A method of co3o4 nanowire doping sn

A nanowire, oleylamine technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of improving electrical conductivity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

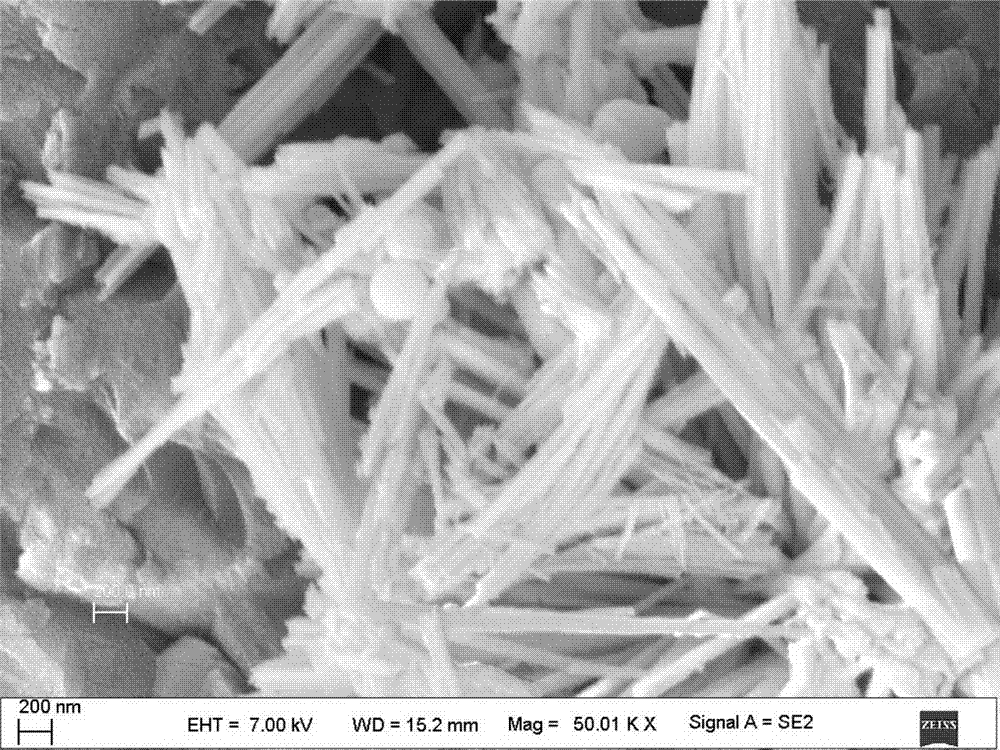

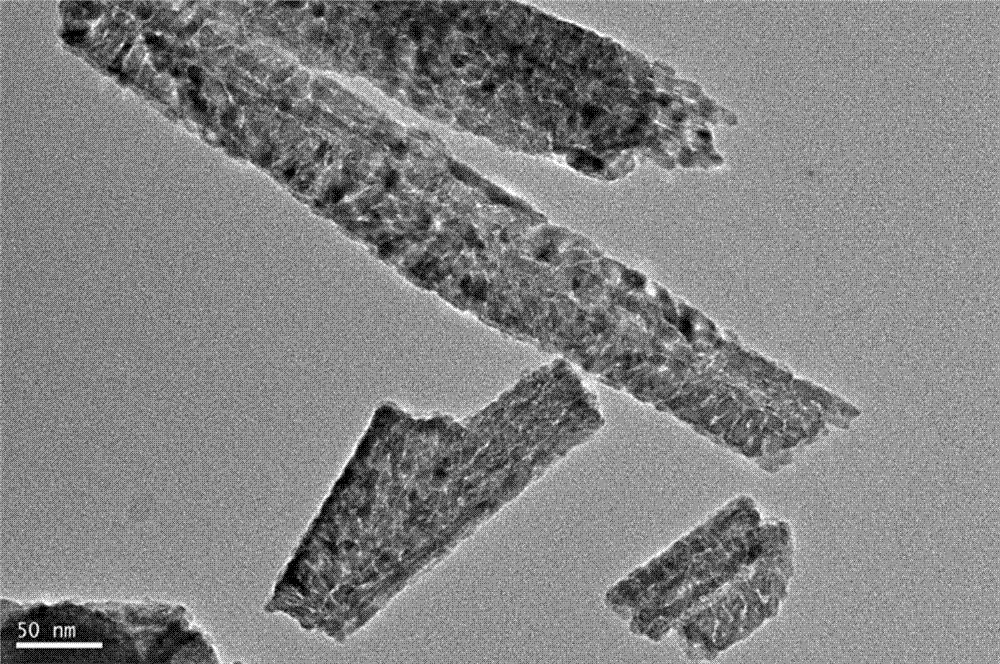

[0024] 0.3g Co(NO 3 ) 2 ·6H 2 O (1mmol) and 0.06g CO(NH 2 ) 2 (1mmol) were dissolved in 10mL twice distilled water to form a uniform solution, and CO(NH 2 ) 2 The solution was added dropwise to the Co(NO 3 ) 2 solution, and then the mixed solution was transferred to a high-pressure reactor. Put the autoclave into an oven, control the reaction temperature to 95° C., and take out the autoclave after hydrothermal reaction for 6 hours, and cool it for 30 minutes. A pink precipitate was obtained by filtering with a 450 μm mixed cellulose membrane, and the obtained precipitate was washed several times with double distilled water and absolute ethanol in sequence, and then dried at 60° C. for 6 hours to obtain a pink precursor. Then put the pink precursor into the tube furnace, the temperature is raised to 200°C at a rate of 1°C / min, and kept at 200°C for 30 minutes to obtain a black powder, which is Co 3 o 4 Nanowires.

[0025] 0.05g Co 3 o 4 Nanowires (0.2mmol), 480μL ...

Embodiment 2

[0027] Weigh 0.24g CoCl 2 ·6H 2 O(1mmol) and 0.3g CO(NH 2 ) 2 (5mmol) were dissolved in 10mL twice distilled water to form a uniform solution. CO(NH 2 ) 2 The solution was added dropwise to the CoCl 2 solution, and then the mixed solution was transferred to a high-pressure reactor. Put the autoclave into an oven, control the reaction temperature to 110° C., and take out the autoclave after hydrothermal reaction for 8 hours, and cool it for 30 minutes. A pink precipitate was obtained by filtering with a 450 μm mixed cellulose membrane, and the obtained precipitate was washed several times with double distilled water and absolute ethanol in sequence, and then dried at 60° C. for 8 hours to obtain a pink precursor. Then put the pink precursor into the tube furnace, the temperature is raised to 250°C at a rate of 1°C / min, and kept at 250°C for 60 minutes to obtain a black powder, which is Co 3 o 4 Nanowires.

[0028] 0.05g Co 3 o 4 Nanowires (0.2mmol), 385μL oleylami...

Embodiment 3

[0030] Weigh 0.3g Co(NO 3 ) 2 ·6H 2 O(1mmol) and 0.3g CO(NH 2 ) 2 (5mmol) were dissolved in 10mL twice distilled water to form a uniform solution. CO(NH 2 ) 2 The solution was added dropwise to the Co(NO 3 ) 2 solution, and then the mixed solution was transferred to a high-pressure reactor. Put the autoclave into an oven, control the reaction temperature to 120° C., and take out the autoclave after hydrothermal reaction for 8 hours, and cool it for 30 minutes. A pink precipitate was obtained by filtering with a 450 μm mixed cellulose membrane, and the obtained precipitate was washed several times with double distilled water and absolute ethanol in sequence, and then dried at 60° C. for 10 hours to obtain a pink precursor. Then put the pink precursor into a tube furnace, raise the temperature to 300°C at a rate of 2°C / min, and keep it at 300°C for 100 minutes to obtain a black powder, which is Co 3 o 4 Nanowires.

[0031] 0.05g Co 3 o 4 Nanowires (0.2mmol), 480μL ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com