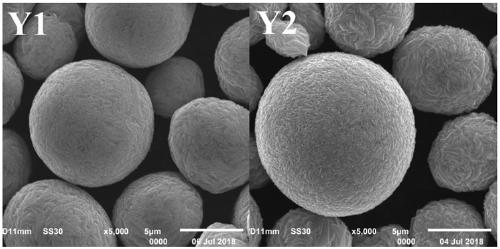

Spherical Co (II) Co (III) hydrotalcite like material and preparation method thereof

A hydrotalcite and spherical technology, which is applied in the field of spherical CoCo hydrotalcite-like materials and its preparation, can solve problems such as undiscovered, and achieve the effect of dense surface, good sphericity of product, and dense surface of sphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

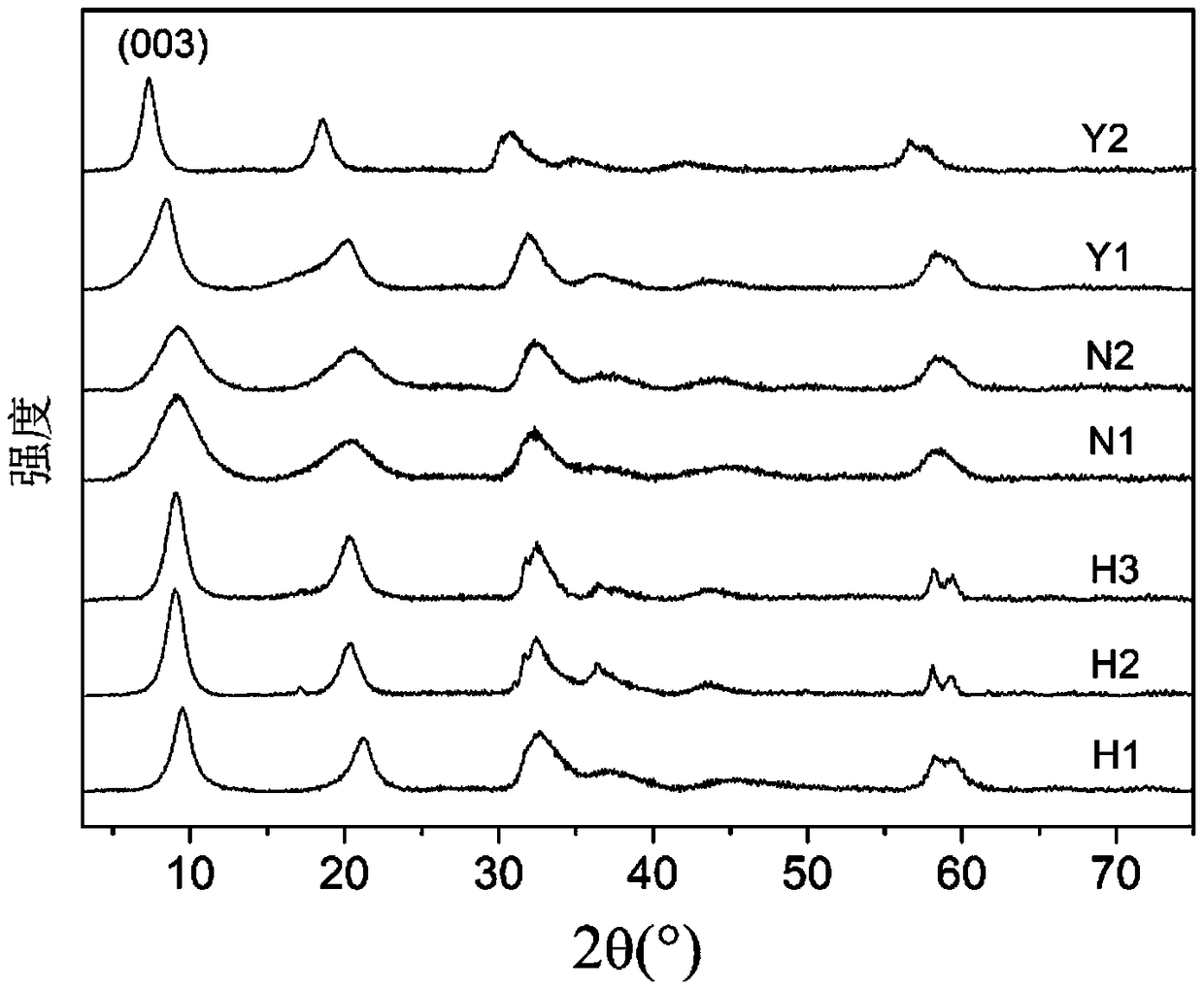

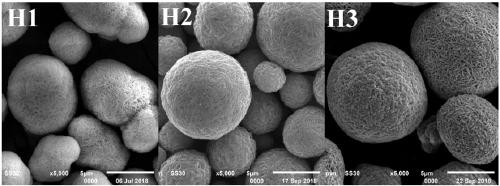

Embodiment 1

[0030] Prepare mixed solution A of 1mol / L cobalt nitrate and 0.2mol / L ammonium nitrate, prepare 0.1mol / LH 2 o 2 and 0.1mol / L sodium oxalate mixed solution B. Using the co-precipitation method, the A and B solutions were added to the 100mL sodium hydroxide bottom solution with an initial pH of 10 according to the flow rate of 6mL / min and 5mL / min, and the H was controlled during the process. 2 o 2 The molar ratio with cobalt salt is 1:12. During the reaction process, 2mol / L sodium hydroxide solution is continuously added to maintain the pH value of the reaction solution at about 10; The temperature was controlled at 55°C. After the reaction was completed, it was centrifuged, washed with a large amount of deionized water until the filter cake was neutral, and finally dried in vacuum at 70°C. The obtained sample was named H1, which is a spherical Co(II)Co(III) hydrotalcite material. The spherical Co(II) Co(III) hydrotalcite material is a layered double hydroxyl metal hydroxide...

Embodiment 2

[0033] Prepare mixed solution A of 1mol / L cobalt nitrate and 0.2mol / L ammonium nitrate, prepare 0.1mol / LH 2 o 2 and 0.1mol / L sodium oxalate mixed solution B. Using the co-precipitation method, the A and B solutions were added to the 100mL sodium hydroxide bottom solution with an initial pH of 10 according to the flow rate of 6mL / min and 6.67mL / min, and the H was controlled during the process. 2 o 2 The molar ratio with cobalt salt is 1:9. During the reaction process, 2mol / L sodium hydroxide solution is continuously added to maintain the pH value of the reaction solution at about 10; The temperature was controlled at 55°C. After the reaction, it was centrifuged, washed with a large amount of deionized water until the filter cake was neutral, and finally dried in vacuum at 70°C. The obtained sample was named H2, which is a spherical Co(II)Co(III) hydrotalcite material. The spherical Co(II) Co(III) hydrotalcite material is a layered double hydroxyl metal hydroxide formed by d...

Embodiment 3

[0036] Prepare mixed solution A of 1mol / L cobalt nitrate and 0.2mol / L ammonium nitrate, prepare 0.1mol / LH 2 o 2 and 0.1mol / L sodium oxalate mixed solution B. Using the co-precipitation method, the A and B solutions were added to the 100mL sodium hydroxide bottom solution with an initial pH of 10 according to the flow rate of 6mL / min and 10mL / min, and the H was controlled during the process. 2 o 2 The molar ratio with cobalt salt is 1:6. During the reaction process, 2mol / L sodium hydroxide solution is continuously added to maintain the pH value of the reaction solution at about 10; The temperature was controlled at 55°C. After the reaction, it was centrifuged, washed with a large amount of deionized water until the filter cake was neutral, and finally dried in vacuum at 70°C. The obtained sample was named H3, which is a spherical Co(II)Co(III) hydrotalcite material. The spherical Co(II) Co(III) hydrotalcite material is a layered double hydroxyl metal hydroxide formed by div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com