Prepreg with electromagnetic shielding function and preparation method thereof

A technology of electromagnetic shielding and prepreg, which is applied in the field of functional composite materials, can solve the problems of poor quality controllability of composite structural parts, uneven understanding of electromagnetic wave characteristics, and inability to give full play to the designability of composite materials. Excellent performance, high quality stability, and stable shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation method of prepreg with electromagnetic shielding function:

[0034] 1) Each component of dicyandiamide epoxy resin system, unidirectional D glass fiber yarn, toughening agent CMP-410, carbon nanotube (F-CNT), nickel mesh SN354-300 (hole distance 0.8mm) Dry at 60°C for 9 hours;

[0035] 2) Mix each component of the dicyandiamide epoxy resin system in step 1) uniformly, heat to a molten state, and mix uniformly with CMP-410 and carbon nanotubes (F-CNT) to obtain a prepreg resin mixture;

[0036] 3) the unidirectional D glass fiber yarn of step 1) is regularly arranged on the yarn guide system of the prepreg machine;

[0037] 4) Apply the unidirectional D glass fiber yarn of step 3) to both sides of the nickel mesh in step 1), to obtain a reinforcing material mixture;

[0038] 5) The prepreg resin mixture in step 2) is combined with the upper and lower sides of the reinforcing material mixture obtained in step 4) through a one-step hot-melt prepreg machine to...

Embodiment 2

[0043] 1) Dry cyanate resin, T800 carbon fiber yarn, toughening agent SA-2000, carbon nanotube (F-CNT), and carbon nanotube film (0.5 mm in thickness) in an atmosphere at 100 ° C for 2 hours;

[0044] 2) heating the cyanate resin in step 1) to a molten state, and mixing it with the toughening agent SA-2000 and carbon nanotubes (F-CNT) to obtain a prepreg resin mixture;

[0045] 3) regularly arrange the T800 carbon fibers in step 1) on the yarn guide system of the prepreg machine;

[0046] 4) Paste the T800 carbon fiber of step 3) on both sides of the carbon nanotube film of step 1) to obtain a reinforcing material mixture;

[0047] 5) Combine the prepreg resin mixture in step 2) on both sides of the reinforcing material mixture obtained in step 4) through a one-step hot-melt prepreg machine to obtain an electromagnetic shielding prepreg. The prepreg temperature is 100°C, and the hot-melt pressure is 2 MPa;

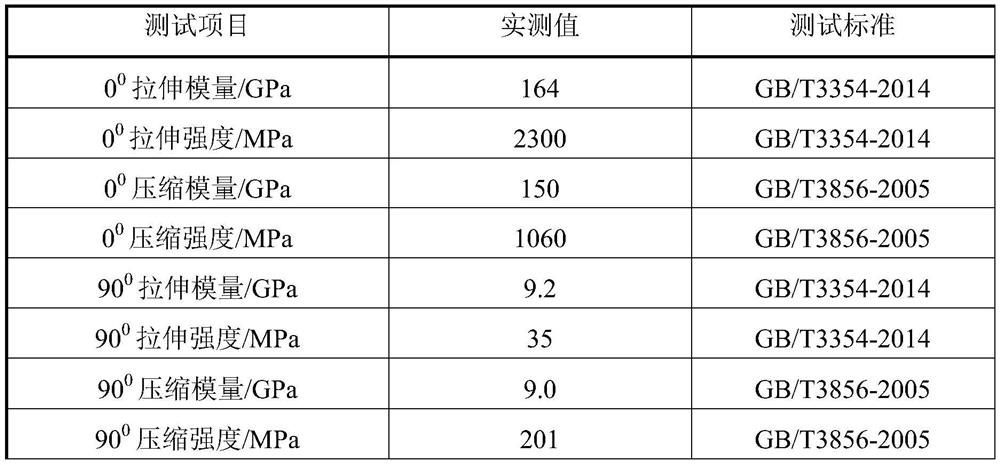

[0048] Composite material prepreg performance test results:

[004...

Embodiment 3

[0055] 1) Dry Shuangma resin, T700 carbon fiber 3K plain weave cloth, toughening agent SA-2000, aminated graphene XF005-4, and carbon nanotube film (thickness 0.5 mm) in an atmosphere of 900 ° C for 5 hours;

[0056] 2) heating the double horse resin resin in step 1) to a molten state, and mixing it with the toughening agent SA-2000 and aminated graphene to obtain a prepreg resin mixture;

[0057] 3) regularly arrange the T700 carbon fiber cloth of step 1) on the yarn guide system of the prepreg machine;

[0058] 4) Applying the two sides of the carbon nanotube film in step 1) to the two sides of the T700 carbon fiber cloth in step 3), to obtain a reinforcing material mixture;

[0059] 5) Compounding the prepreg resin mixture in step 2) on both sides of the reinforcing material mixture obtained in step 4) through a one-step hot-melt prepreg machine to obtain an electromagnetic shielding prepreg. Prepreg temperature 120°C, hot melt pressure 1MPa

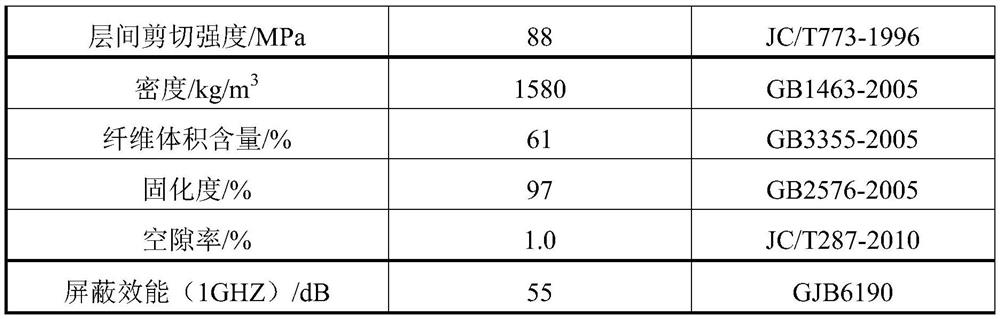

[0060] Prepreg performance t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com