Bending die with self-lubricating pits and preparation method

A bending die and self-lubricating technology, applied in the direction of forming tools, manufacturing tools, welding equipment, etc., can solve the problems of reducing the machining accuracy of the bending machine, reducing the machining accuracy, aggravating the wear of the mold, and improving the service life and comprehensive performance. , Improve reliability and service life, improve the effect of anti-friction and anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In a typical embodiment of the present disclosure, such as Figure 1-Figure 8 As shown, a bending die with self-lubricating pits is given.

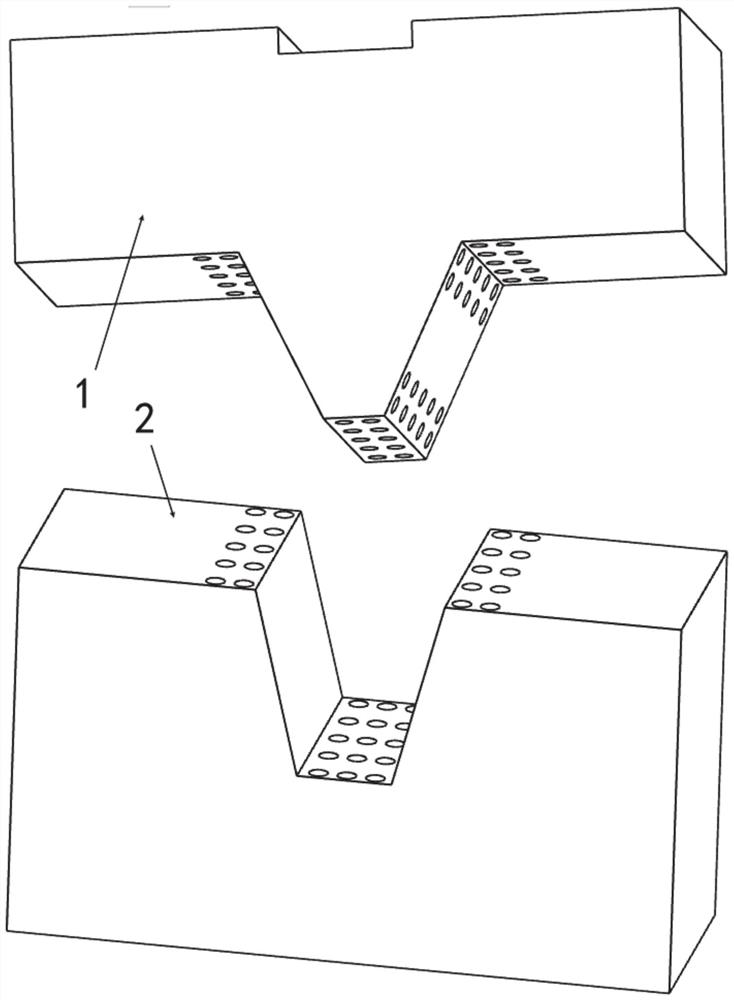

[0040] It mainly includes punch 1 (upper die) and die 2 (lower die). The die 2 is located under the punch 1. During work, the sheet or workpiece is located between the punch 1 and the die 2. The punch 1 is in the power system Under the control of the reciprocating motion, the bending sheet or workpiece obtains a specific shape.

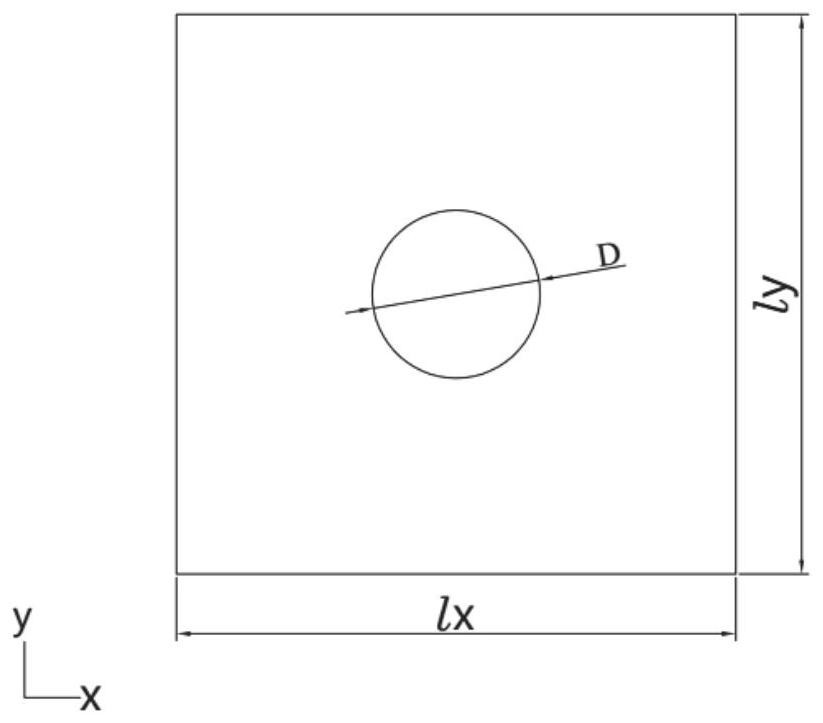

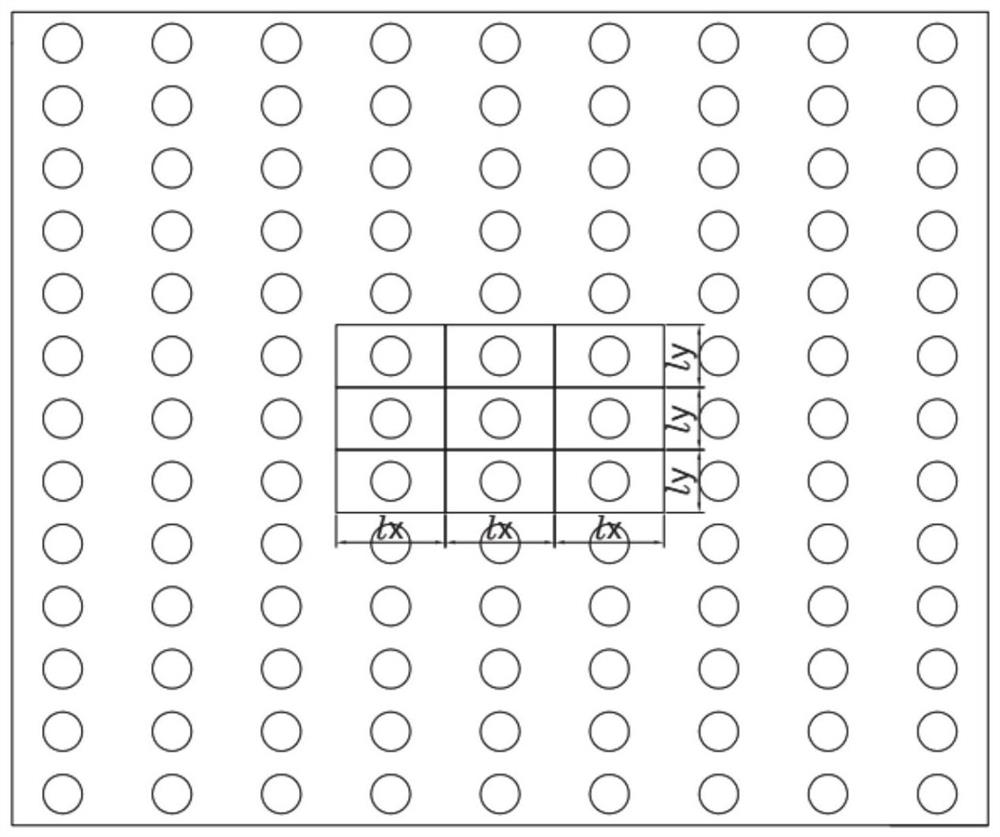

[0041] The punch 1 and the die 2 are in contact with the sheet material or the workpiece, and the pit texture with a specific arrangement is processed on the working surface of the punch 1 and the die 2 where the friction and wear are relatively large. The structure is a micro-dimple structure, and the solid lubricant 5 is filled in the micro-dimples.

[0042] In this embodiment, the areas with greater friction and wear of the bending die are the bending feature processing area and the arc feature proces...

Embodiment 2

[0053] In another typical embodiment of the present disclosure, as Figure 1-Figure 8 As shown, a preparation method of a bending die with self-lubricating pits is given, which is used to prepare the bending die with self-lubricating pits as described in Example 1.

[0054] Include the following steps:

[0055] Obtain the friction and wear state of the working surface of the mold, and screen the area of the pit texture to be processed;

[0056] Grinding and cleaning the working surface of the mold, processing the pit texture in the area to be processed, and making the pit texture in the same area arranged in an array;

[0057] After cleaning the processed pit texture, fill it with solid lubricant.

[0058] Further, according to the friction and wear of the mold, the pit texture is arranged for the processing position of the mold corresponding to the bending feature.

[0059] Specifically, for the above-mentioned preparation method, the following detailed steps are include...

Embodiment 3

[0067] In another typical embodiment of the present disclosure, as Figure 1-Figure 8 As shown, a method for preparing a bending die with self-lubricating pits is given, wherein the bending die is an inverted trapezoidal bending die.

[0068] Such as Figure 6 Shown, its preparation method comprises the following steps:

[0069] (1) According to the shape and structure characteristics of the inverted trapezoidal bending die and the friction and wear state under its actual working conditions, it is determined that the corners of the four surfaces a, b, d, and e of the inverted trapezoidal bending machine punch 7 are near the corners (corner Points cannot be processed directly) and all areas of the c surface are processed with micro pits, near the corners of the four surfaces f, g, i, j of the inverted trapezoidal bending machine die 9 (the corner points cannot be directly processed) and all areas of the h surface Processing of micro pits, the arrangement of micro pits is as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com