Dual-membrane-rack high-speed cantilever type winding machine

A cantilever type and winding machine technology, which is applied in the direction of packaging/bundling items, packaging, and web rotary wrapping, etc., can solve the problems of slow packaging speed and low efficiency, and achieve improved production efficiency, accurate positioning, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

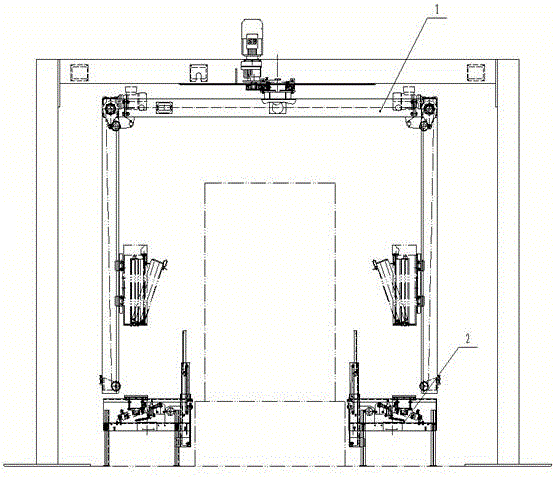

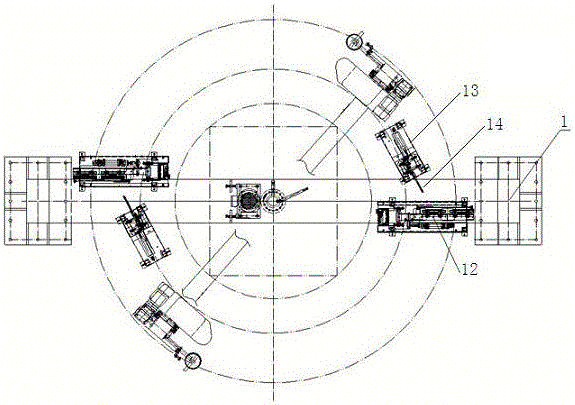

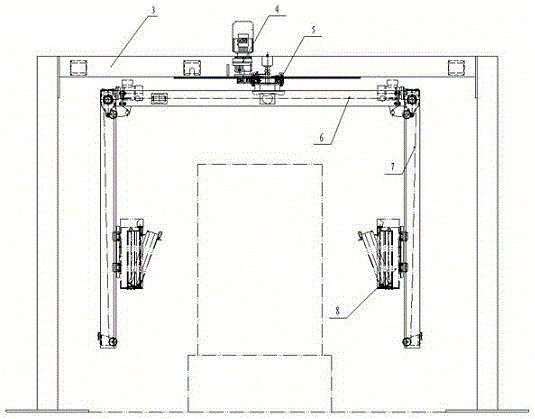

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] Accompanying drawing is a kind of specific embodiment of the present invention. like figure 1 , 2 , 3, and 4, this embodiment includes a cantilever on-line winding main machine 1 and an automatic film breaking mechanism 2. The cantilever on-line winding main machine includes a mounting frame 3, and the mounting frame is installed through a slewing bearing 5. The rocker arm 6 is provided with a rocker reduction motor 4 on the mounting frame, and the rocker reduction motor drives the rocker to rotate around the rotation support through the gear meshing with the slewing support. Respectively be provided with vertical lifting frame 7, described lifting frame is provided with film frame 8 that can move up and down along the lifting frame, and described lifting frame is also provided with a driving device that drives the film frame to move up and down; There are tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com