Method for preparing high-quality gallium nitride nano powder

A nano-gallium nitride high-quality technology, applied in nanotechnology, nanotechnology, nitrogen-metal/silicon/boron binary compounds, etc., can solve the problems of low crystallinity quality of GaN products and limited application range of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

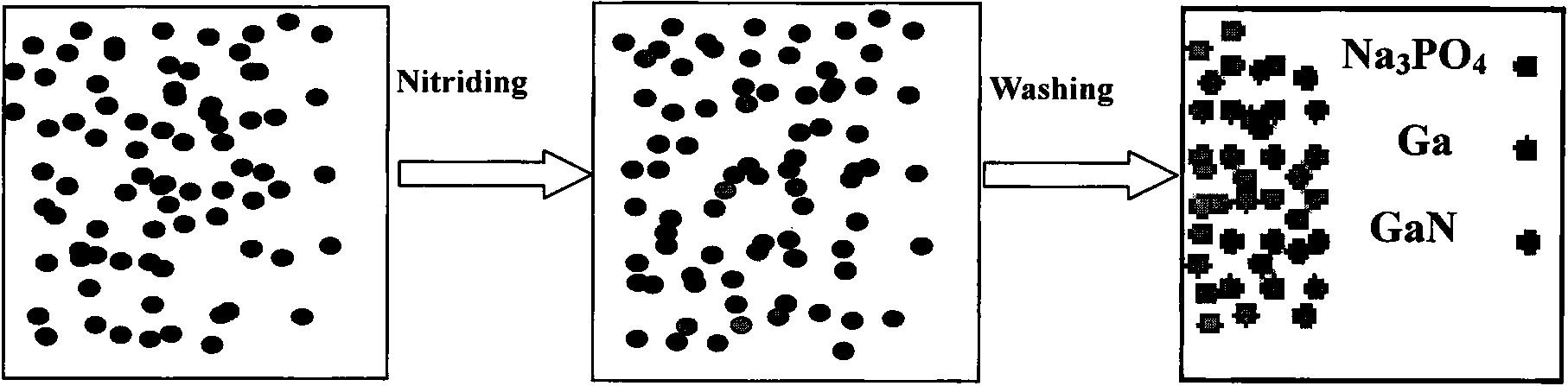

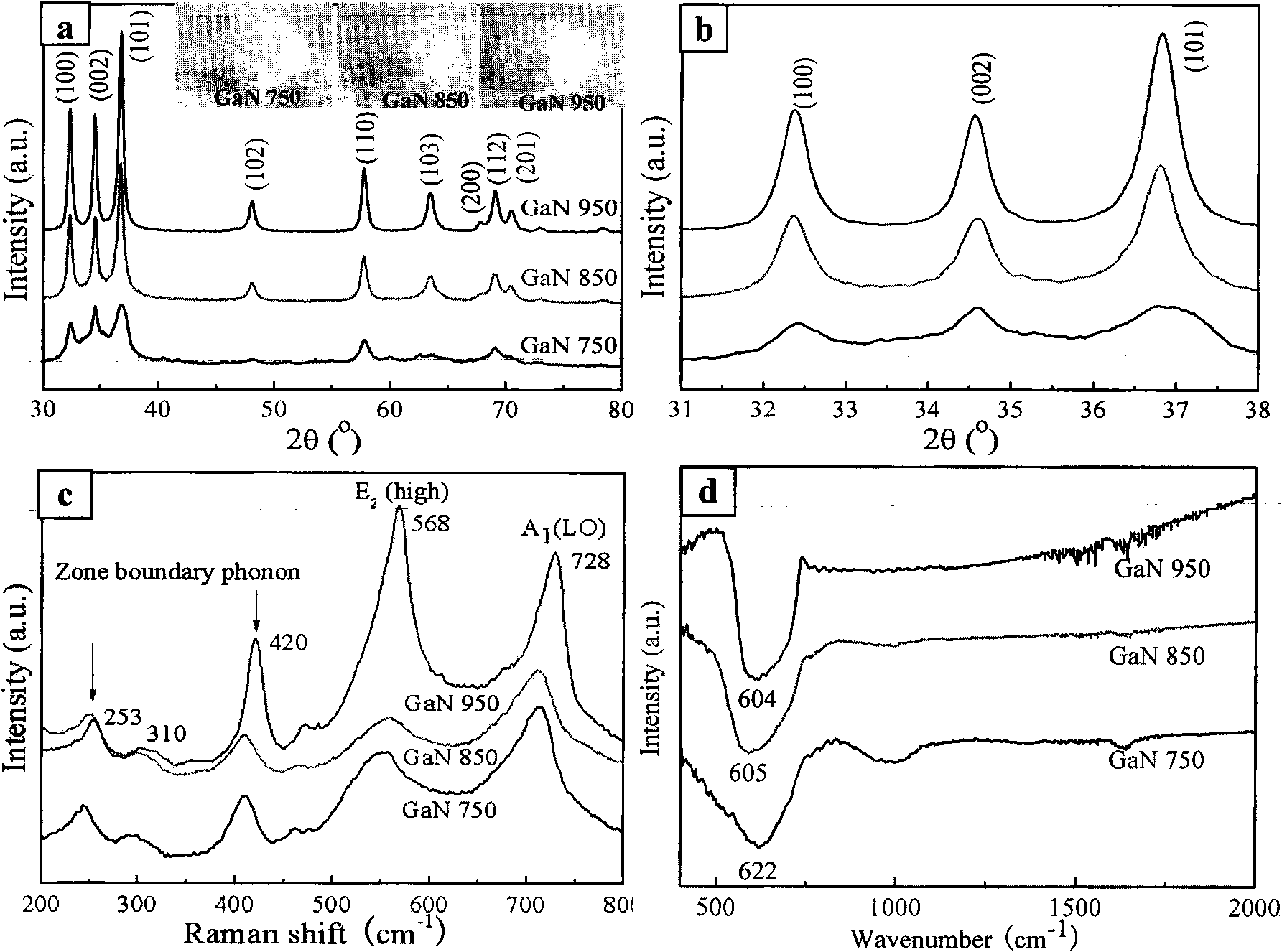

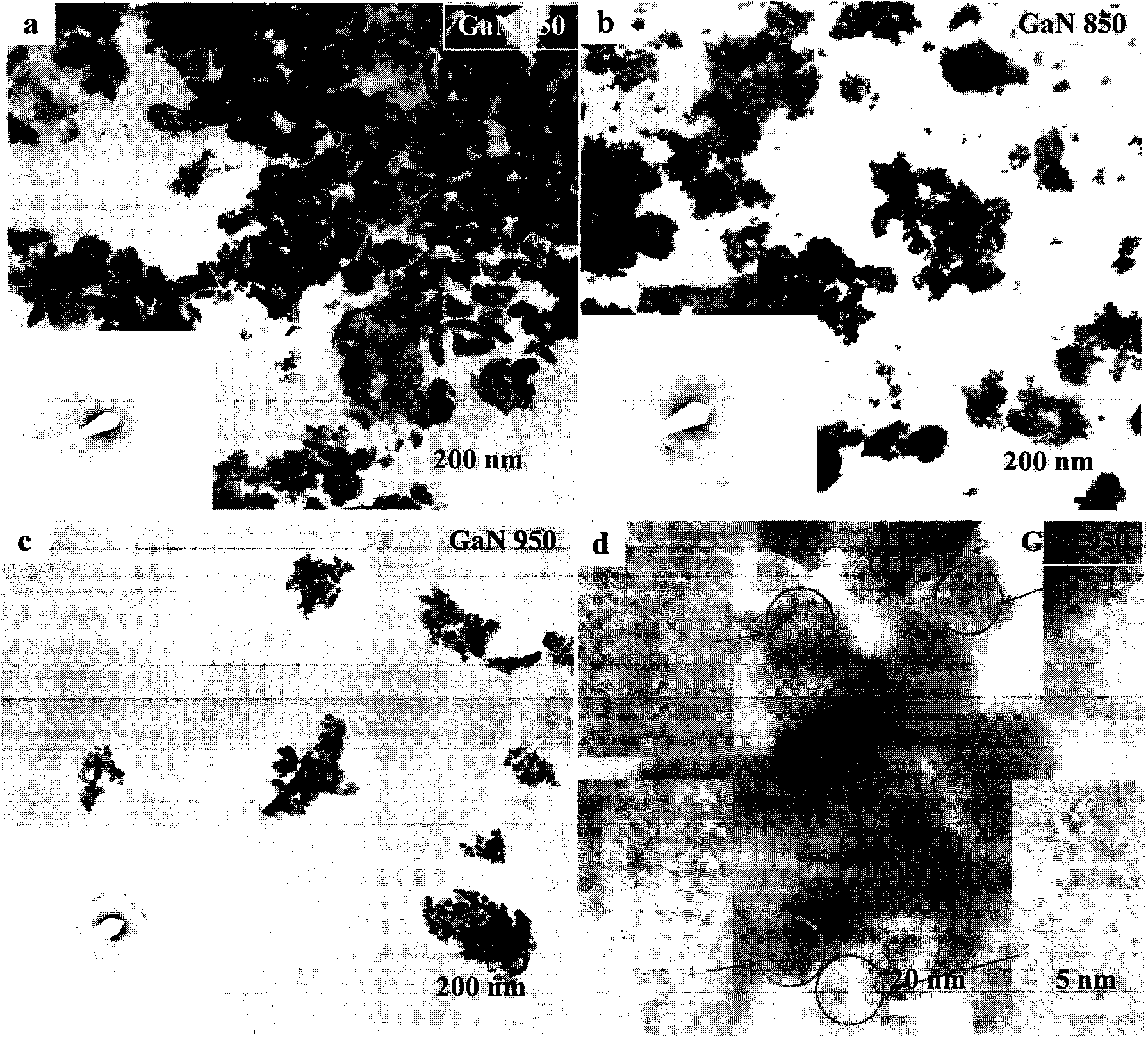

[0010] Thoroughly grind 1 g of metal Ga and 3 g of sodium phosphate at 29 °C, and then nitride the mixture of metal Ga and sodium phosphate in a tube furnace at 750 °C for three hours, followed by repeated washing of the nitrided mixture with distilled water. Sodium phosphate is removed, and finally pure GaN powder is obtained. The product is named GaN750, and the characterization of the product is as follows figure 2 and image 3 shown.

Embodiment 2

[0012] Fully grind metal Ga and sodium phosphate mixture at a ratio of 1:3 at 29°C, then nitride the uniformly mixed metal Ga and sodium phosphate mixture in a tube furnace at a temperature of 850°C with ammonia gas, and then rinse repeatedly with distilled water The nitridated mixture washes off the sodium phosphate, and finally a pure GaN powder is obtained. The product is named GaN850, and the characterization of the product is as follows figure 2 and image 3 shown.

Embodiment 3

[0014] Fully grind metal Ga and sodium phosphate mixture at a ratio of 1:3 at 29°C, and then nitrogenize the uniformly mixed metal Ga and sodium phosphate mixture with ammonia gas in a tube furnace at a temperature of 950°C, and then rinse repeatedly with distilled water The nitridated mixture washes off the sodium phosphate, and finally a pure GaN powder is obtained. The product is named GaN950, and the characterization of the product is as follows figure 2 and image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com