Chemical vapor deposition method of Si-B-C-N amorphous ceramic

A chemical vapor deposition, si-b-c-n technology, applied in the field of chemical vapor deposition, can solve the problems of no ceramic matrix composite material interface and substrate reports, etc., and achieve the effect of easy preparation of large size, good uniformity and strong designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

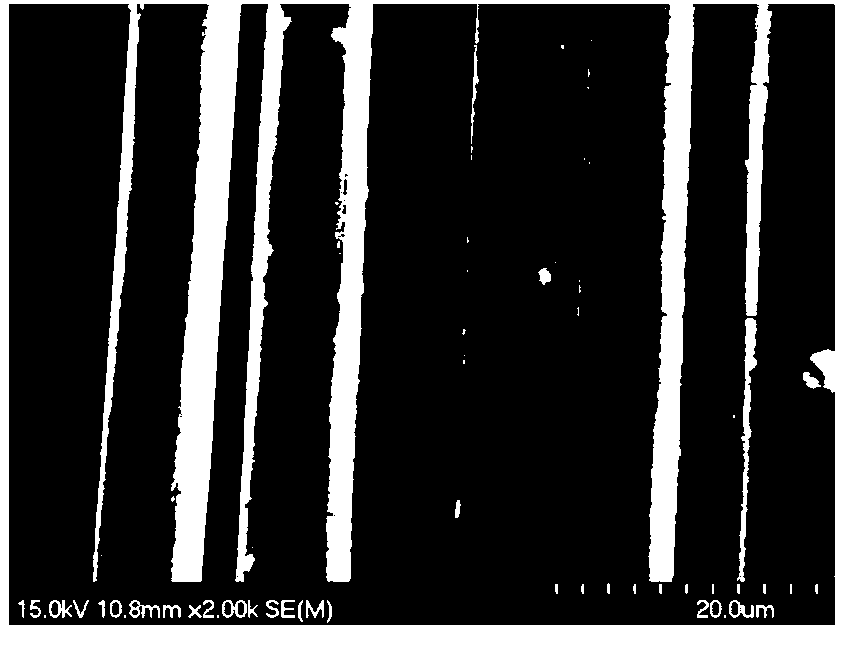

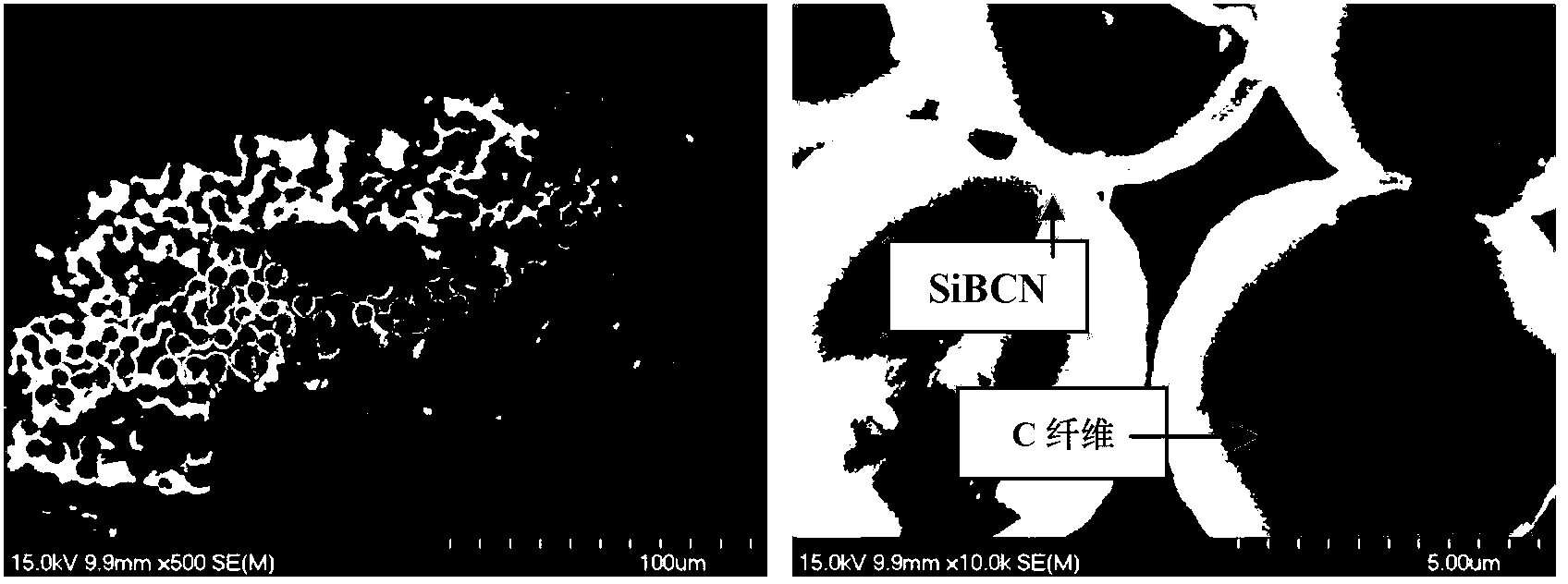

[0027] (1) Use 2-dimensional plain carbon cloth with brand T300 as the base, and cut it to a size of 50mm×50mm;

[0028] (2) Hang the above base material on the supporting sample holder of the vacuum furnace, and the sample is in the center of the isothermal zone in the furnace;

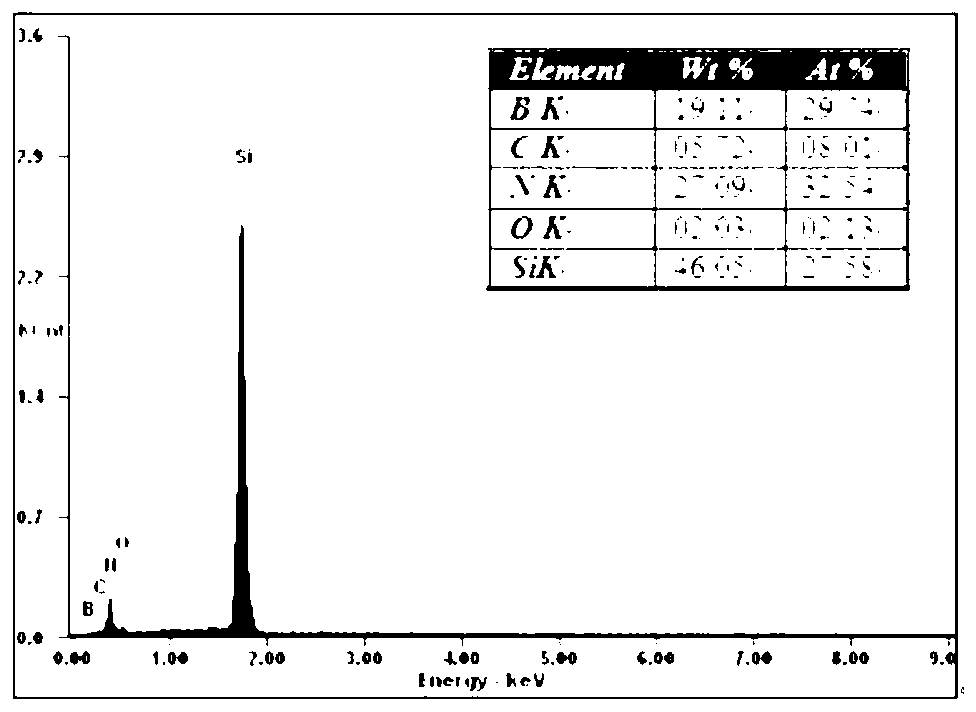

[0029] (3) Prepare Si-B-C-N ceramics with uniform thickness on the substrate by CVD / CVI method, the precursor is SiCH 3 Cl 3 -BCl 3 -NH 3 -H 2 -Ar,H 2 Carrier gas and NH 3 The flow ratio is 2:3, BCl 3 : NH 3 : dilute H 2 : Ar=1:3:5:5. Reaction temperature is 900 DEG C, and soaking time is 7 hours, and pressure in furnace is 1000Pa.

Embodiment 2

[0031] (1) Select porous Si 3 N 4 The ceramic substrate is pre-processed according to the size of 22.86mm × 10.16mm × 2.2mm, and the surface of the formed substrate is ground and polished as the base material;

[0032] (2) Hang the above base material on the supporting sample holder of the vacuum furnace, and the sample is in the center of the isothermal zone in the furnace;

[0033] (3) Prepare Si-B-C-N ceramics with uniform thickness on the substrate by CVD / CVI method, the precursor is SiCl 4 -BCl 3 -C 3 h 6 -NH 3 -H 2 -Ar,H 2 Carrier gas and NH 3 The flow ratio is 1:1, BCl 3 :C 3 h 6 : NH 3 : dilute H 2 : Ar=1:1:4:5:10, the reaction temperature is 700°C, the holding time is 7 hours, and the pressure in the furnace is 400Pa;

[0034] Si 3 N 4 -SiBCN composite phase ceramics are tested for dielectric properties, and the test frequency is 8.2-12.4GHz.

Embodiment 3

[0036] (1) Select porous Si 3 N 4 The ceramic substrate is pre-processed according to the size of 22.86mm × 10.16mm × 2.2mm, and the surface of the formed substrate is ground and polished as the base material;

[0037] (2) Hang the above base material on the supporting sample holder of the vacuum furnace, and the sample is in the center of the isothermal zone in the furnace;

[0038] (3) Prepare Si-B-C-N ceramics with uniform thickness on the substrate by CVD / CVI method, the precursor is SiCl 4 -BCl 3 -CH 4 -NH 3 -H 2 -Ar,H 2 Carrier gas and NH 3 The flow ratio is 1:1, BCl 3 :CH 4 : NH 3 : dilute H 2 : Ar=1:3:4:6:6, the reaction temperature is 1200°C, the holding time is 7 hours, and the pressure in the furnace is 500Pa;

[0039] Si 3 N 4 -SiBCN composite phase ceramics are tested for dielectric properties, and the test frequency is 8.2-12.4GHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com