Mask plate and manufacturing method thereof

A mask and mask technology, which is applied in the semiconductor field, can solve the problems of poor mask quality and achieve the effects of superior structural performance, high wear resistance, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It can be seen from the background art that the quality of the mask plate provided by the prior art is relatively poor.

[0020] The analysis found that if impurities are attached to the mask, the pattern of the impurities will be transferred to the wafer, thereby affecting the performance and yield of devices fabricated on the wafer.

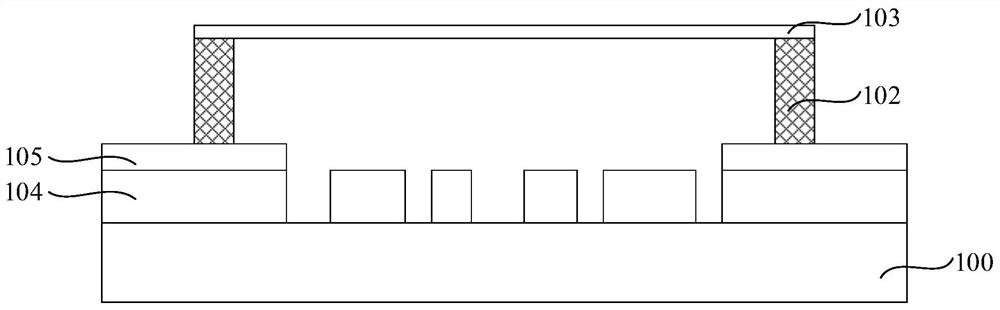

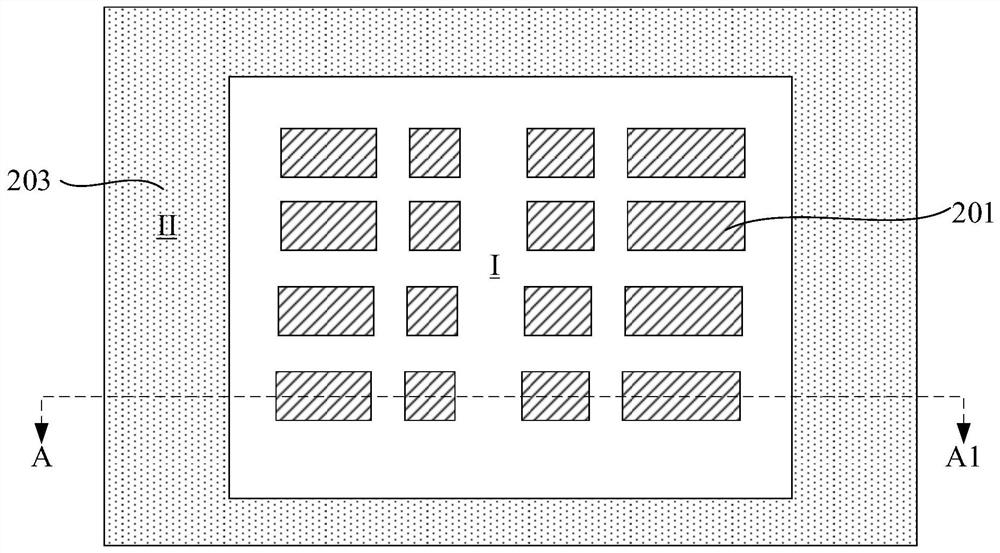

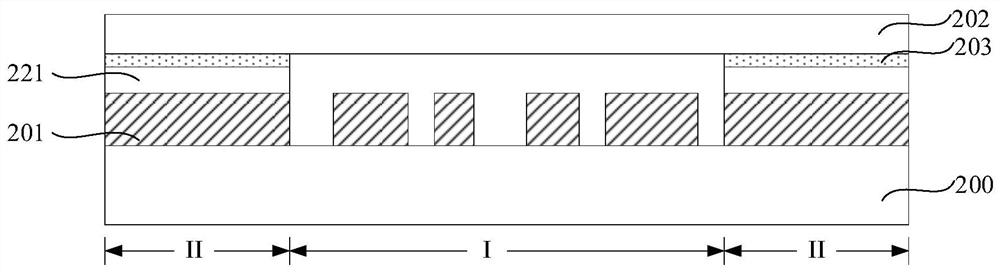

[0021] In order to better protect the mask during use and reduce the probability of impurities appearing on the mask, a mask that can prevent impurities from adhering is proposed. figure 1 is a schematic diagram of the cross-sectional structure of a mask, refer to figure 1 , the mask plate includes: a substrate 100 and a pattern metal layer on the substrate 100, the pattern metal layer includes a pattern area (not marked) and a peripheral area (not marked) surrounding the pattern area; a frame (frame) 102, the frame 102 It is located on the pattern metal layer of the peripheral area and surrounds the pattern area; a transparent film (pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com