Preparation method for cylinder of nuclear magnetic resonance imager

A nuclear magnetic resonance imaging and cylinder technology, which is applied in chemical instruments and methods, medical science, lamination devices, etc., can solve the problems of unsatisfactory heat insulation and sound insulation performance, and heavy product quality, so as to facilitate the operation of workers and reduce the quality , The effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

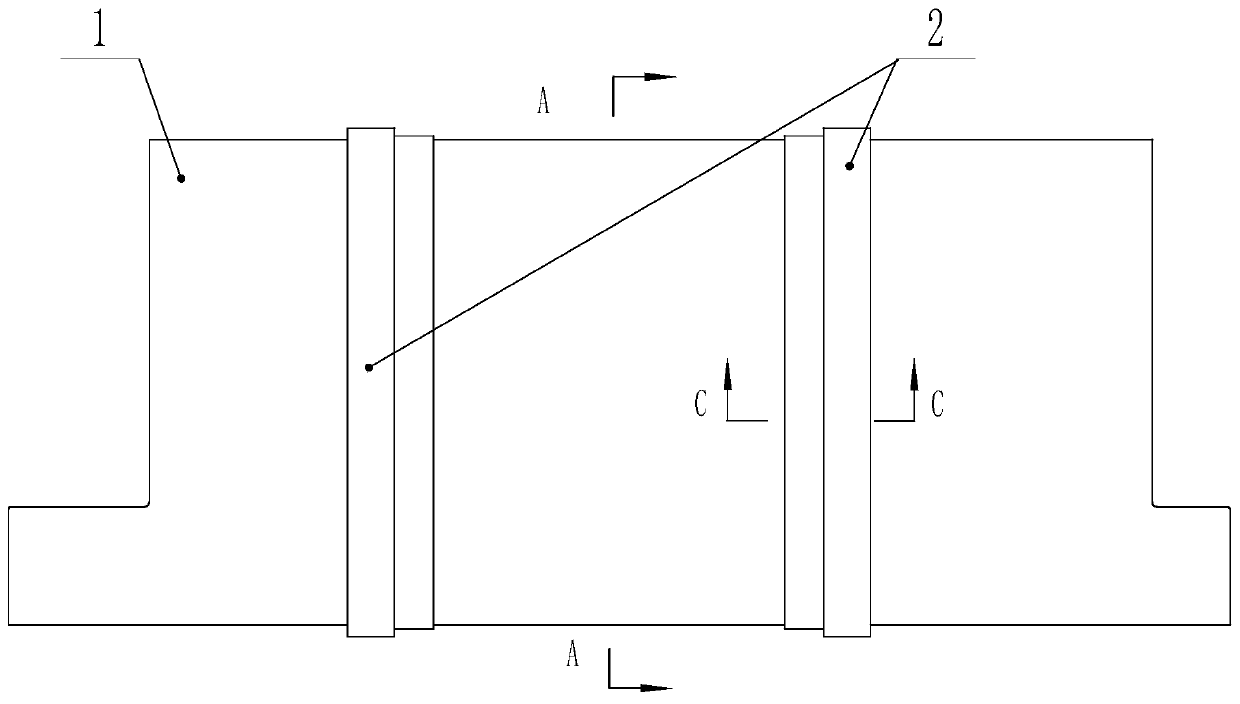

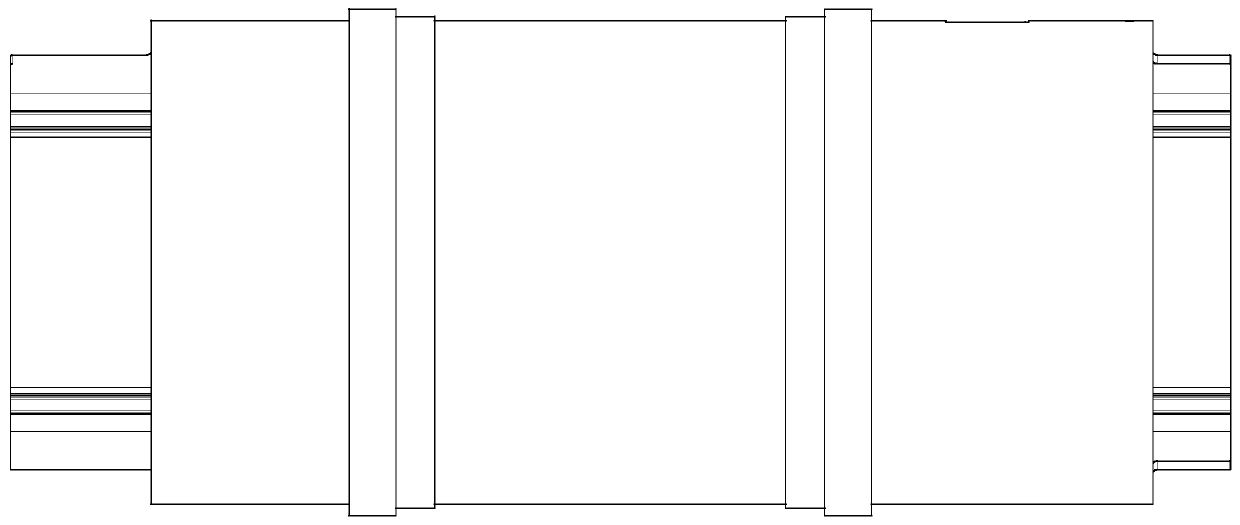

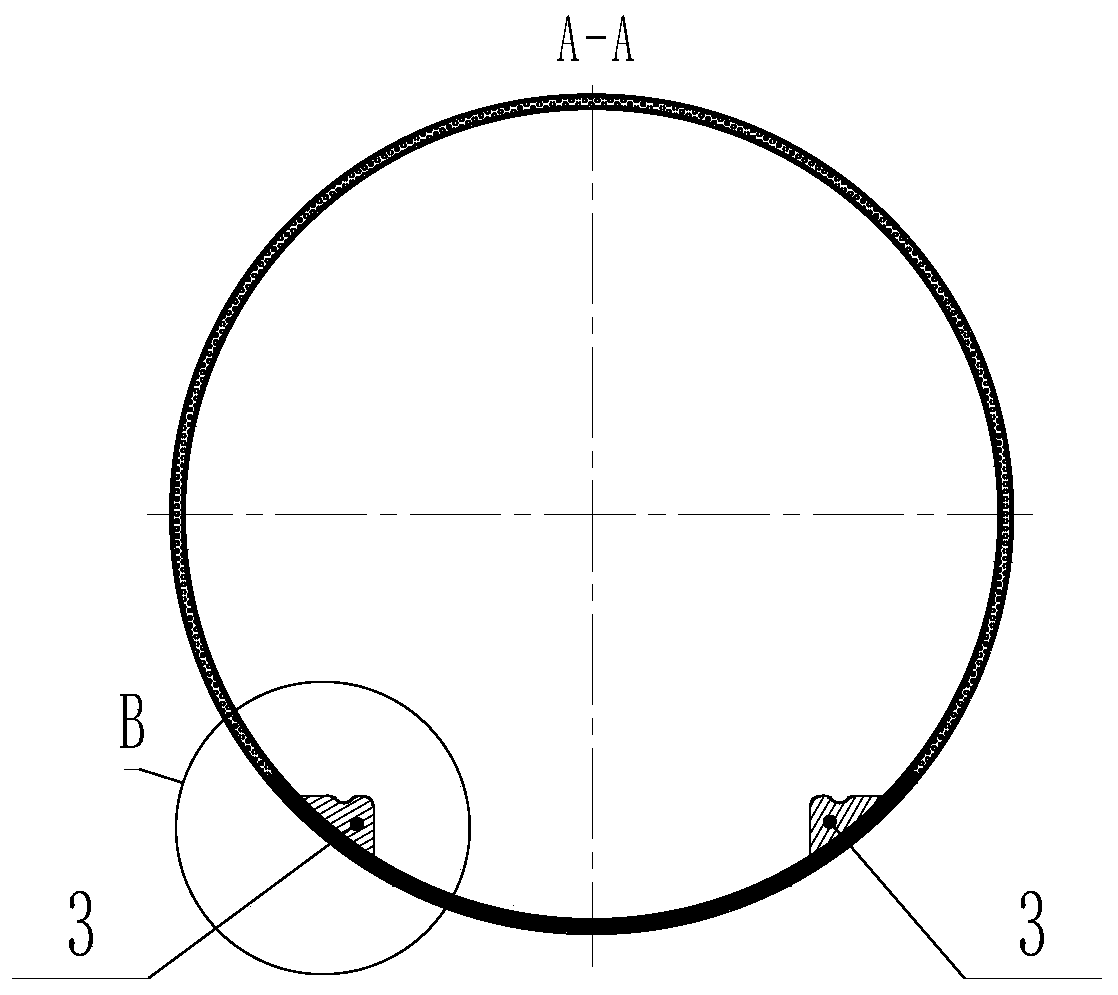

[0039] The technical solution of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

[0040] The steps of preparing the nuclear magnetic resonance imager cylinder are as follows:

[0041] Step S01: designing a metal mold and applying a release agent on the mold as required;

[0042] Step S02: laying the inner skin and vacuum compacting. The inner skin is made of 300g glass fiber woven prepreg, the thickness of a single layer of prepreg is 0.28mm, the thickness of the inner skin of the main body 1 part with a longer arc length between two solid prepreg layers 4 is 1.12mm, and the thickness of the two solid prepreg layers is 1.12mm. The inner skin thickness of the part of the main body 1 with a shorter arc length between the impregnation layers 4 is 3.08mm;

[0043] Step S03: laying the solid prepreg layer 4, the solid prepreg cloth layer is made of high modulus unidirectional glass fiber prepreg, the thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com