High-salt non-degradable saccharin industrial wastewater and gas treatment method and device

A technology for industrial wastewater and waste gas treatment, which is applied in food industry wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., and can solve the problems of electrodialysis systems that are difficult to operate stably for a long time, increase energy consumption, and have many impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for treating high-salt refractory saccharin industrial wastewater and waste gas is characterized in that it is carried out according to the following steps:

[0045] (1) Add excessive iron shavings to the acidic wastewater containing copper ions to precipitate copper ions in the acidic wastewater; the amount of iron shavings added to the acidic wastewater: add 1 mol of iron ions to 1 mol of copper ions;

[0046] (2) After neutralizing the supernatant and alkaline wastewater from (1), adjust the pH between 7 and precipitate methyl anthranilate at a temperature of 12°C, and recover the methyl anthranilate for reuse into the production process;

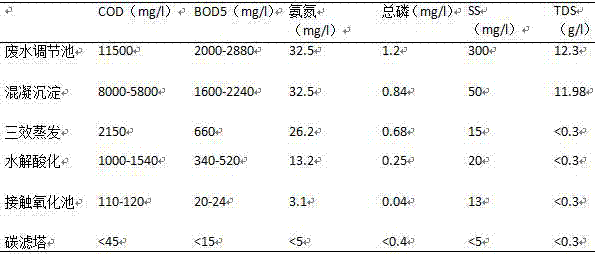

[0047] (3) Perform multi-stage flocculation and precipitation of mixed wastewater to remove COD, suspended and ammonia nitrogen substances in the wastewater; the flocculation and precipitation refers to the adjustment of wastewater after adding polyferric (PFS) and flocculant hydroxyethyl lentin gum solution After the pH...

Embodiment 2

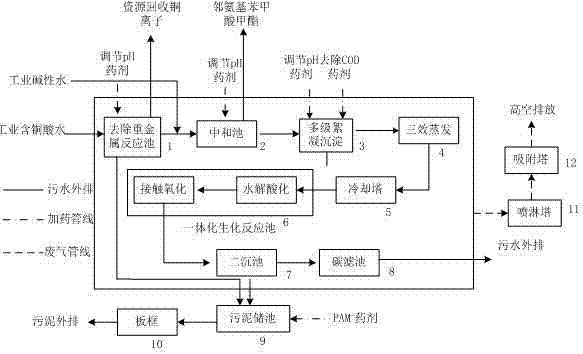

[0053] The device used for the treatment of high-salt refractory saccharin industrial wastewater and waste gas includes a metal removal reaction tank; an acid-base neutralization tank, a secondary flocculation sedimentation tank, a three-effect evaporation crystallization device, an integrated biological treatment tank, and an activated carbon filter Pool, sedimentation tank, mud storage tank, plate and frame filter press, alkaline spray tower, activated carbon adsorption tower; among them, heavy metal removal reaction tank 1 and acid-base neutralization tank 2, secondary flocculation sedimentation tank 3, three-effect evaporation The crystallization device 4, the cooling tower 5, the integrated biological pool 6, the sedimentation tank 7, and the activated carbon filter tank 8 are connected successively; The sludge pump enters the sludge storage tank 9, and the sludge in the sludge storage tank enters the plate and frame filter press 10 through the sludge pump; the alkaline sp...

Embodiment 3

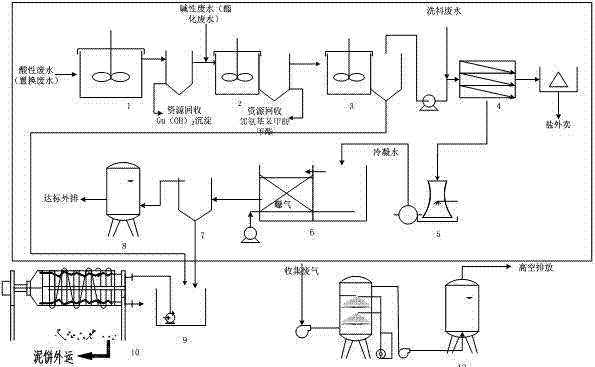

[0055] In a factory producing saccharin, the waste water produced during its reproduction mainly consists of three parts: acid waste water (acid waste water containing copper ions), alkaline waste water and washing waste water. Firstly, iron shavings are added to the acidic wastewater, and the molar number of iron content added is slightly greater than the amount of copper ions contained in the acidic wastewater, so that all the copper ions in the wastewater are precipitated, and the precipitated copper ions can be recovered and reused. system; then neutralize the wastewater and alkaline wastewater after copper removal, after the reaction, the wastewater shows acidity, and then adjust it by adding enhanced sodium oxide. After the pH of the wastewater is adjusted to between 6-8, the temperature is Methyl anthranilate is precipitated at 12-15°C, and the precipitated methyl anthranilate is recovered and reused in the system, as shown in the following table:

[0056] (1) In the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com