Activated basalt powder used as cement admixture and preparation method thereof

A technology of basalt powder and mixed material, which is applied in the field of building materials, can solve the problems of high grinding cost, high power consumption and poor grindability, etc., and achieves the effect of increasing the content of fine powder, excellent product performance and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

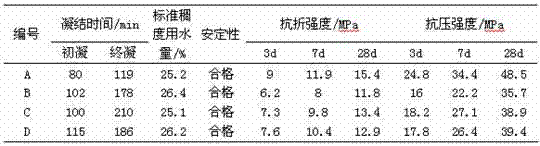

Embodiment 1

[0030] The raw material of Emeishan basalt is crushed repeatedly step by step with a jaw crusher until the maximum particle size is ≤3.15mm; the experimental ball mill is used for grinding for 60 minutes; ). Prepare and maintain according to GB / T 17671-1999 "Cement Mortar Strength Test Method", and take out the test block at the corresponding age to measure the strength of cement mortar. 23% equivalent replacement of cement clinker, initial setting 105min, final setting 158min, the stability is qualified, the compressive / flexural strength of activated basalt mortar 3d, 7d and 28d are 24.1 / 5.3, 34.5 / 5.7, 43.2 / 6.9 respectively. It fully complies with the strength requirements of pozzolanic Portland cement 42.5R in GB175-2007 "General Portland Cement".

Embodiment 2

[0032]The raw material of Emeishan basalt is crushed repeatedly step by step with a jaw crusher until the maximum particle size is ≤3.15mm; the experimental ball mill is used for grinding for 50 minutes; ). Prepare and maintain according to GB / T 17671-1999 "Cement Mortar Strength Test Method", and take out the test block at the corresponding age to measure the strength of cement mortar. 30% equivalent replacement of cement clinker, initial setting 115min, final setting 165min, the stability is qualified, the compressive / flexural strength of activated basalt mortar 3d, 7d and 28d are 19.3 / 4.2, 27.5 / 5.5, 36.2 / 6.6 respectively. It fully complies with the strength requirements of pozzolanic Portland cement 32.5R in GB175-2007 "General Portland Cement".

Embodiment 3

[0034] The raw material of Mount Emei basalt was crushed repeatedly step by step with a jaw crusher until the maximum particle size was ≤3.85mm; the ball mill was used for grinding for 65 minutes, and the grinding aid was added in three times during the grinding process. That is, 0.15% of the raw material of Emeishan basalt); to obtain the finished product (fineness 80μm sieve allowance ≤ 3%). Prepare and maintain according to GB / T 17671-1999 "Cement Mortar Strength Test Method", and take out the test block at the corresponding age to measure the strength of cement mortar. 25% equivalent replacement of cement clinker, initial setting 97min, final setting 123min, the stability is qualified, the strength of activated basalt mortar 3d, 7d and 28d are 20.5 / 4.5, 30.1 / 5.9, 39.5 / 7.1 respectively. It fully complies with the strength requirements of pozzolanic Portland cement 32.5R in GB175-2007 "General Portland Cement";

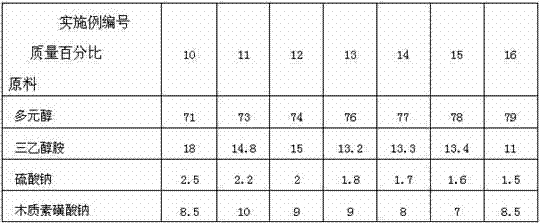

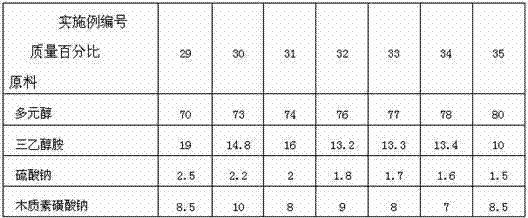

[0035] The grinding aid is composed of 70% to 80% of polyol, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com