A processing method and design system for surface micro-texture of stamping die

A technique for stamping dies and processing methods, which is applied in the field of processing methods and design systems for surface micro-textures of stamping dies, which can solve problems such as unsuitable high-strength plates, reduced die life, and sheet material thinning, and achieve friction-reducing and anti-wear effects Effect of improving, increasing standardization level, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] This embodiment provides a method for processing the surface micro-texture of a stamping die, including:

[0065] Carry out three-dimensional scanning of the stamping die to obtain the overall three-dimensional point cloud data of the stamping die;

[0066] According to the three-dimensional point cloud data, the three-dimensional shape characteristic parameters such as the curvature and the normal vector of each area on the surface of the stamping die are obtained;

[0067] According to the three-dimensional shape feature parameters, the boundary features are divided to determine the boundary conditions of each area on the surface of the stamping die;

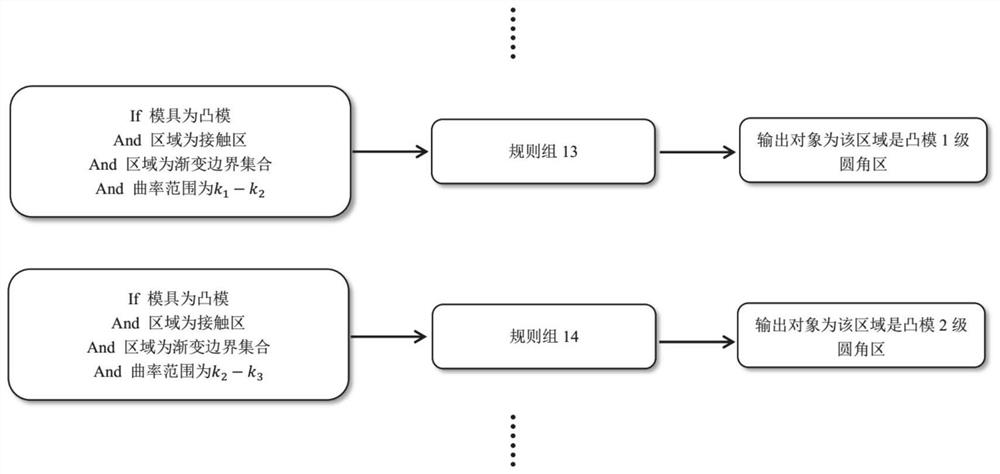

[0068] According to the boundary feature division and the three-dimensional shape feature parameters, the friction and wear area division of each area on the surface of the stamping die is carried out;

[0069] Carry out die stamping simulation, carry out orthogonal polynomial regression design on the performance param...

Embodiment 2

[0087] This embodiment provides a processing and design system for the surface micro-texture of a stamping die, including:

[0088] The data acquisition system is used to acquire the 3D point cloud data of the stamping die as a whole;

[0089] The three-dimensional shape characteristic parameter calculation system is used to calculate the three-dimensional shape characteristic parameters of the stamping die surface according to the three-dimensional point cloud data;

[0090] The boundary feature division system is used to divide the boundary features according to the three-dimensional shape feature parameters, and determine the boundary feature division parameters of each area on the surface of the stamping die;

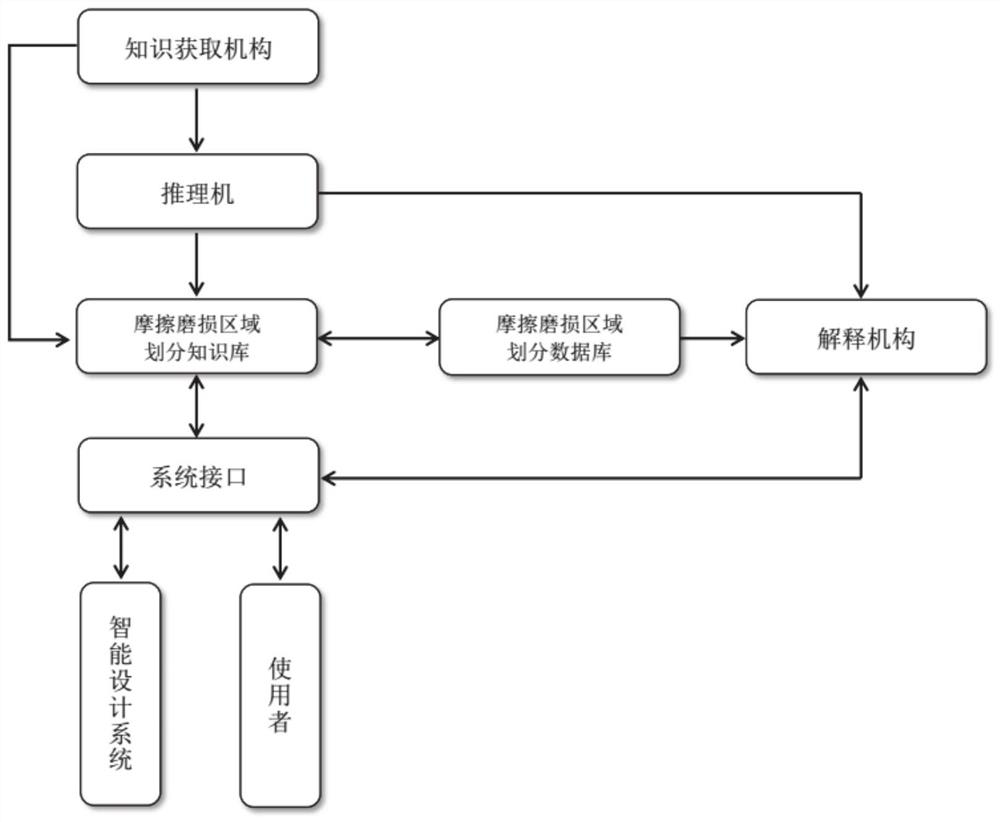

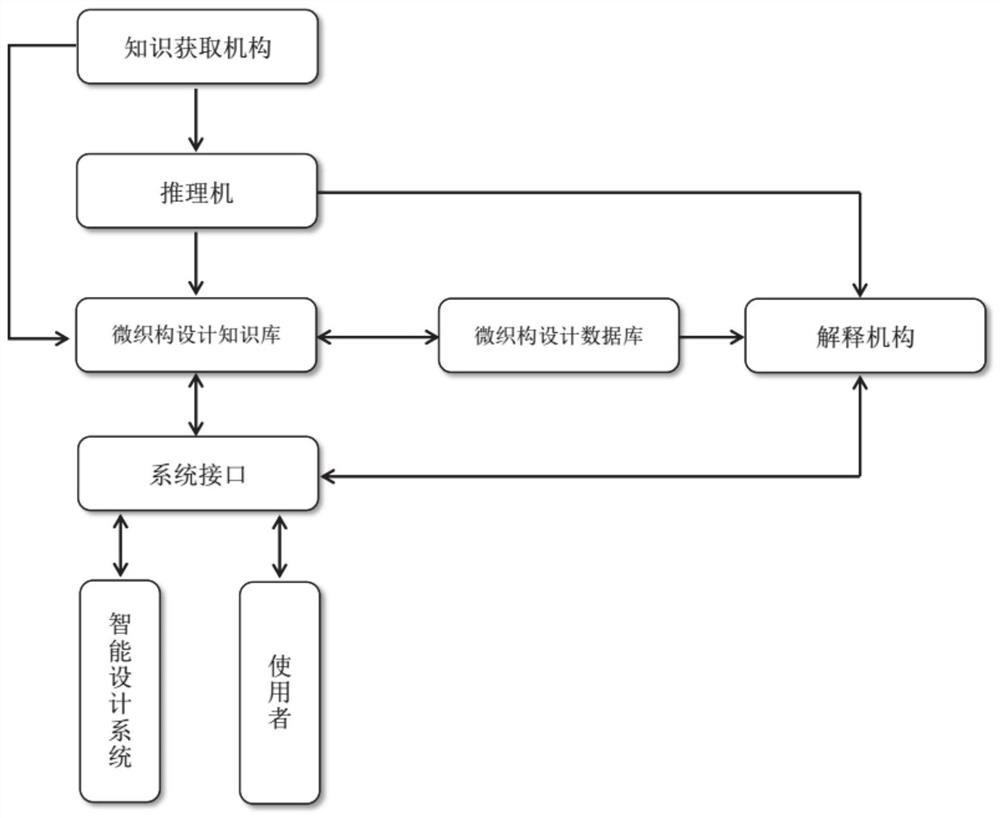

[0091] The friction and wear area division expert system is used to divide the friction and wear area of each area on the surface of the stamping die according to the boundary feature division parameters and the three-dimensional shape feature parameters, and obta...

Embodiment 3

[0110] In this embodiment, the stamping die for the air outlet valve of the automobile box cover with a relatively simple structure is selected for an example analysis, and the micro-protrusion texture and the micro-pit texture with reasonable parameters are processed on its surface. The processing method includes the following steps:

[0111] (1) Obtain the 3D point cloud data of the stamping die of the air outlet valve of the car interior box cover with a handheld laser 3D scanner, import it into the design system in STL format through the data acquisition system, and then transfer it to the 3D shape feature parameter calculation system to obtain it through program calculation Curvature, normal vector and other characteristic parameters of different regions.

[0112] (2) The curvature and normal vectors obtained in the 3D shape characteristic parameter calculation system are transferred to the boundary feature division system, and only the actual contact with the workpiece is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com