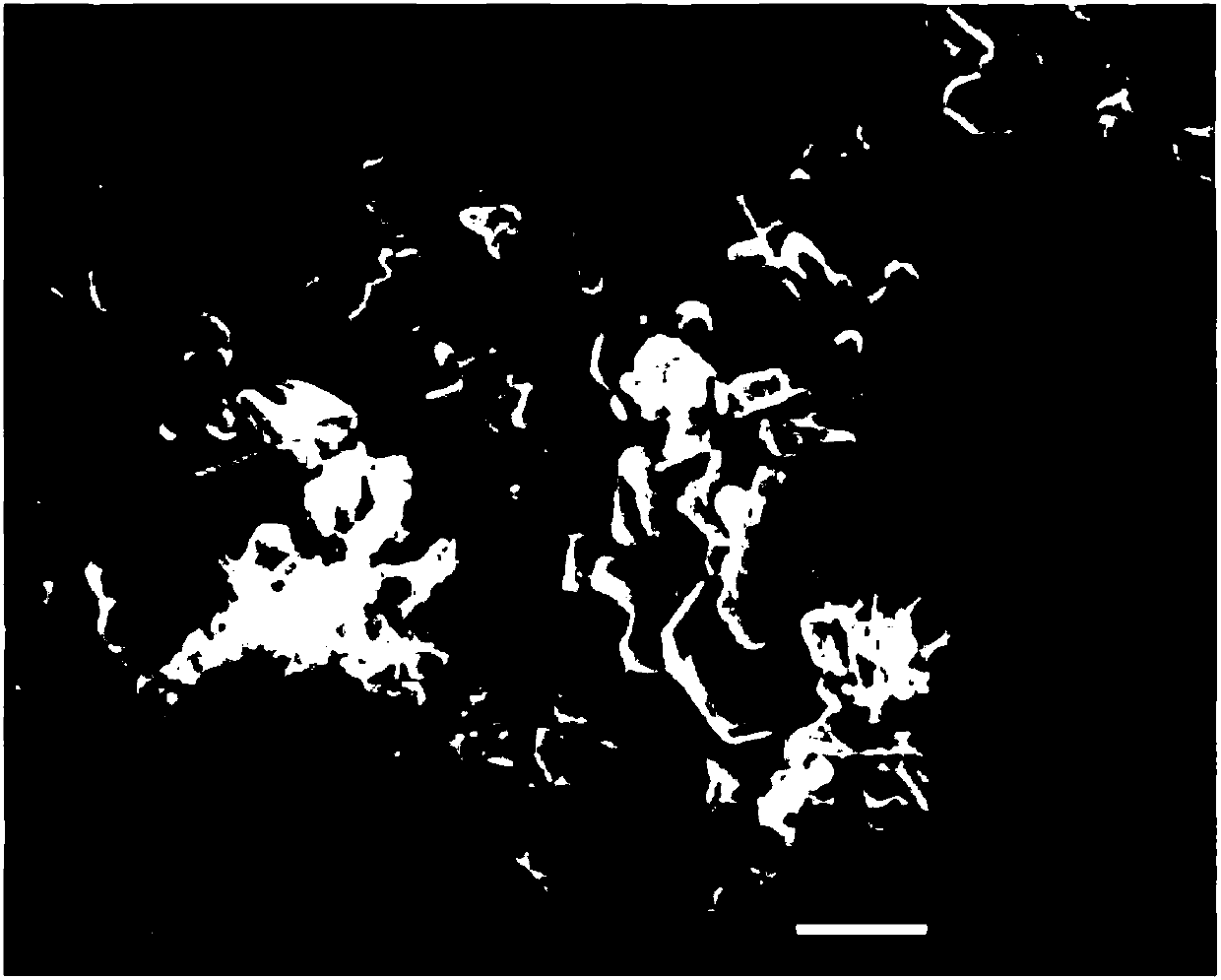

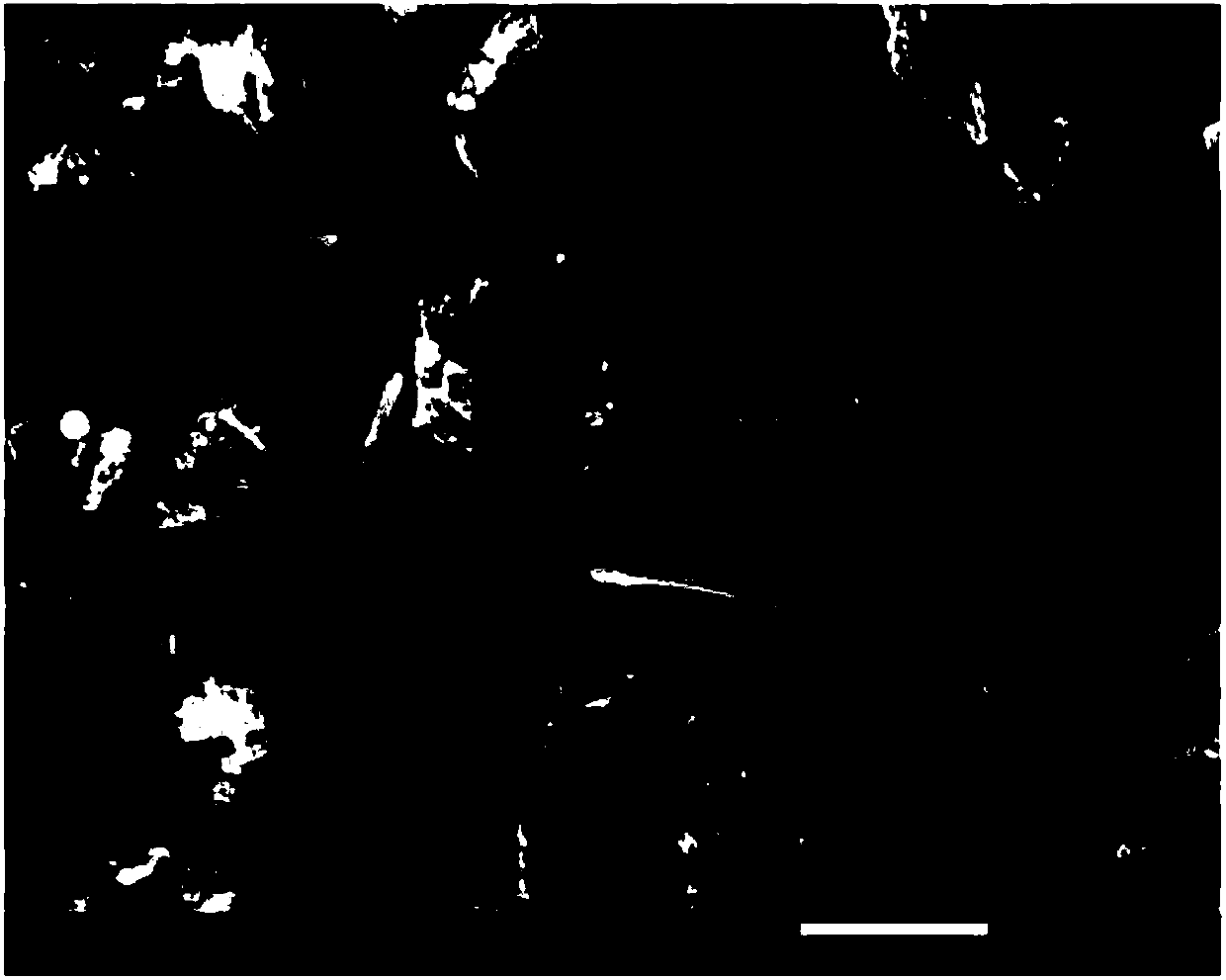

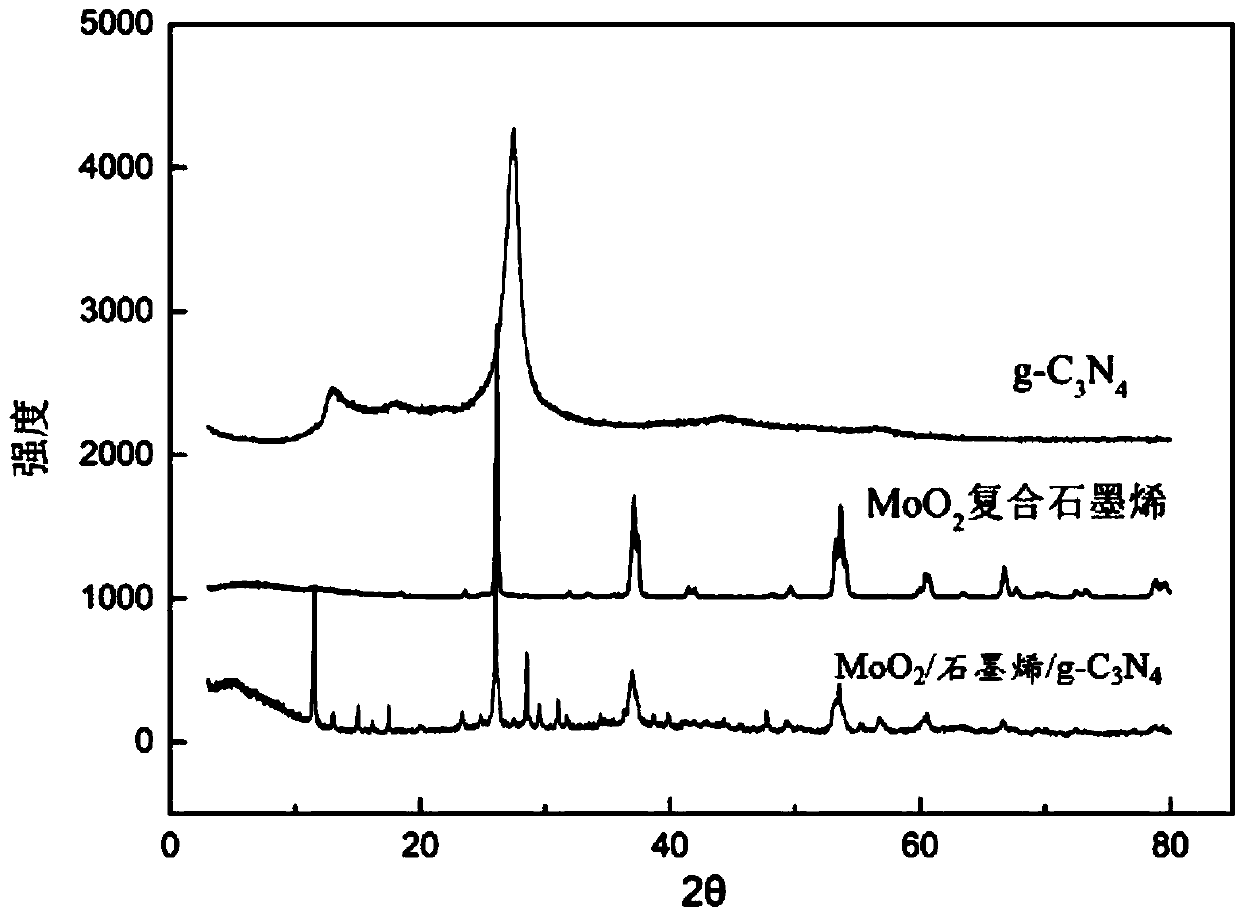

[0032] 14 mg of graphene oxide microchips were dispersed in 14 ml of deionized water for 30 min using a cell pulverizer to obtain a 1 mg / ml graphene oxide dispersion. Dissolve 0.84g of sodium molybdate dihydrate and 2.1g of sodium salicylate in 28ml of deionized water, stir magnetically for 10 minutes to fully dissolve it, and mix it with the graphene oxide dispersion to obtain a mixed solution. Mo in solution 2+ The molar ratio to the capping agent is 1:4, and the concentration of the capping agent in the mixed solution is 0.3mol / L. Then use hydrochloric acid to adjust the pH to 1.5, transfer it to a 100ml hydrothermal kettle for hydrothermal reaction, heat it at 180°C for 24 hours, and after natural cooling, centrifuge at 5000rpm for 10min, wash with deionized water and ethanol three times, Dry in vacuum at ℃ for 24h. If this is done, and then directly annealed, MoO can be obtained 2 Composite graphene material, graphene accounts for MoO 2 3.1% of the mass of composite g...

Embodiment 2

[0035] 10 mg of graphene oxide microchips were dispersed in 15 ml of deionized water for 0.5 h using a cell pulverizer to obtain a 0.67 mg / ml graphene oxide dispersion. Dissolve 0.84g of sodium molybdate dihydrate and 2.1g of sodium salicylate in 31ml of deionized water respectively, stir magnetically for 10min to fully dissolve it, and then mix it with the graphene oxide dispersion to obtain a mixed solution. Mo in solution 2+ The molar ratio to the capping agent is 0.5:5, and the concentration of the capping agent in the mixed solution is 0.28mol / L. The pH was adjusted to 1.5 with hydrochloric acid, transferred to a 50ml hydrothermal kettle, heated at 180°C for 24h, cooled naturally, centrifuged at 5000rpm for 10min, washed with deionized water and ethanol three times, and dried in vacuum at 80°C for 24h. If you do this, you can get MoO by annealing directly. 2 Composite graphene material, graphene accounts for MoO 2 2.2% of the mass of composite graphene. The vacuum-dri...

Embodiment 3

[0038] 22 mg of graphene oxide microchips were dispersed in 20 ml of deionized water for 0.5 h using a cell grinder to obtain a 1.1 mg / ml graphene oxide dispersion. Dissolve 0.84g of sodium molybdate dihydrate and 2.1g of sodium salicylate in 20ml of deionized water, stir magnetically for 10min to fully dissolve it, and then mix it with the graphene oxide dispersion to obtain a mixed solution. Mo in solution 2+ The molar ratio to the capping agent is 1.5:3, and the concentration of the capping agent in the mixed solution is 0.33mol / L. The pH was adjusted to 1.5 with hydrochloric acid, transferred to a 50ml hydrothermal kettle, heated at 180°C for 24h, naturally cooled, centrifuged at 5000rpm for 10min, washed with deionized water and ethanol three times, and dried in vacuum at 80°C for 24h. If this is done, and then directly annealed, MoO can be obtained 2 Composite graphene material, graphene accounts for MoO 2 4.7% of the mass of composite graphene. The vacuum-dried samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com