Preparation method of novel zinc oxide material

A new type of zinc oxide technology, applied in the field of preparation of new zinc oxide materials, can solve the problems of high replacement cost of preparation process, complicated preparation process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a method for preparing a novel zinc oxide material, the method steps are as follows:

[0035] S1: Take the sapphire substrate as the growth substrate, and clean it; in this embodiment, in order to effectively remove the oil stain on the surface of the substrate, it is successively ultrasonicated through acetone, isopropanol, anhydrous formaldehyde, and deionized water. After cleaning, blow dry with nitrogen gas for later use;

[0036] S2: Select ZnO as the target material, adopt pulsed laser deposition technology, feed oxygen flow, and control the growth at a specific temperature for a period of time, after the growth is completed, naturally cool to room temperature, and then obtain the ZnO seed layer; in this embodiment Among them, a 248nm KrF excimer laser is used as the laser source, the working frequency is 2HZ, the laser energy is 300mJ, ZnO is used as the target material, sapphire is used as the substrate, and the background vacuum is set ...

Embodiment 2

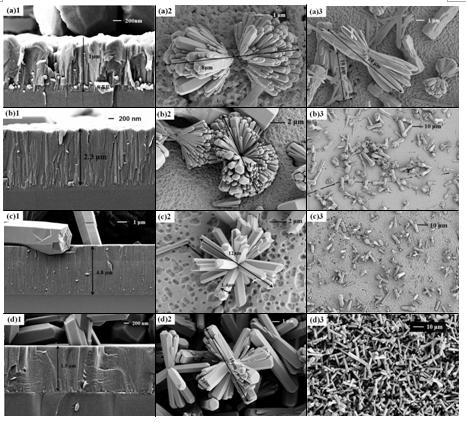

[0043] This example provides another preparation method of a new type of zinc oxide material, aiming to explore the influence of different precursor concentrations on the morphology of ZnO. On the basis of the above embodiments, a 200nm thick sapphire substrate is selected, and a ZnO seed layer is grown on the substrate. In order to explore the effect of different precursor concentrations on the morphology of ZnO, the reaction temperature in S3 and S4 was set at 95 °C, the reaction time was set at 5 h and the zinc acetate (Zn(CH 3 COO) 2 2H 2 O) and HMTA configuration concentration ratio of 1:1, the ZnO nanomaterial morphology was observed when the concentration of zinc acetate was 6.25 mM, 15 mM, 25 mM and 30 mM, respectively, as figure 1 As described in (a)1-(d)1, as the precursor concentration increased from 6.25 mM to 30 mM, the thickness of a film grown on the seed layer increased from 1 µm to 4.8 µm, but continued to increase When the precursor concentration is lowere...

Embodiment 3

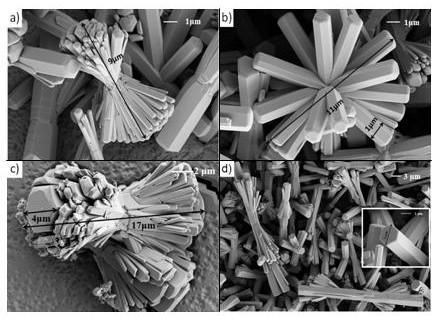

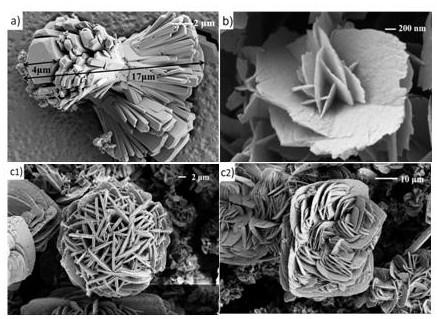

[0046] This example provides another preparation method of a new type of zinc oxide material, aiming to explore the influence of different reaction times on the morphology of ZnO. On the basis of the above examples, in order to explore the influence of different reaction times on the morphology of ZnO, the concentration of zinc acetate in S3 and S4 was configured as 20 mM, and when the reaction temperature was set at 95°C, the reaction times were 5h, 6h, At 8h and 10h, the shape and aspect ratio of ZnO nanorods were observed. Such as figure 2 As shown in (a), when the reaction time is 5 h, the nanorods are hourglass-shaped with a short size and a length of about 9 μm, and the shape of the nanorod tip is irregular; as figure 2 As shown in (b), when the reaction time is 6 h, the ZnO nanorods are regular-shaped nanostyles, the length increases to 11 μm, and the diameter is uniformly 1 μm, and the top of the nanorods turns into a typical ZnO hexagonal prism shape, and the diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com