Method for promoting dispersion of nanofiller by utilizing stretching effect of pore wall of polymer foam material

A nano-filler and foaming material technology, which is applied in the field of polymer nanocomposite material preparation, can solve the problems of easily damaged filler morphology, complicated operation, and reduced filler performance, so as to improve physical and chemical properties, avoid complicated operation, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

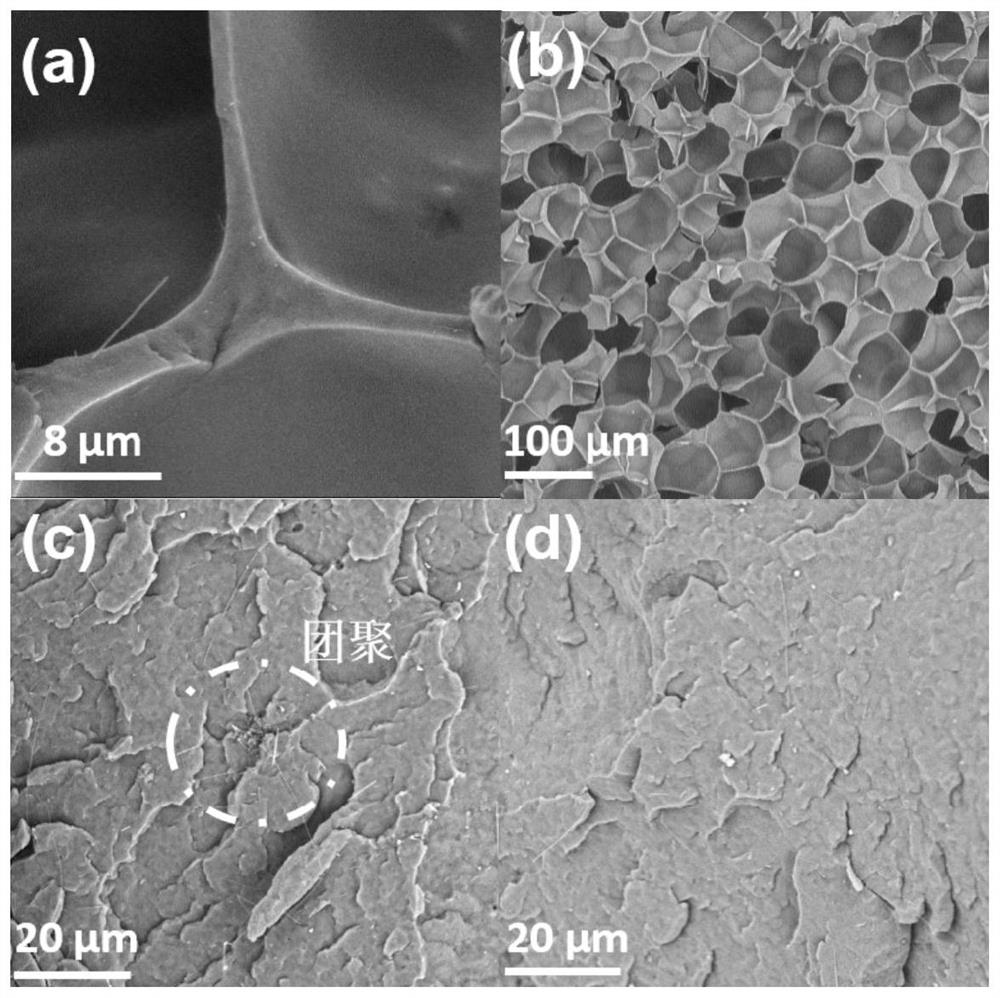

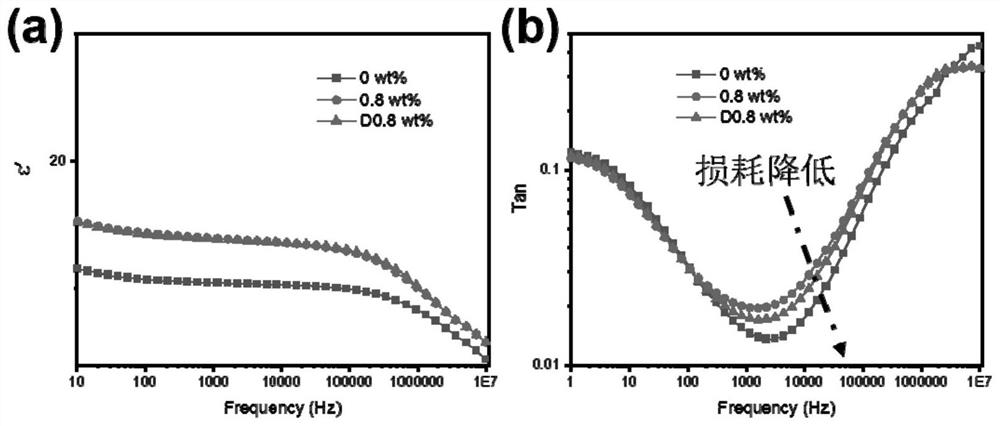

[0033] In this example, a method for promoting the dispersion of nanofillers by stretching the pore walls of polymer foam materials is provided to prepare CNF / PVDF nanocomposites with uniformly dispersed carbon-based conductive fillers and characterize their dielectric properties. The steps are as follows:

[0034] (1) Preparation of CNF / PVDF premix

[0035] ① Dry the carbon nanofiber (CNF) in vacuum at 80°C for 12 hours, and dry the polyvinylidene fluoride (PVDF) pellets in vacuum at 80°C for 4 hours;

[0036] ②Put the dried CNF and PVDF pellets into an internal mixer, and melt blend them for 90s at 200°C with a rotor speed of 50rpm (prolonging the melt blending time will lead to a significant decrease in the aspect ratio of CNF) to obtain CNF / PVDF premixture, the content of CNF in the premixture is 0.8wt%.

[0037] (2) Foaming

[0038] The CNF / PVDF premix was hot-pressed at 200°C to prepare a plate-shaped green body. The length and width of the green body were 13 mm and t...

Embodiment 2

[0049] In this example, a method for promoting the dispersion of nano fillers by using the stretching effect of the pore wall of the polymer foam material is provided to prepare a CNF / PVDF nanocomposite material with uniformly dispersed carbon-based conductive fillers and characterize its thermal conductivity. The steps are as follows:

[0050] (1) Preparation of CNF / PVDF premix

[0051] ① Vacuum-dry CNF at 80°C for 12 hours, and vacuum-dry PVDF pellets at 80°C for 4 hours;

[0052] ②Put the dried CNF and PVDF pellets into an internal mixer, and melt blend them for 90s at 200°C with a rotor speed of 50rpm to obtain a CNF / PVDF premix. The content of CNF in the premix is 10wt% .

[0053] (2) Foaming

[0054] The CNF / PVDF premix was hot-pressed at 200°C to prepare a plate-shaped green body. The length and width of the green body were 13 mm and the thickness was 3.5 mm. Raise the temperature of the molding and foaming equipment to 168°C, put the green body into the mold cavit...

Embodiment 3

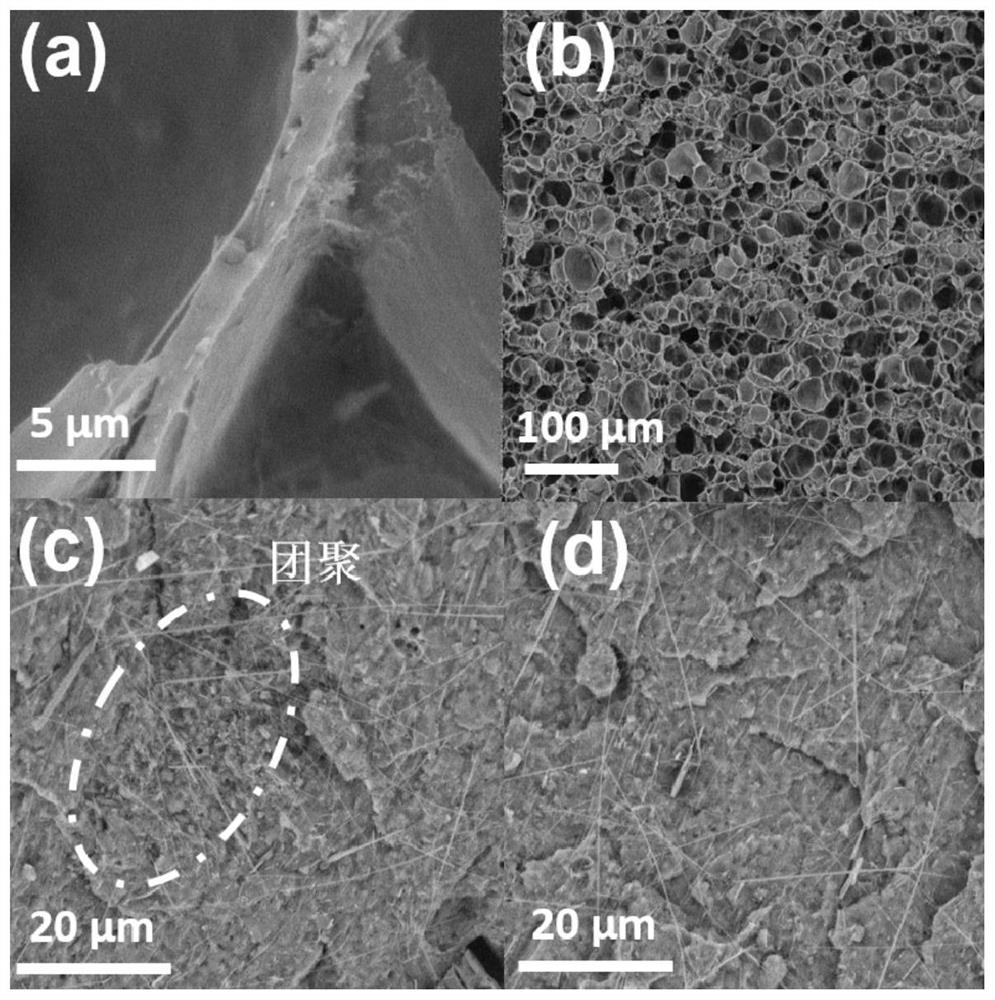

[0063] In this embodiment, a method for promoting the dispersion of nanofillers by stretching the pore wall of the polymer foam material is provided, and the CNF / TPU nanocomposite material with uniformly dispersed nanofillers is used for SEM characterization of the dispersion behavior of CNF. The steps are as follows:

[0064] (1) Preparation of CNF / TPU premix

[0065] ① Vacuum dry CNF at 80°C for 12 hours, and vacuum dry TPU pellets at 80°C for 4 hours;

[0066] ②Put the dried CNF and TPU pellets into an internal mixer, and melt blend them for 90s at 180°C with a rotor speed of 50rpm to obtain a CNF / TPU premix. The content of CNF in the premix is 8wt% .

[0067] (2) Foaming

[0068] The CNF / TPU premix was hot-pressed at 200° C. to prepare a plate-shaped green body. The length and width of the green body were 13 mm and the thickness was 3.5 mm. Raise the temperature of the molding and foaming equipment to 180°C, put the green body into the mold cavity, inject carbon dioxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com