Bearing/insulating/ablating all-in-one sandwich structure composite material and preparation method thereof

A composite material and sandwich structure technology, applied in the direction of layered products, etc., can solve the problems of affecting the thermal protection effect of the structural layer, poor thermal insulation performance of the structure, and affecting the use effect, etc., and achieve the improvement of interlayer shear strength and integrity Good, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1: Preparation of a bearing / insulation / ablation integrated sandwich structure composite material

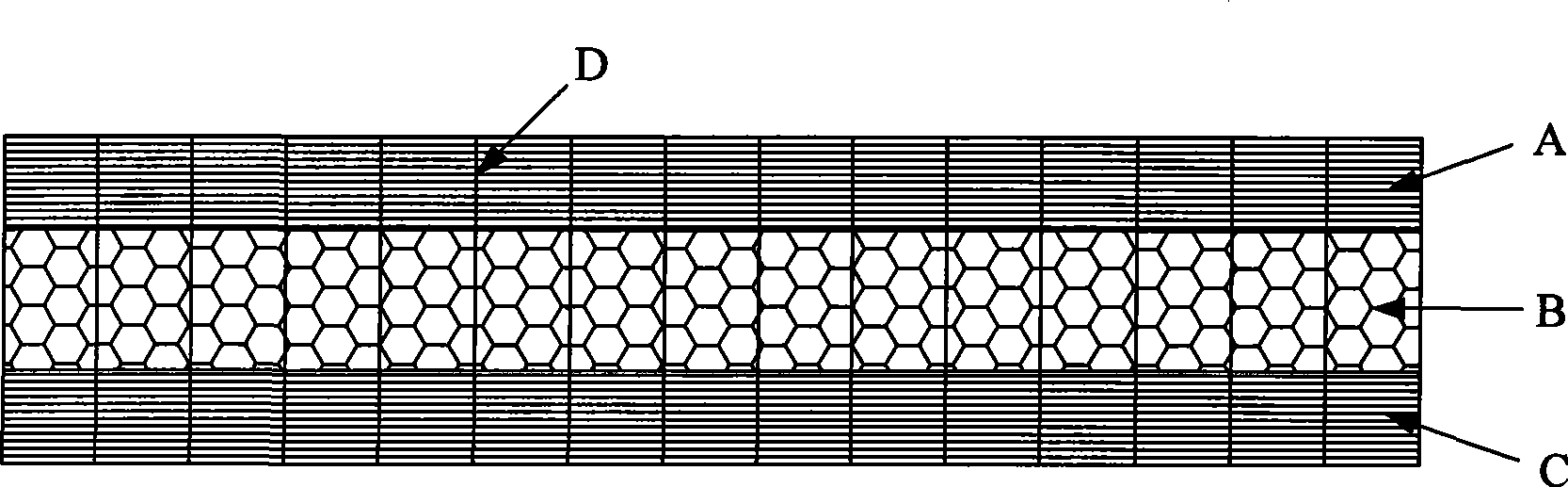

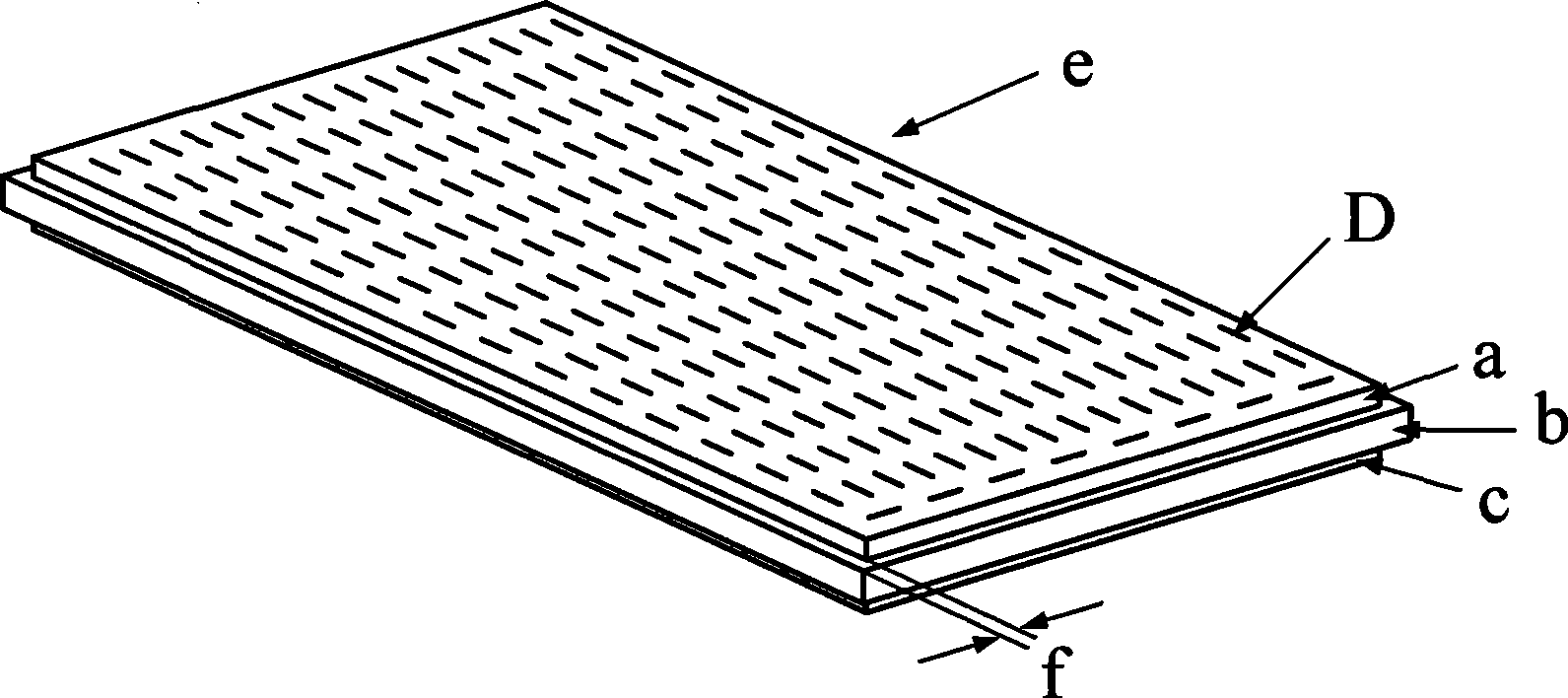

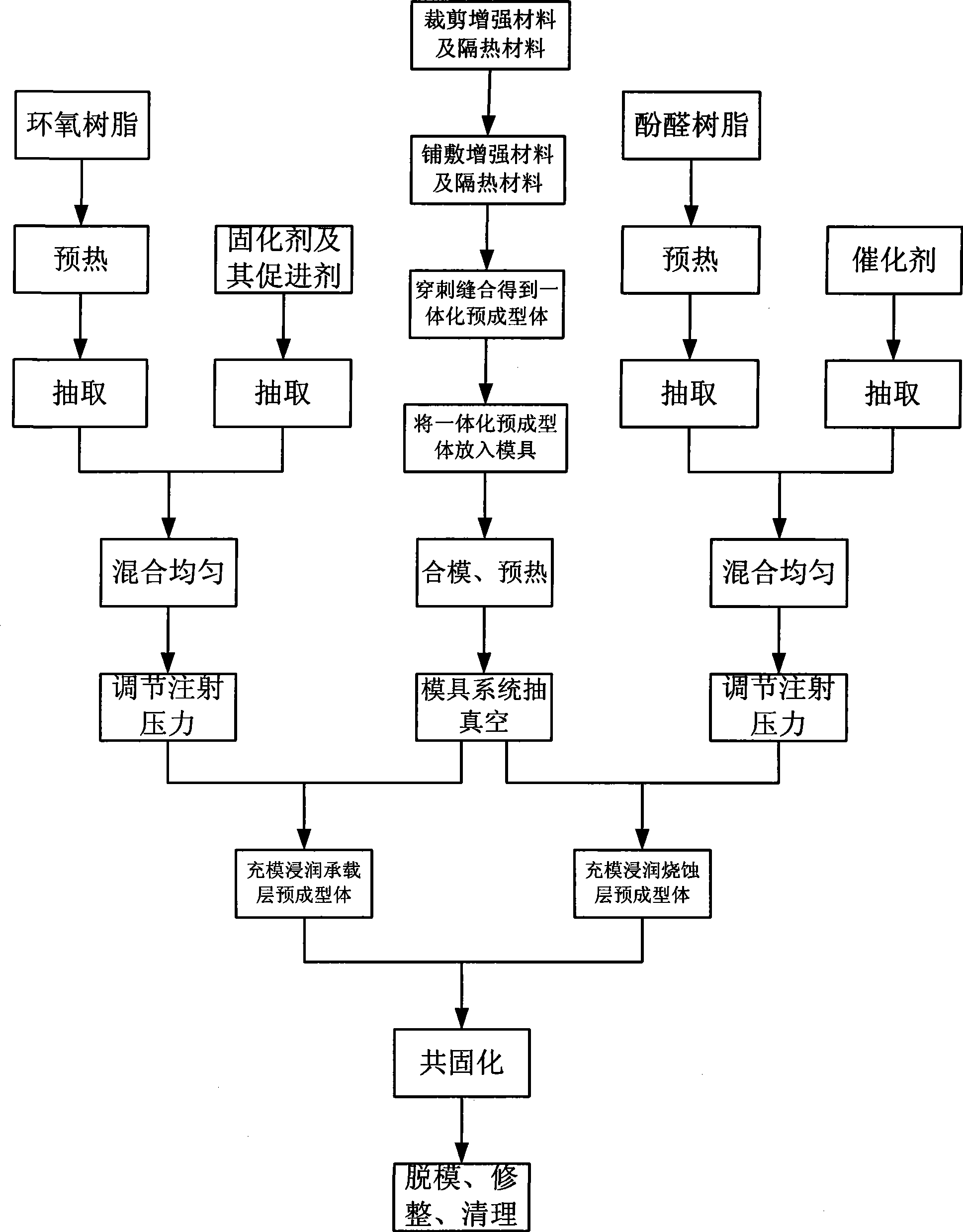

[0060] Such as image 3 , 4 Shown, the concrete processing step of preparing composite material of the present invention is as follows:

[0061] Cut out the carrier layer reinforcement c. The reinforcing material used is carbon fiber twill fabric, purchased from Toray Corporation of Japan, the brand is T300 3K, and the average surface density is 200g / m 2 , according to Figure 5 The shape and size of the male mold 25 shown in the figure cut out 10 layers of carbon fiber twill fabrics and lay them sequentially, and the fiber volume content of the reinforcing material is 45%.

[0062] Cut out the insulation material b. The heat insulation layer material used is polyetherimide foam produced by AIREX company in Switzerland, the brand is AIREX R82.80, the thermal conductivity is 0.037W / mk, and the density is 80kg / m 3 , the thickness of the foam is 20mm, and the ed...

Embodiment 2

[0079] Example 2: Application of the present invention to prepare a bearing / insulation / ablation integral composite material structure

[0080] Cut out the carrier layer reinforcement c. The reinforcing material used is carbon fiber plain weave, purchased from Japan Toray Company, the brand is T300 3K, and the average surface density is 200g / m 2 , cut 12 layers of carbon fiber cloth and lay them sequentially, and the fiber volume content of the reinforcing material is 50%.

[0081] Cut out the insulation material b. The heat insulation layer material b used is polymethacrylimide foam from Degussa Company of Germany, the grade is ROHACELL 71XT, the thickness of the foam is 25mm, and the edge of the heat insulation layer b is stronger than the corresponding ablation layer reinforcement material a and The edge of the reinforcement material c of the load-bearing layer shall be 6mm more (see figure 2 , 5 , Dimension "f" shown in 6), after cutting, pave on the reinforcement mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com