Method for forming semiconductor device

A semiconductor and device technology, applied in the field of semiconductor device formation, can solve the problems of expensive, time-consuming, repeated exposure steps, etc., and achieve the effect of reducing process difficulty and production cost, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

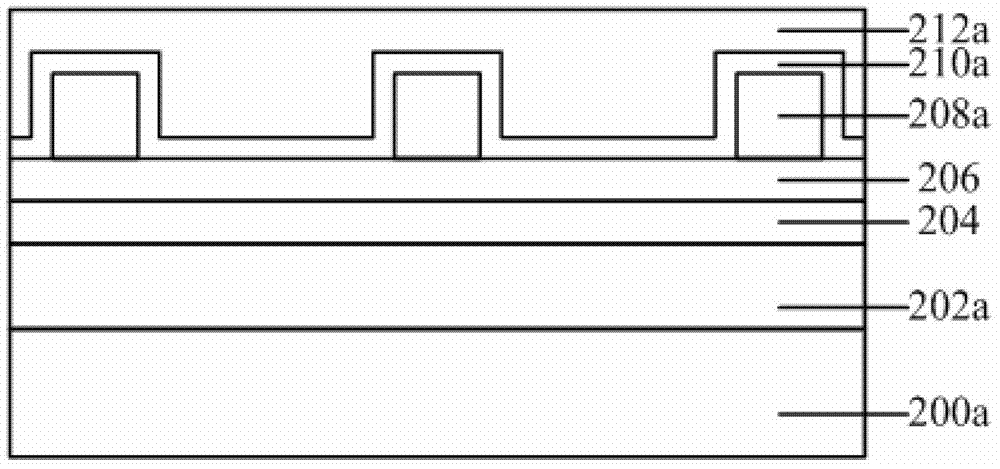

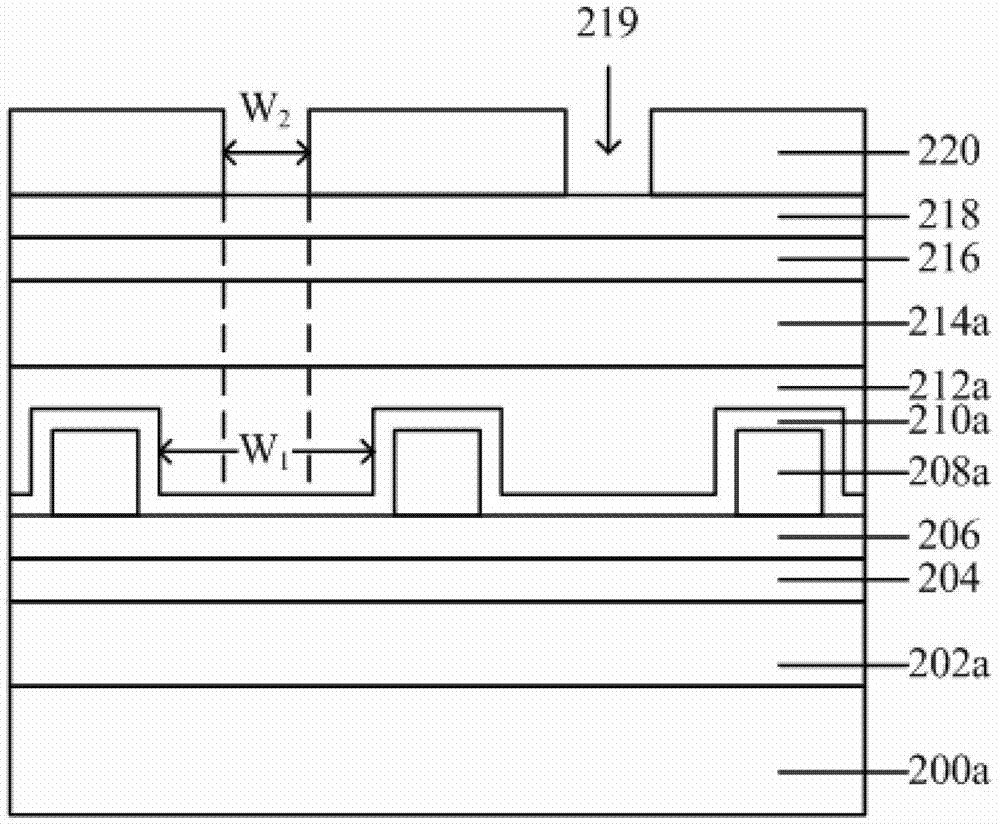

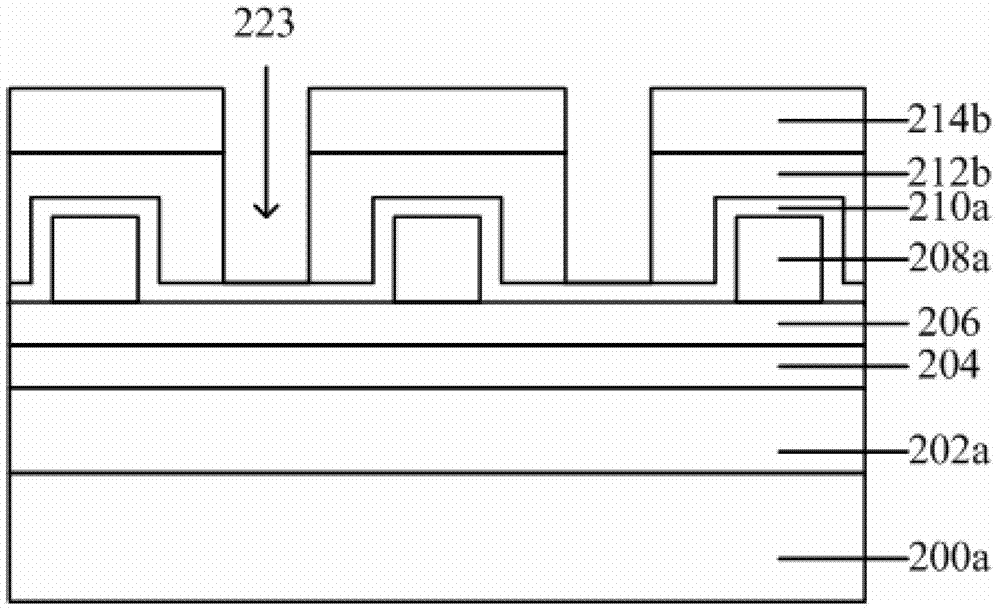

[0039] refer to figure 1 , providing a semiconductor substrate 200a, and forming a first mask layer on the semiconductor substrate 200a.

[0040] In this embodiment, the material of the semiconductor substrate 200a can be single crystal silicon, single crystal germanium or single crystal silicon germanium, silicon-on-insulator, III-V group element compounds, single crystal silicon carbide, etc. other materials.

[0041] In addition, a device structure (not shown in the figure) may also be formed in the semiconductor substrate 200a, and the device structure may be a device structure formed in a semiconductor front-end process, such as a MOS transistor.

[0042] In this embodiment, the first mask layer is a multi-layer structure, and forming the first mask layer on the semiconductor substrate 200a includes: sequentially forming an organic distribution layer 202a, a second mask layer on the semiconductor substrate 200a from bottom to top, Two hard mask layers 204, bottom anti-...

no. 2 example

[0081] refer to Figure 8 , providing a semiconductor substrate 300a, and forming a first mask layer on the semiconductor substrate 300a.

[0082] In this embodiment, the first mask layer is a multi-layer structure, and forming the first mask layer on the semiconductor substrate 300a includes: sequentially forming an organic distribution layer 302 on the semiconductor substrate 300a from bottom to top , a second hard mask layer 304 and a photoresist layer.

[0083] In this embodiment, please refer to the first embodiment for the structure and formation process of the semiconductor substrate 300 a , the organic distribution layer 302 , the second hard mask layer 304 and the photoresist layer, and details are not repeated here.

[0084] In another embodiment, after forming the second hard mask layer 304 and before forming the photoresist layer, forming a bottom anti-reflection layer on the second hard mask layer 304 may also be included. (not shown).

[0085] continue to refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com