Preparation method for glass fibre reinforced resin composite plate spring

A composite material plate and reinforced resin technology, applied in the field of composite material leaf springs, can solve problems such as increased manufacturing costs, product size limitations, and lack of glue in trachoma, and achieve the effects of improving production efficiency, improving comprehensive performance, and accurate data monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

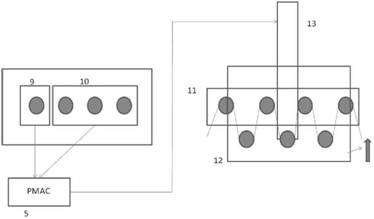

Method used

Image

Examples

Embodiment 1

[0076] The epoxy fiber composition used for impregnation is prepared, containing in parts by weight: 100 parts of bisphenol A epoxy resin, 30 parts of TMA, 10 parts of polysulfide toughening agent, 5 parts of diluent XY6695 parts, and 0.5 part of KH560.

[0077] Fully impregnate the glass fiber cloth and glass fiber filaments in the epoxy resin composition, lay a layer of the glass fiber cloth impregnated with epoxy resin on the surface of the upper and lower mandrels of the double mandrel, and then start layer by layer at the same time The glass fiber cloth impregnated with epoxy resin and 18 glass fiber filaments are wound side by side.

[0078]Before laying, a tension of 50N per single yarn is applied to the glass fiber filaments. As the number of winding layers increases, the tension applied to the glass fiber filaments decreases at a rate of 5N / layer, and the total number of winding layers is 8 layers.

[0079] After the 8 layers are completed, continue to wind a layer of...

Embodiment 2

[0082] The epoxy fiber composition used for impregnation is prepared, containing in parts by weight: 100 parts of bisphenol F epoxy resin, 30 parts of PAPA, 35 parts of polyether resin toughening agent, 25 parts of diluent XY73225 parts, and 0.8 parts of KH7920.8 parts.

[0083] Fully impregnate glass fiber cloth and glass fiber filaments in the above epoxy resin composition, lay a layer of glass fiber cloth impregnated with epoxy resin on the surface of the upper and lower mandrels of the four-piece mandrel, and then start layer by layer at the same time. The glass fiber cloth impregnated with epoxy resin and 20 glass fiber filaments are wound in parallel.

[0084] Before laying, a tension of 100N per single yarn is applied to the glass fiber filaments. As the number of winding layers increases, the tension applied to the glass fiber filaments decreases at a rate of 5N / layer, and the total number of winding layers is 20 layers.

[0085] After the 20 layers of winding are comp...

Embodiment 3

[0089] Prepare an epoxy fiber composition for impregnation, containing in parts by weight: 100 parts of hydrogenated bisphenol A type epoxy resin, 32 parts of polyamide curing agent, 15 parts of polyether resin toughening agent, 10 parts of thinner XY66910 parts, DL602 0.7 parts of silane coupling agent.

[0090] Fully impregnate glass fiber cloth and glass fiber filaments in the above epoxy resin composition, lay a layer of glass fiber cloth impregnated with epoxy resin on the surface of the upper and lower mandrels of the three-piece mandrel, and then start layer by layer at the same time The glass fiber cloth impregnated with epoxy resin and 24 glass fiber filaments are wound in parallel.

[0091] Before laying, a tension of 80N per single yarn is applied to the glass fiber filaments. As the number of winding layers increases, the tension applied to the glass fiber filaments decreases at a rate of 8N / layer, and the total number of winding layers is 10 layers.

[0092] Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com