Patents

Literature

113 results about "Fiberglass reinforced resins" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

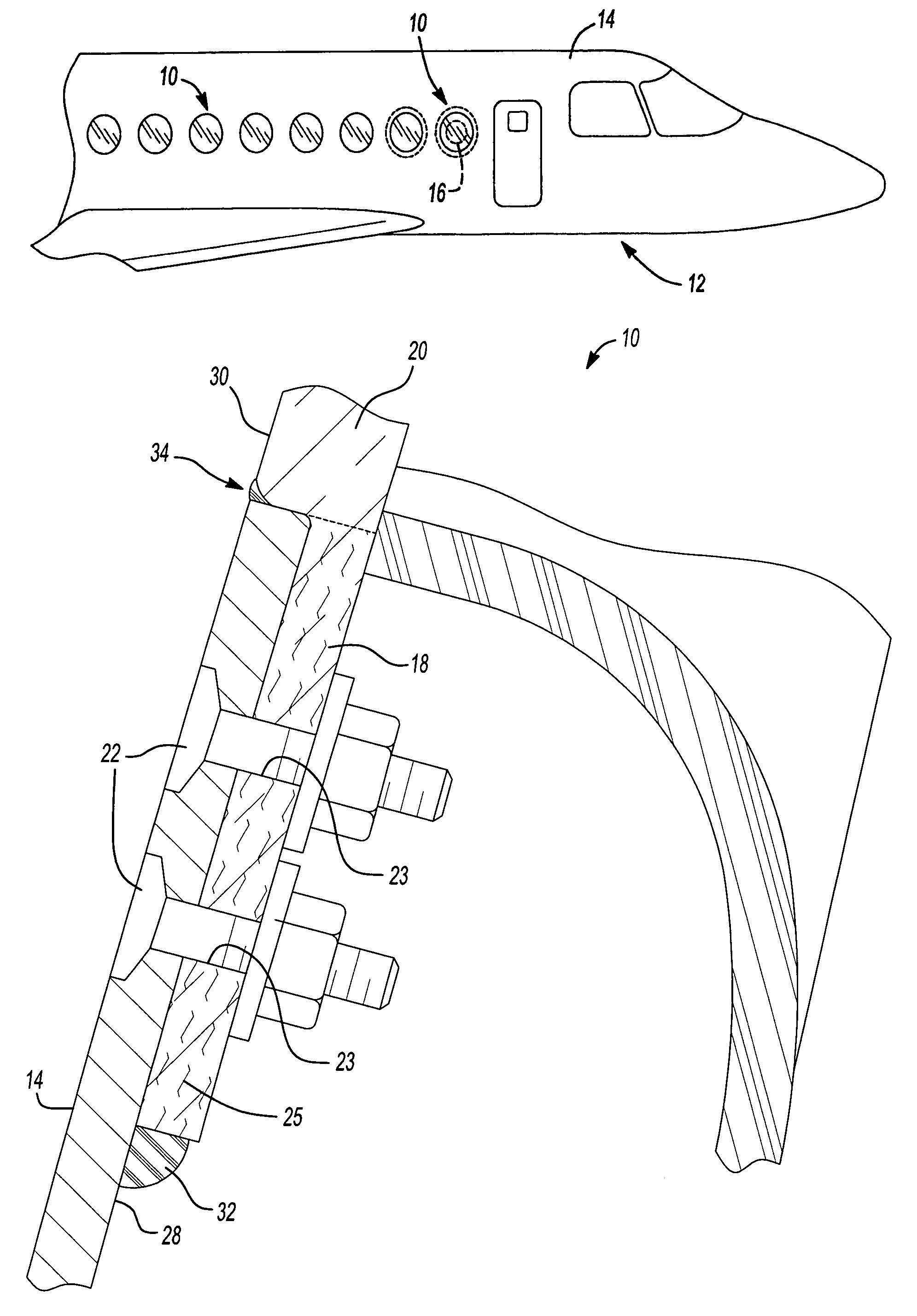

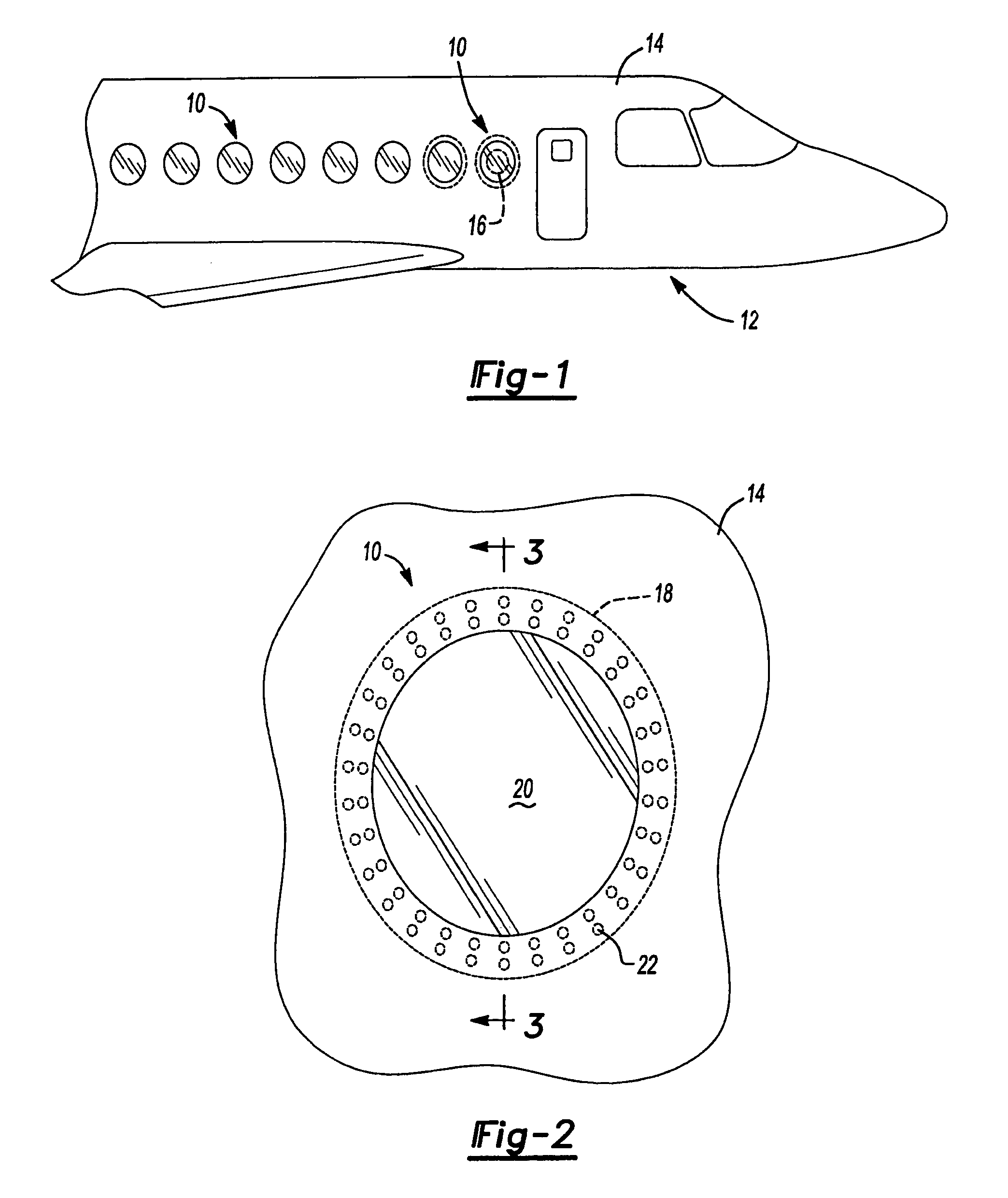

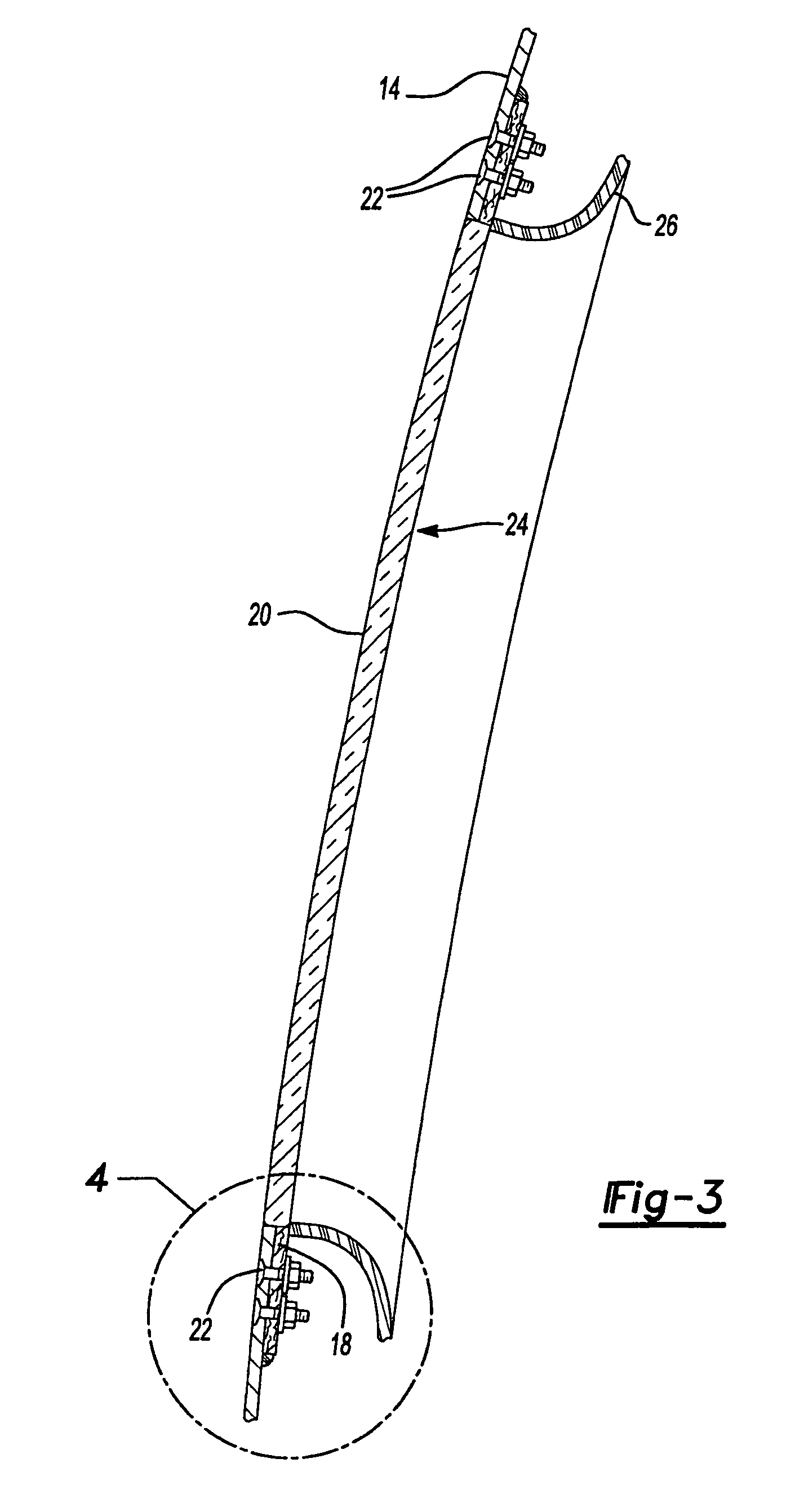

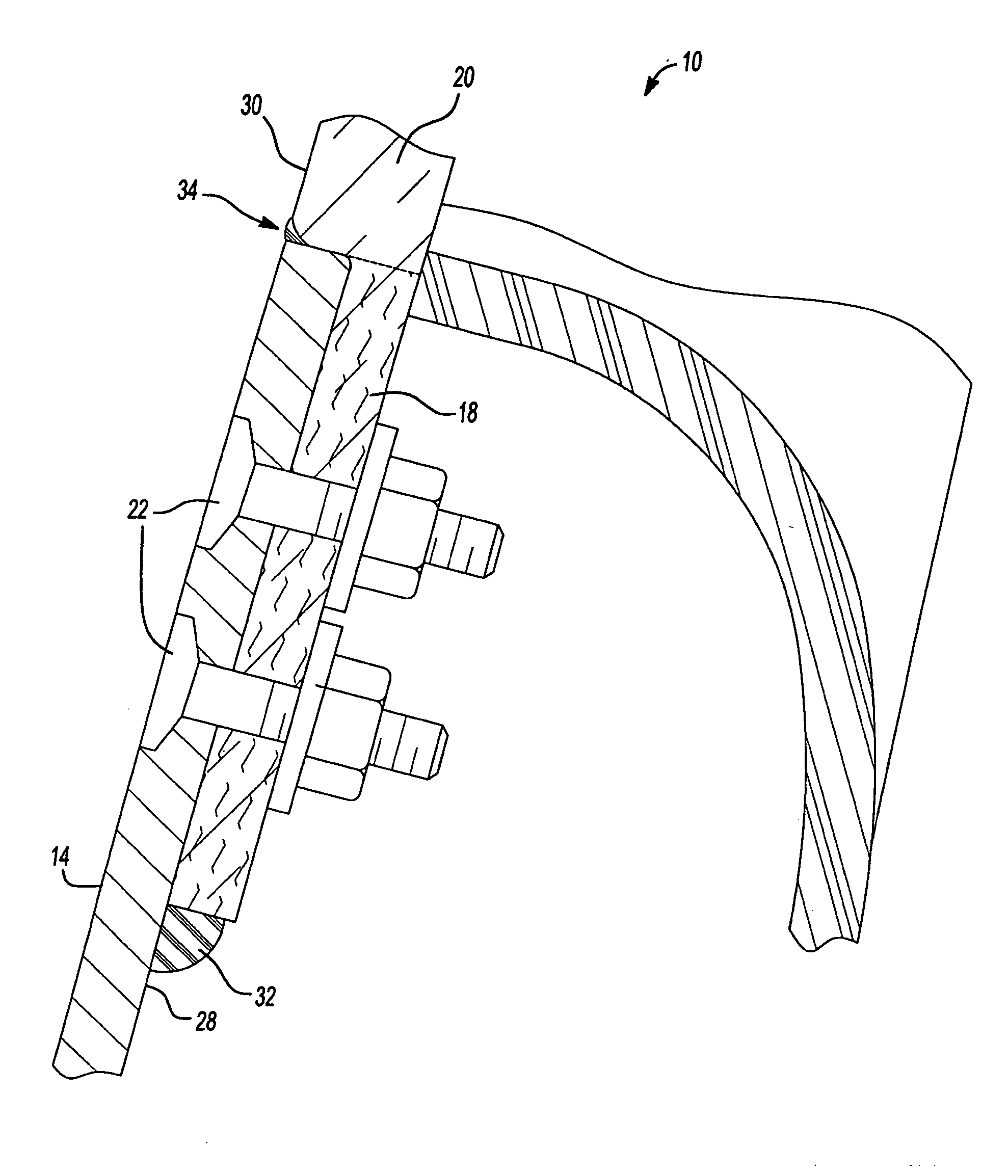

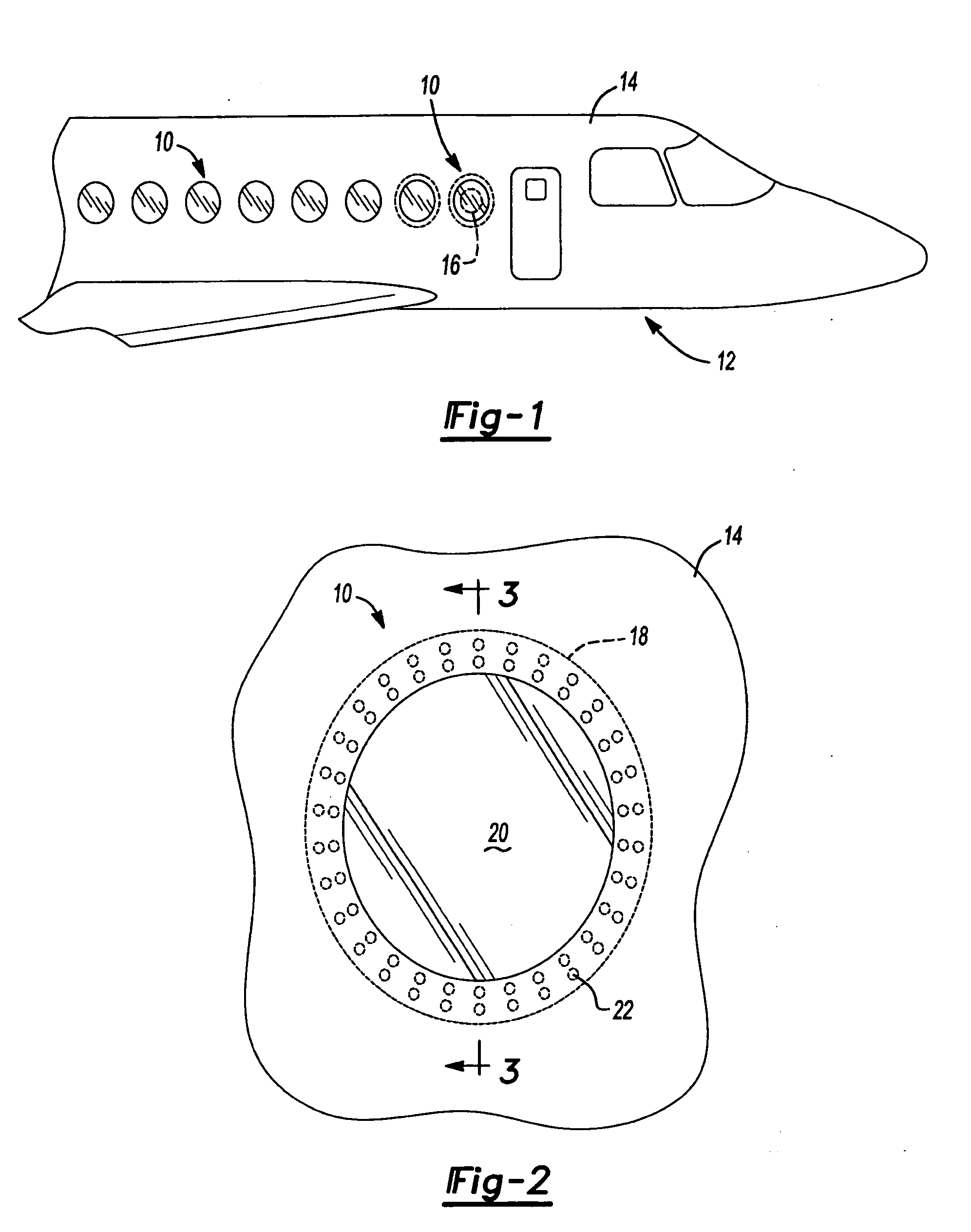

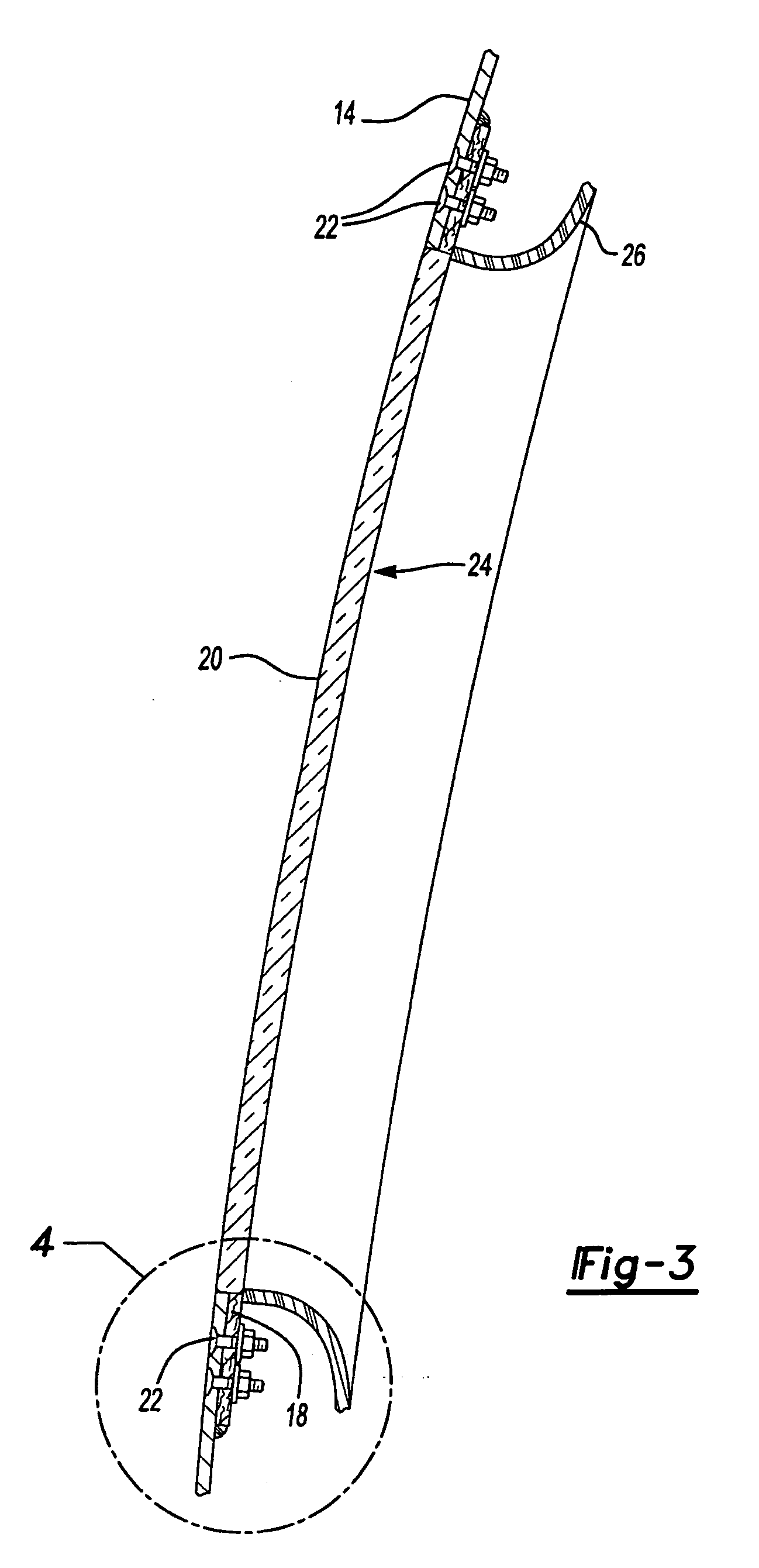

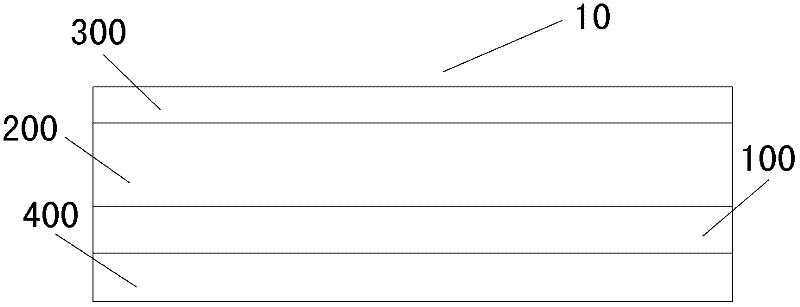

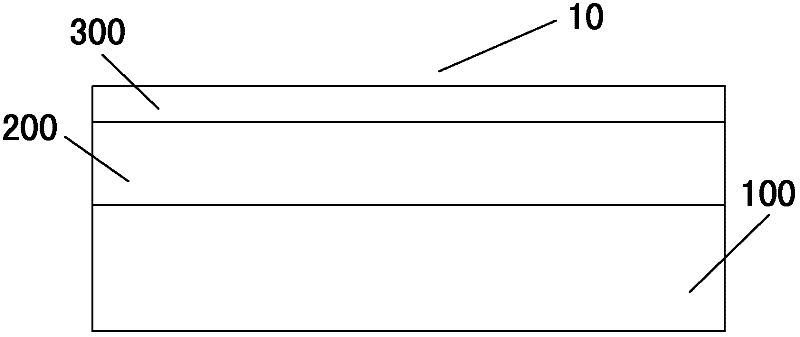

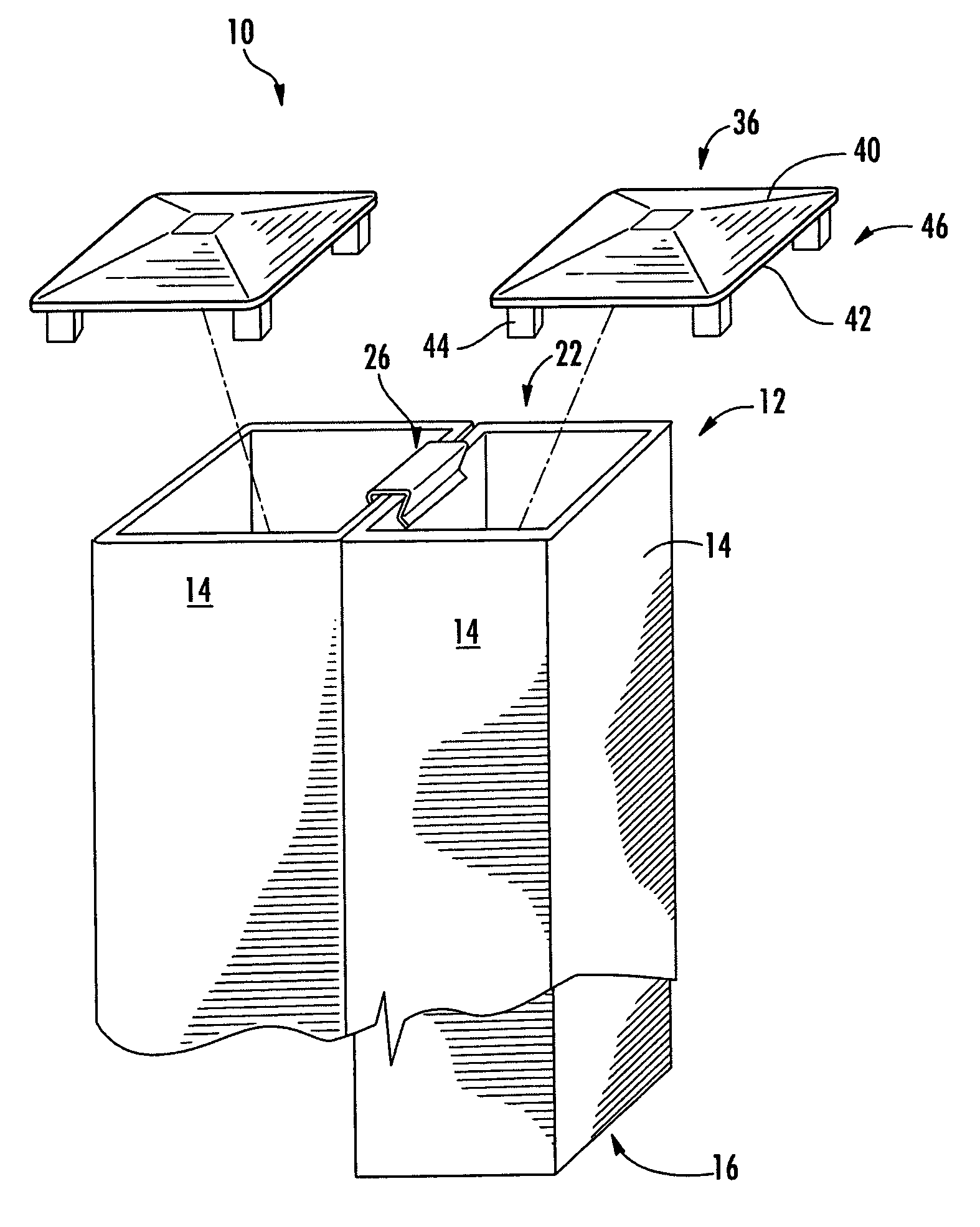

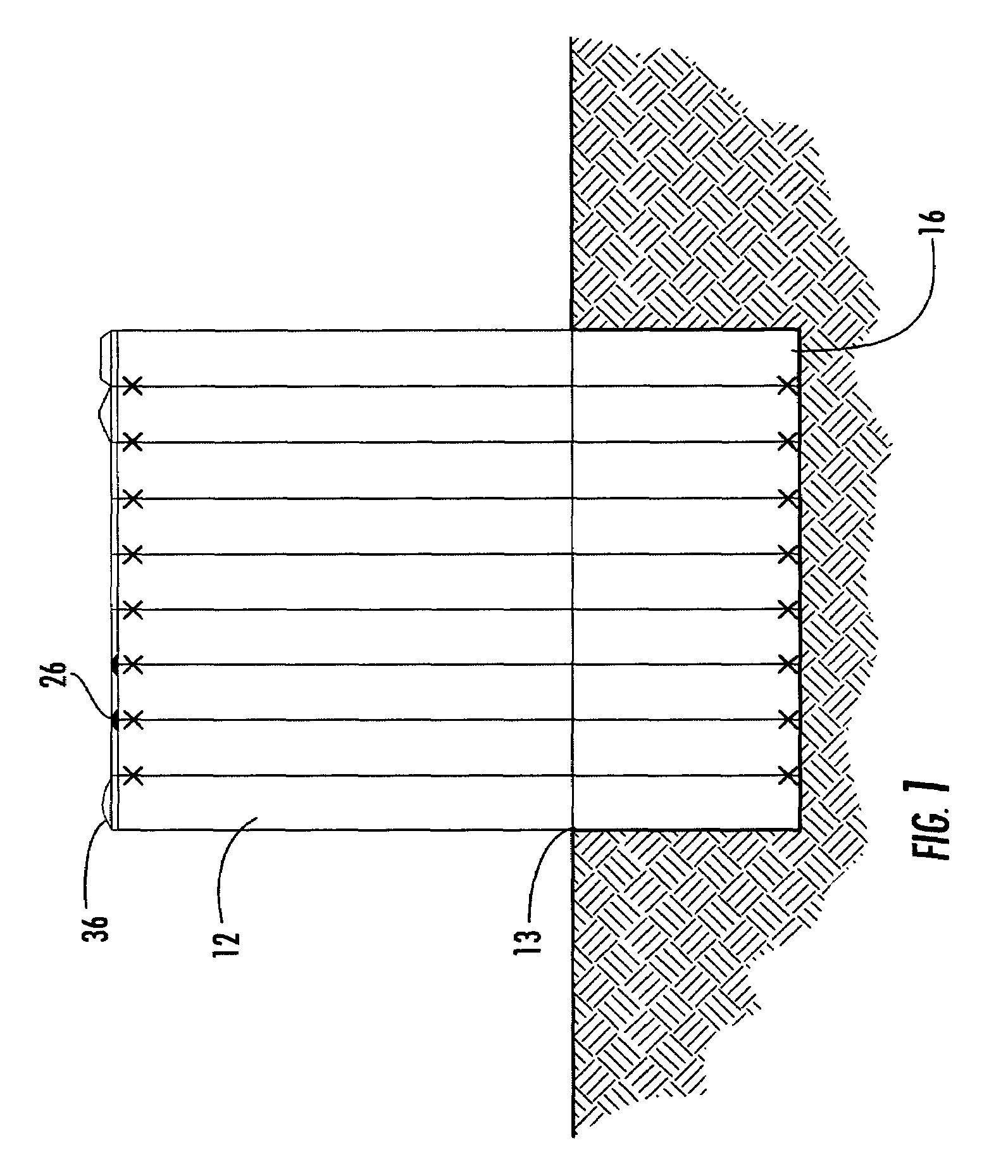

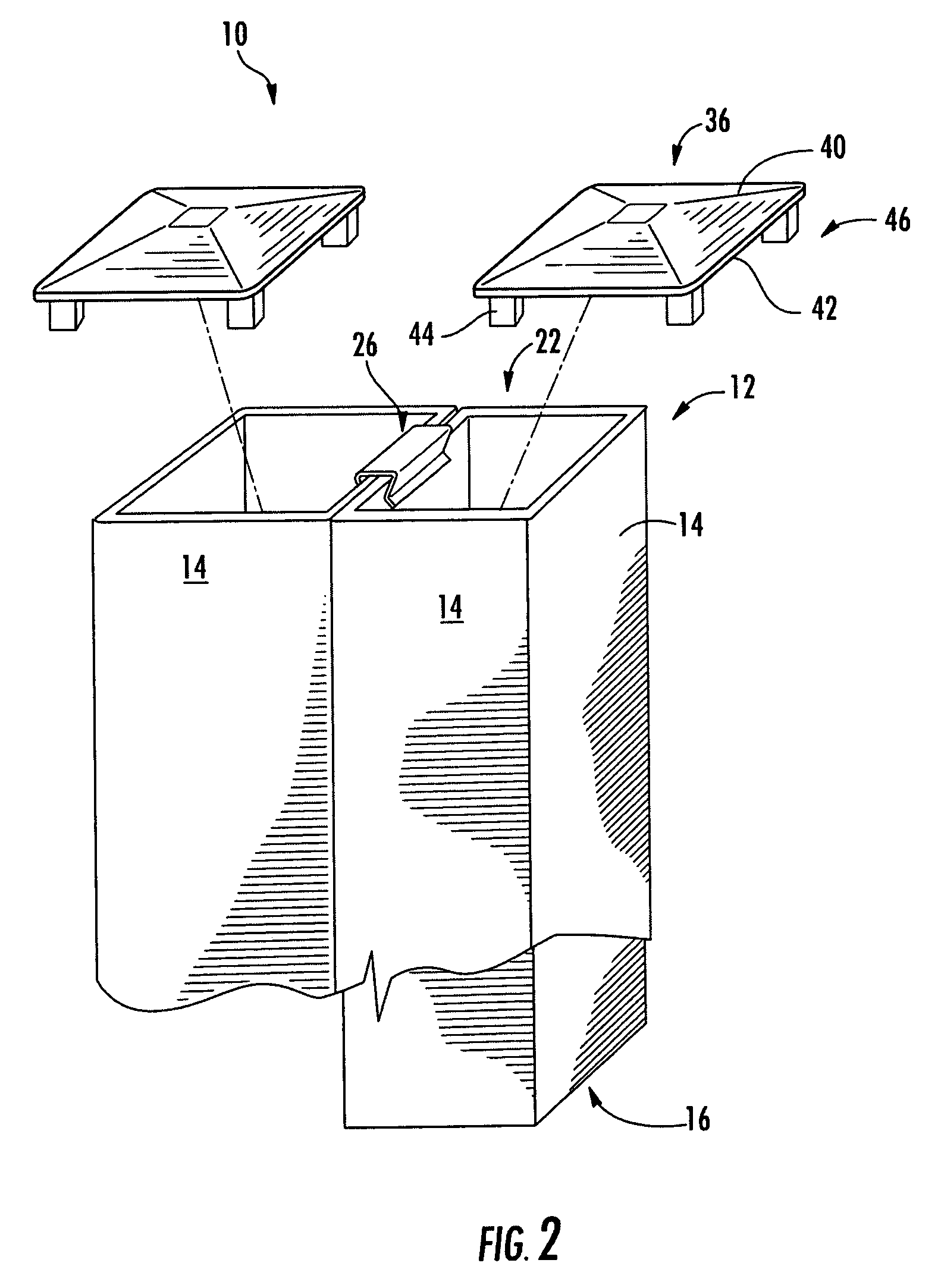

Load bearing window

A substantially strong, lightweight load bearing window for use in a mobile platform, for example, an aircraft. The window includes a rim portion having a carbon reinforced resin structure and a transparent portion having a fiberglass reinforced resin structure. A plurality of holes are formed in the rim portion for enabling a plurality of connectors to be inserted therethrough. The rim portion has a smaller cross sectional area (i.e., thickness) than the transparent portion such that the rim portion is adapted to fit behind a skin of an aircraft, the transparent portion is adapted to be flush with the skin of the aircraft. The connectors fix the window to the skin of the aircraft. The window effectively forms a strong, structurally integral portion of the skin.

Owner:THE BOEING CO

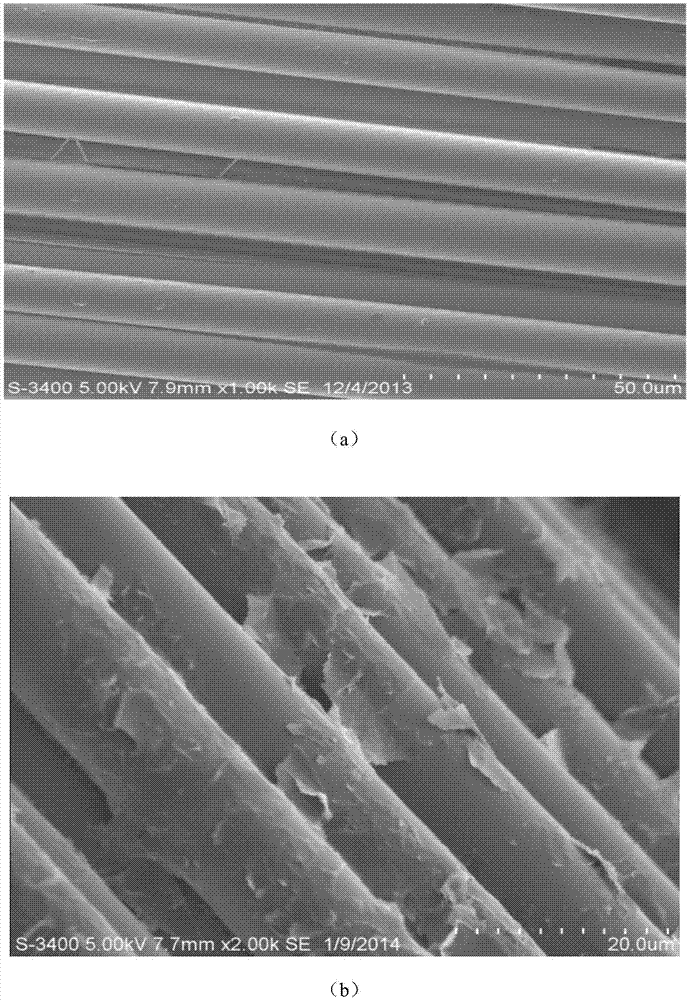

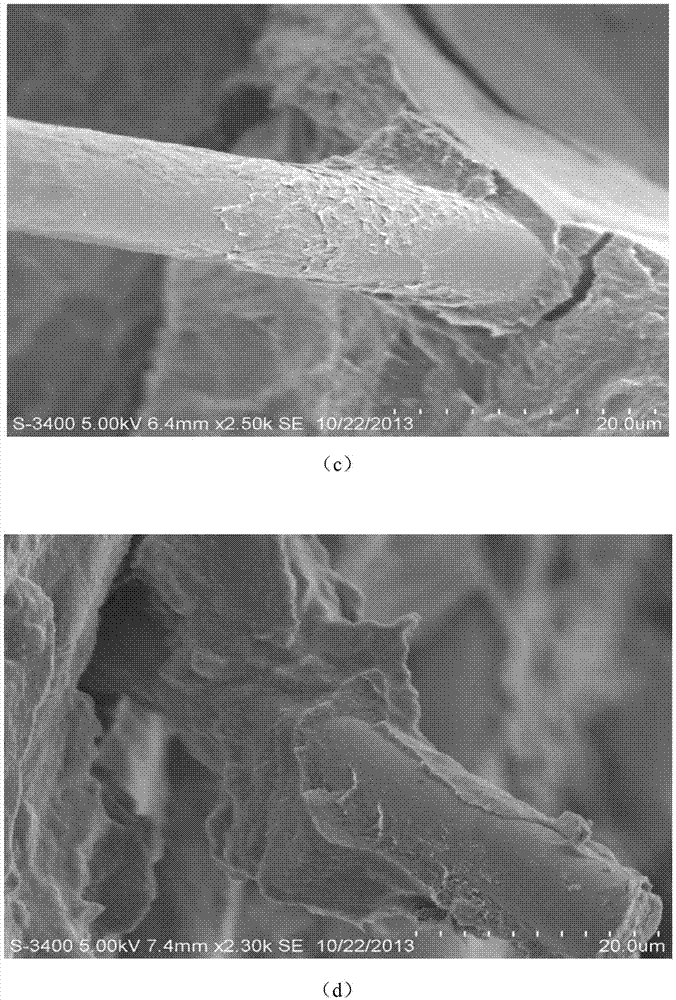

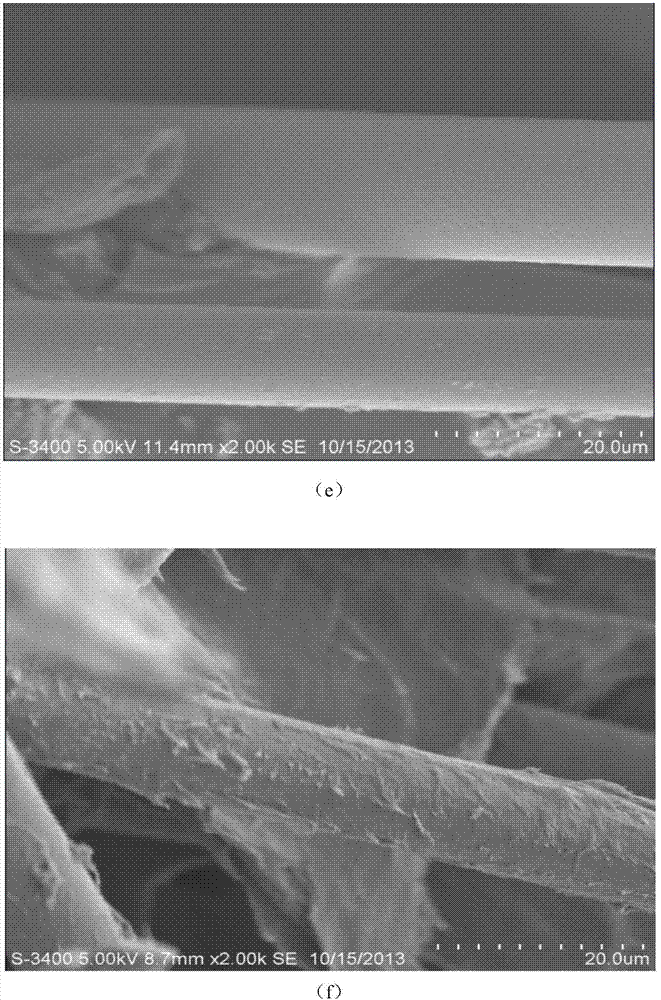

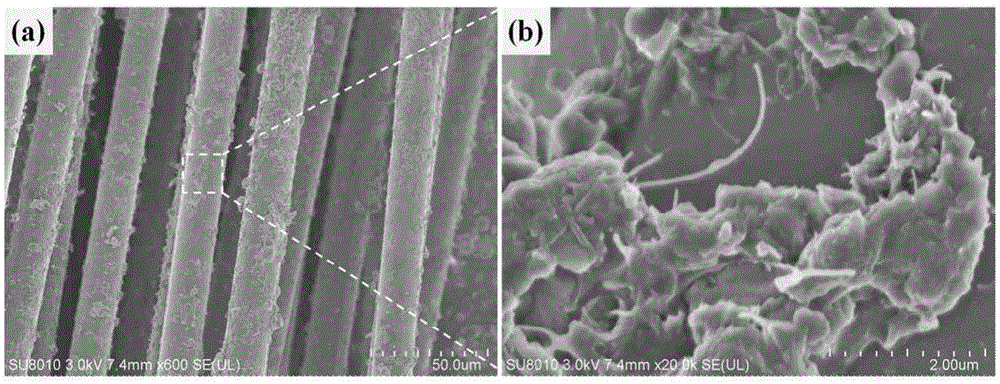

Graphene-coated glass fiber reinforced resin-based composite material and preparation method thereof

ActiveCN104262953ASolve the problem of fragmentationImprove bending strengthGlass fiberGraphene coating

The invention provides a graphene-coated glass fiber reinforced resin-based composite material. The preparation method comprises the following steps of dispersing graphene modified by a silane coupling agent in water to obtain a uniformly-dispersed aqueous dispersion, dipping glass fibers into the aqueous dispersion of the modified graphene so that compact and uniform graphene coatings are formed on surfaces of the glass fibers under the action of electrostatic adsorption, and carrying out compounding molding on the glass fibers with the graphene coatings and a resin matrix to obtain a composite material. The graphene coatings are arranged on the surfaces of the glass fibers so that the interaction area and interface bonding strength of the fibers and the matrix are improved, graphene dispersion is avoided and excellent composite material mechanical properties are obtained. The preparation method has simple processes, a low cost and good practicality.

Owner:JUSHI GRP CO

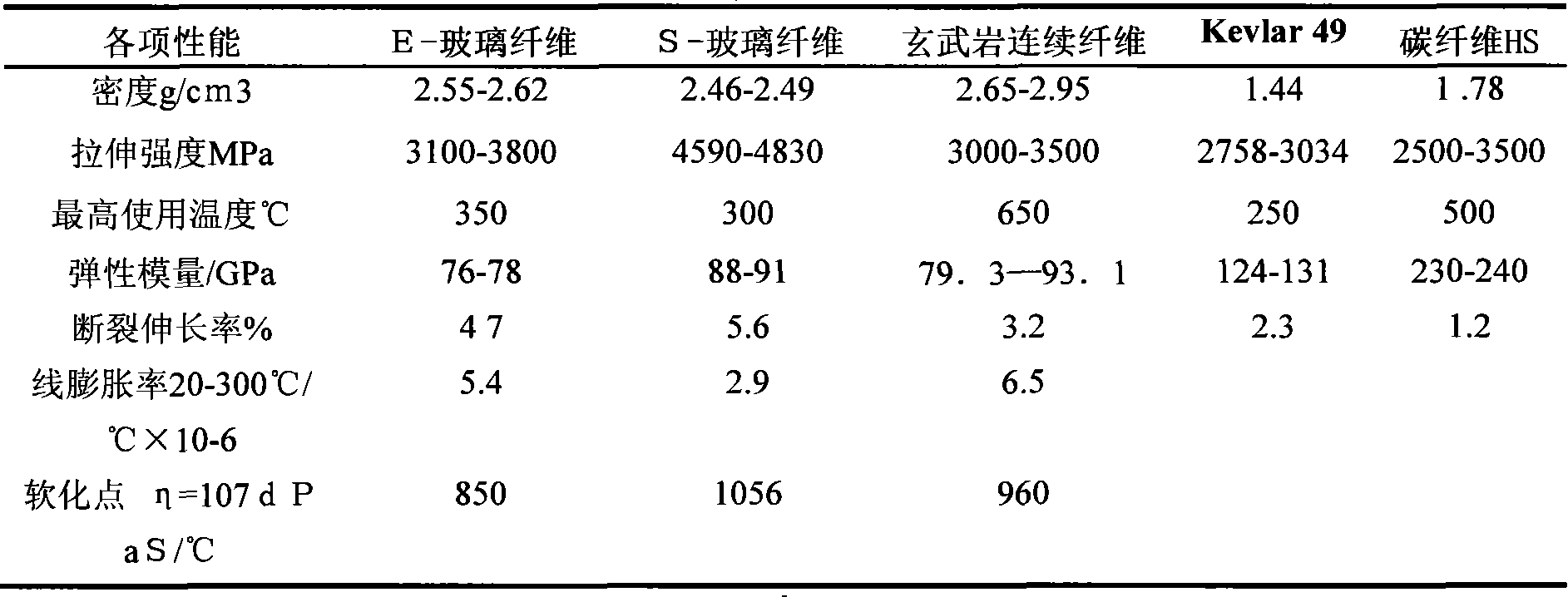

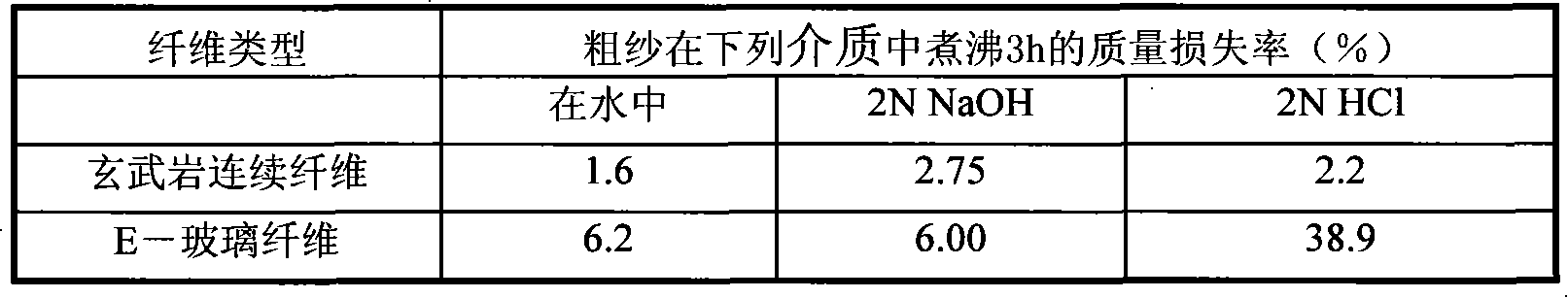

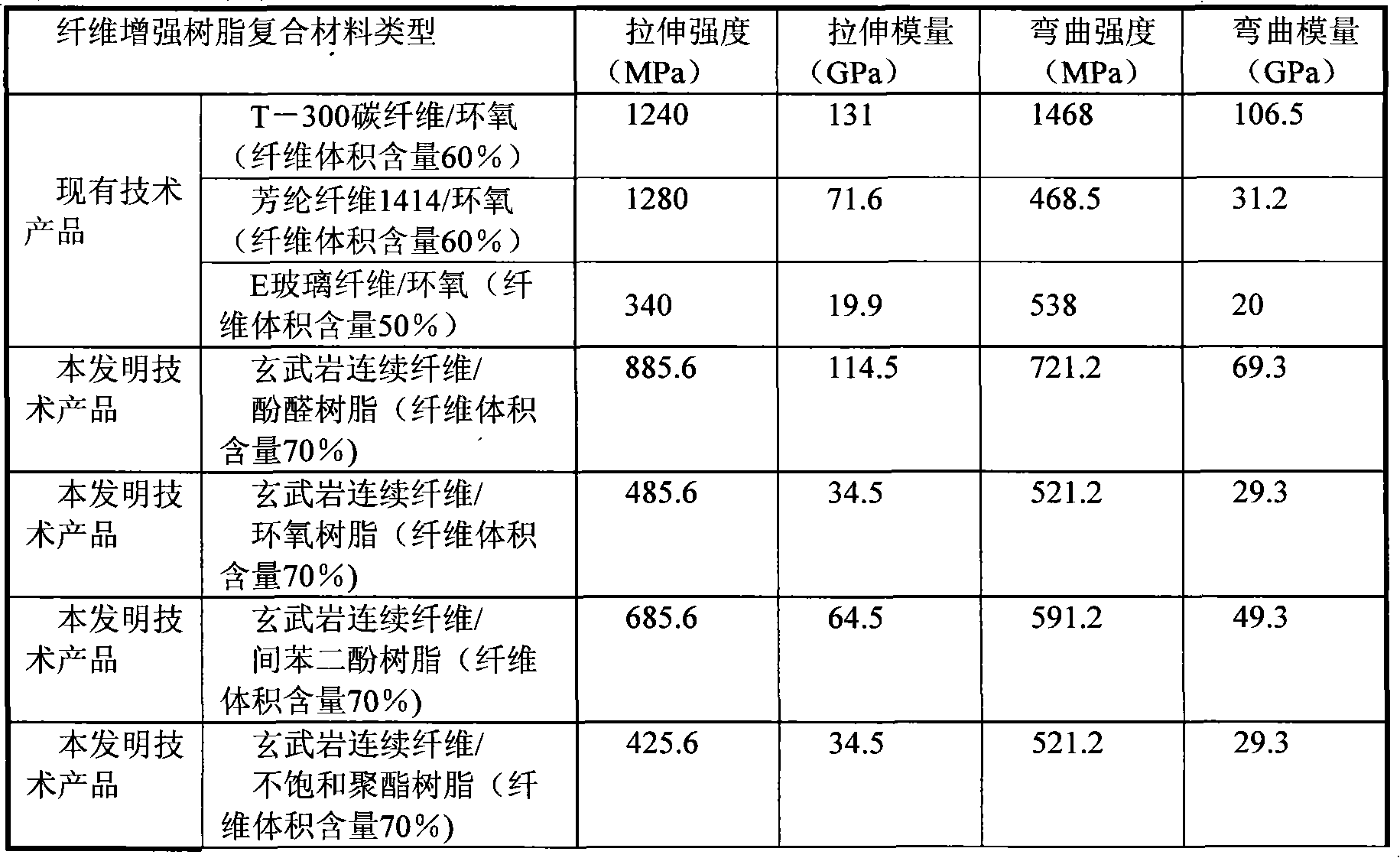

Basalt continuous fibre enhancement resin composite material and manufacturing method thereof

The invention discloses a basalt continuous fiber reinforced resin composite material and a relative production method, which uses basalt continuous fiber as reinforce material, uses the chemical material containing the silane compounds as coupling agent, and uses unsaturated polyester resin, phenol resin, epoxy resin, resorcinol resin, amino resin and vinyl resin, or modified unsaturated polyester resin, phenol resin, epoxy resin, resorcinol resin, amino resin and vinyl resin as substrate, to produce basalt continuous fiber reinforced resin composite material. The physical properties of the basalt continuous fiber reinforced resin composite material are better than glass fiber reinforced resin, and the hydrolysis resistance and corrosion resistance of basalt continuous fiber are better than glass fiber, with better performance price ratio than carbon fiber and Kevlar fiber. The basalt continuous fiber has better high temperature resistance, fireproof property, better combination property and low cost.

Owner:BEIJING FORESTRY UNIVERSITY

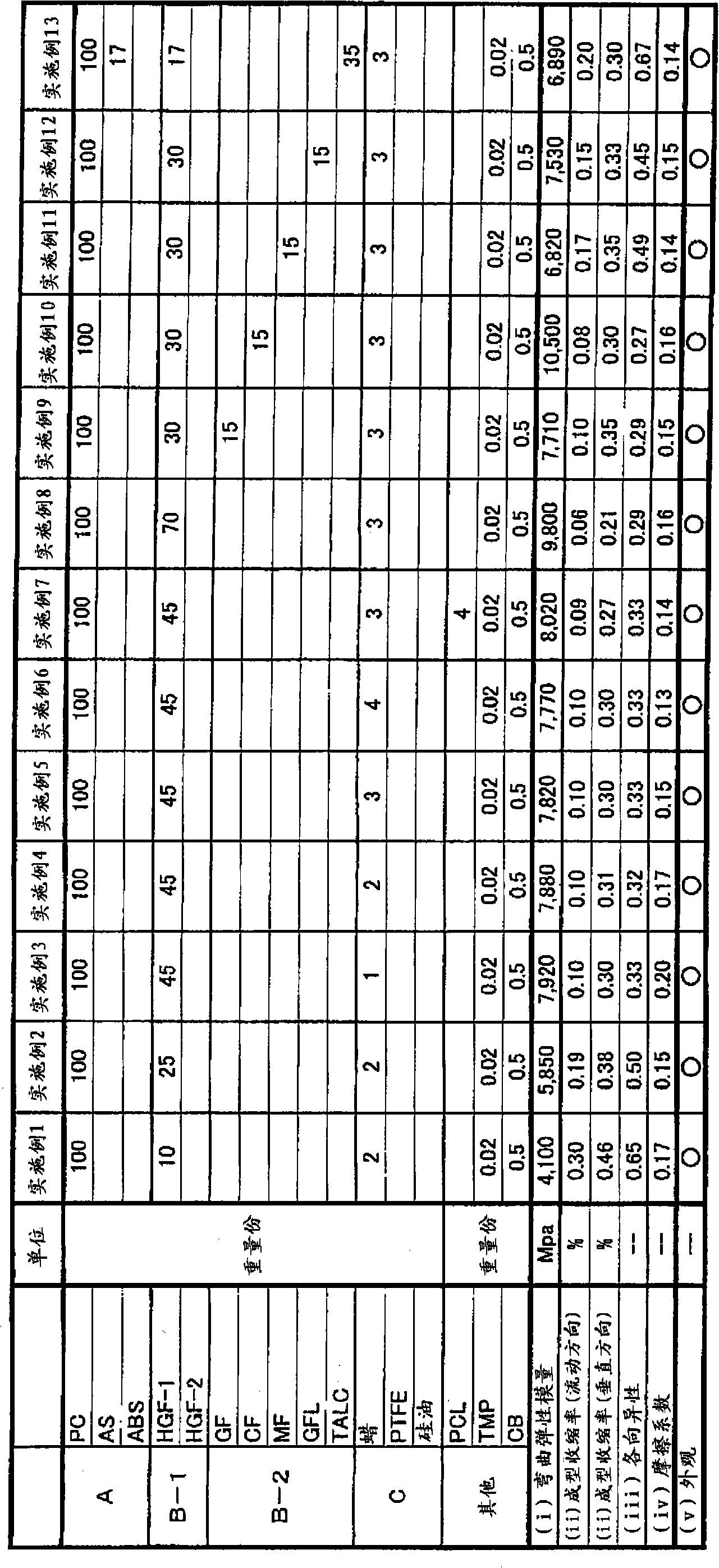

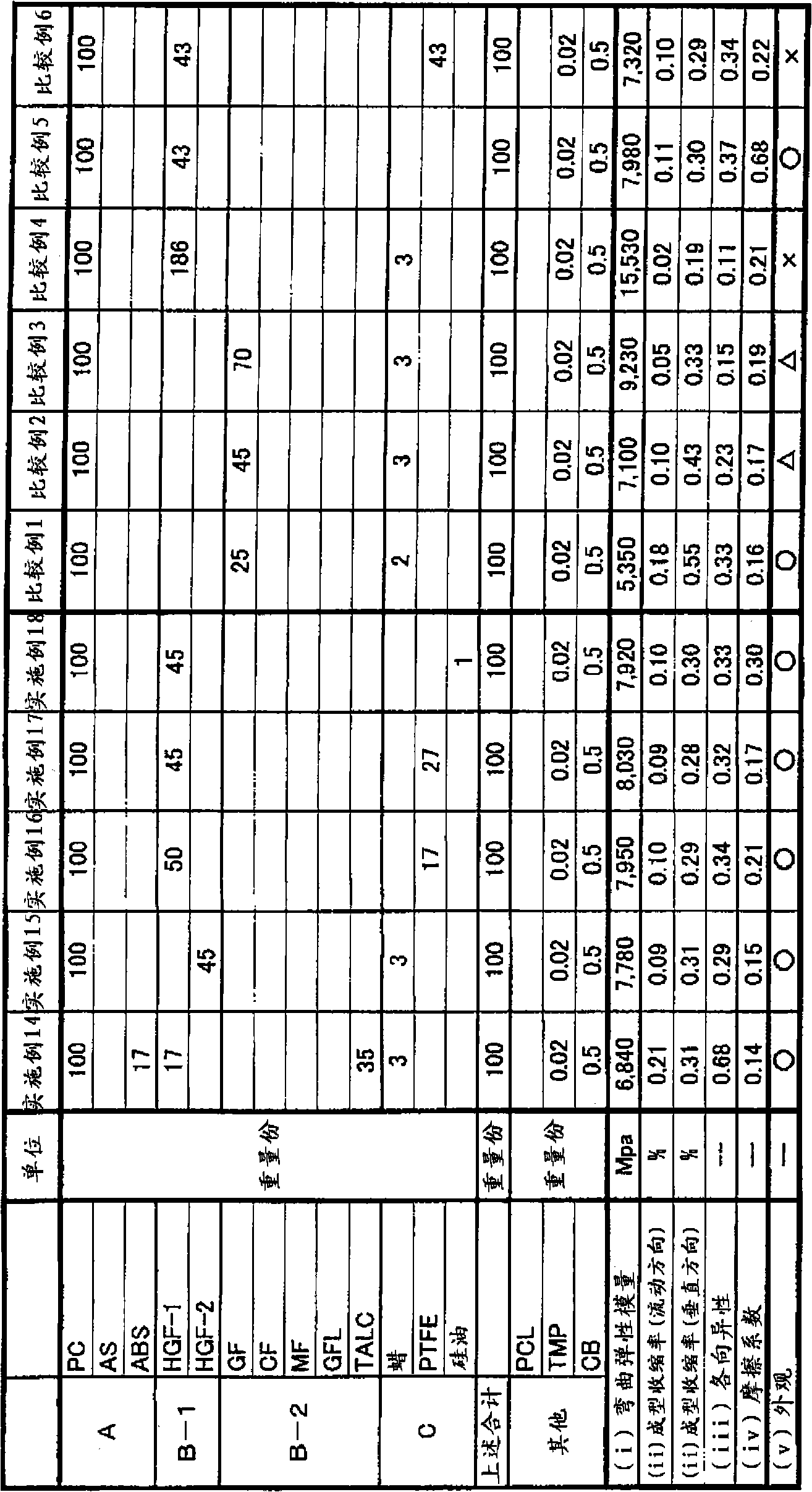

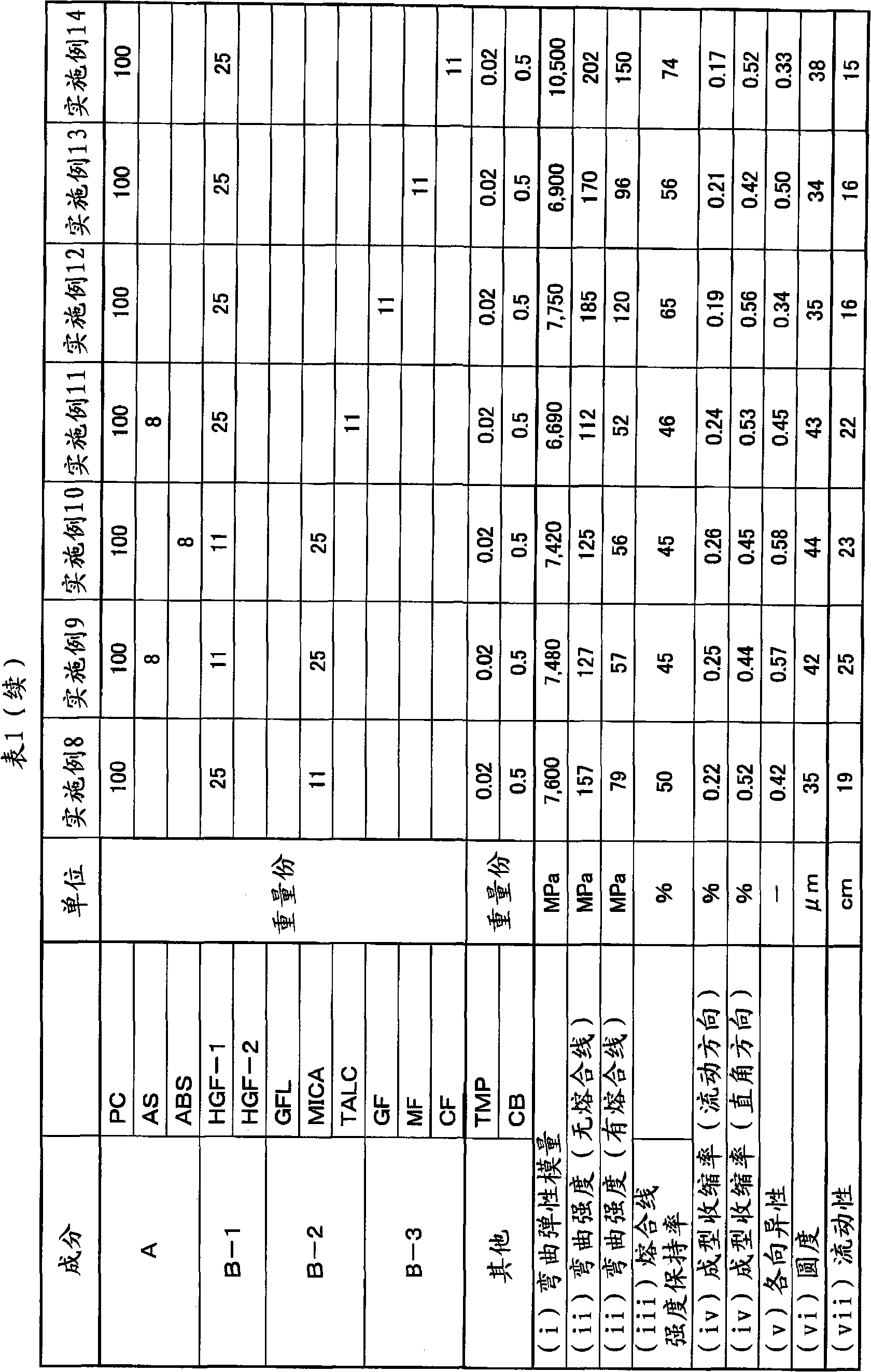

Glass fiber reinforced resin composition

The present invention relates to a glass fiber reinforced resin composition. The objective is to provide a resin composition based on flat cross section glass fiber reinforced thermoplastic resin and having excellent mechanical strength, small aeolotropism of mold shrinkage, good appearance and sliding characteristic. The resin composition contains (A) thermoplastic resin (component A) containing aromatic polycarbonate resin (component A-1); (B) flat cross section glass fibre (component B-1) that an average value of long diameters of the fibre cross section is 10-15[Mu]m, an average value of ratios of the long diameters and short diameters is 1.5-8, and filler material (component B-2), and (C) slide endowing agent (component C), wherein relative to 100 parts of component A by weight, the resin composition contains 1-150 parts of B-1 by weight, 0-150 parts of B-2 by weight, and 0.1-30 parts of C by weight.

Owner:TEIJIN KASEK KK

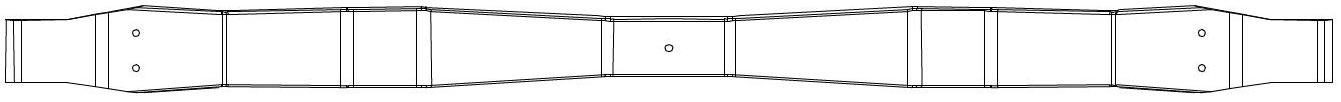

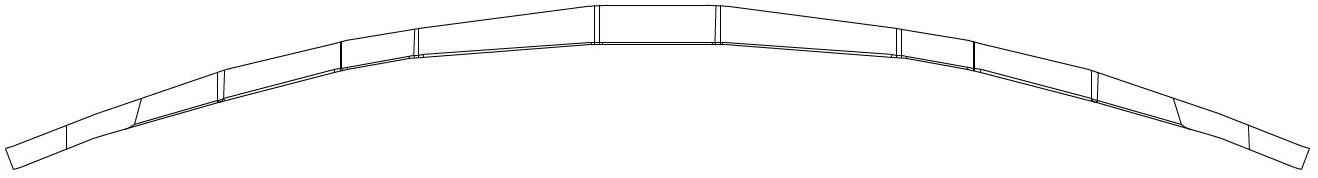

Preparation method for glass fibre reinforced resin composite plate spring

The invention relates to a preparation method for a glass fibre reinforced resin composite plate spring. The method comprises the following steps of: respectively soaking a glass fibre cloth and a glass fibre filament in epoxy resin, laying a layer on the upper and lower surfaces of a core model by using the glass fibre cloth; in the case of existing a preset value of the appropriate tensile force, winding the glass fibre filament on the core module, wherein the applied tensile force to the glass fibre filament gradually decreases along with the number of winding layers in the winding process; laying a layer of glass fibre cloth after the completion of winding; performing die assembly by the conventional manner to obtain an incompleted plate spring in embryo, and solidifying to obtain the glass fibre reinforced resin composite plate spring. The plate spring product prepared by the method provided by the invention has more excellent strength, is stronger in fatigue resistance than steel materials and is above 60% lighter in weight than the steel plate spring.

Owner:北京国材汽车复合材料有限公司

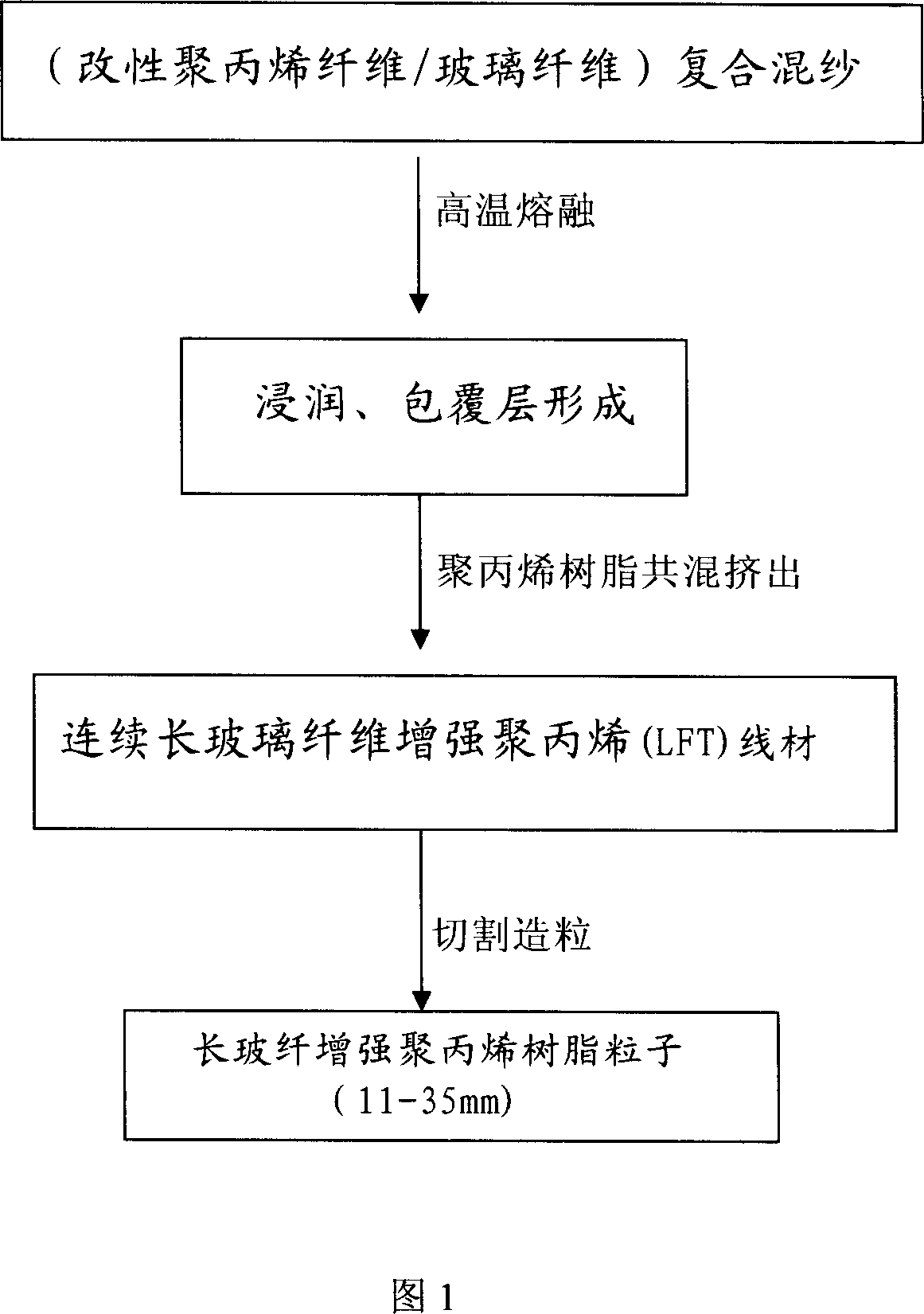

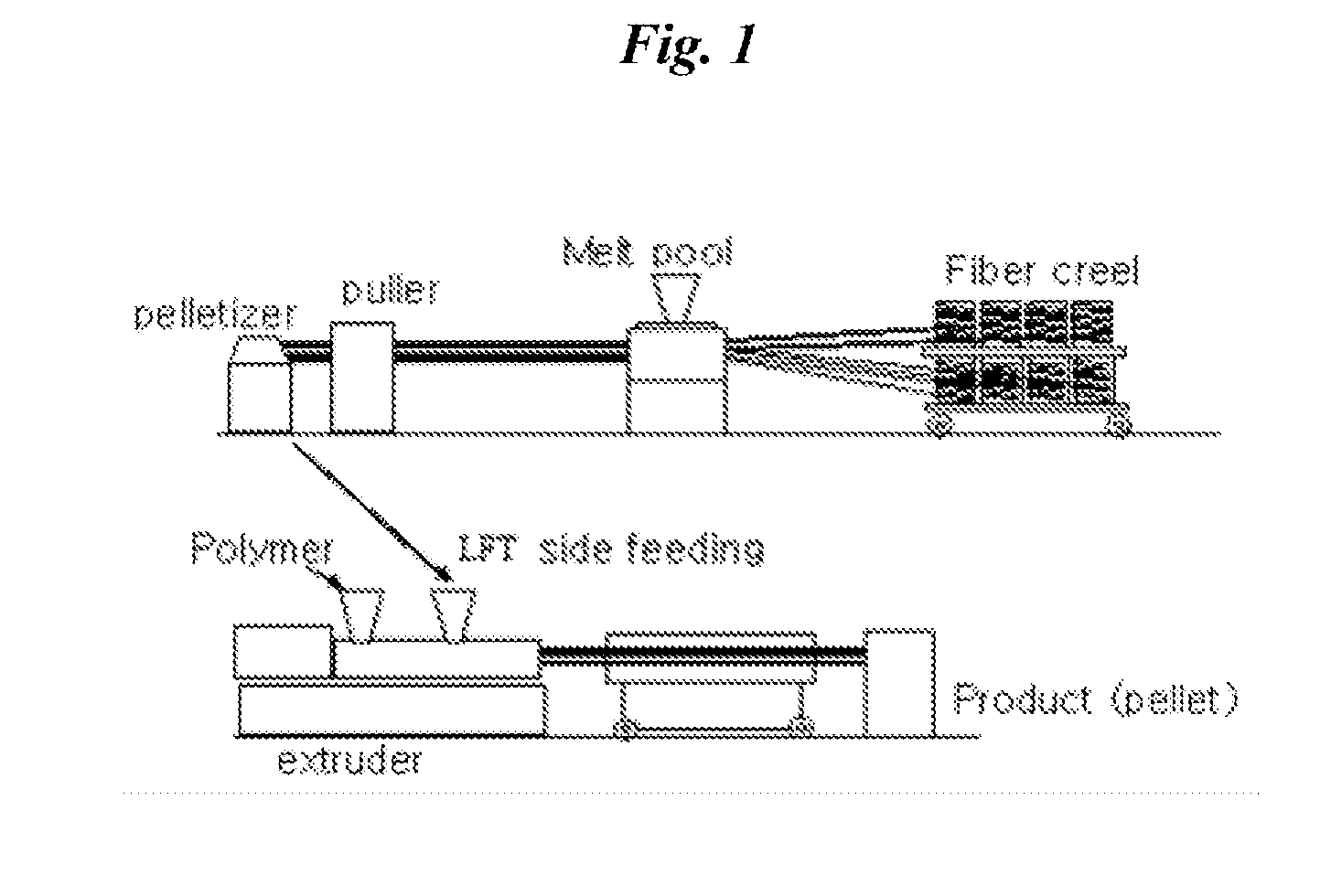

Continuous long glass fiber reinforced profax resin granular material preparation method

The invention discloses a preparing method of fiber reinforced polypropylene resin particle of continuous long-glass (LGFPP), which comprises the following steps: blending 20-80% composite yarn with glass fiber, 5-60% thermoplastic polypropylene resin and 1-15% adjuvant; heating; fusing; squeezing; graining; setting the weight rate of modified polypropylene fiber and glass fiber at 1:99-50:50 as the component of composite yarn.

Owner:TAIAN SAIGANG COMPOSITE MATERIAL

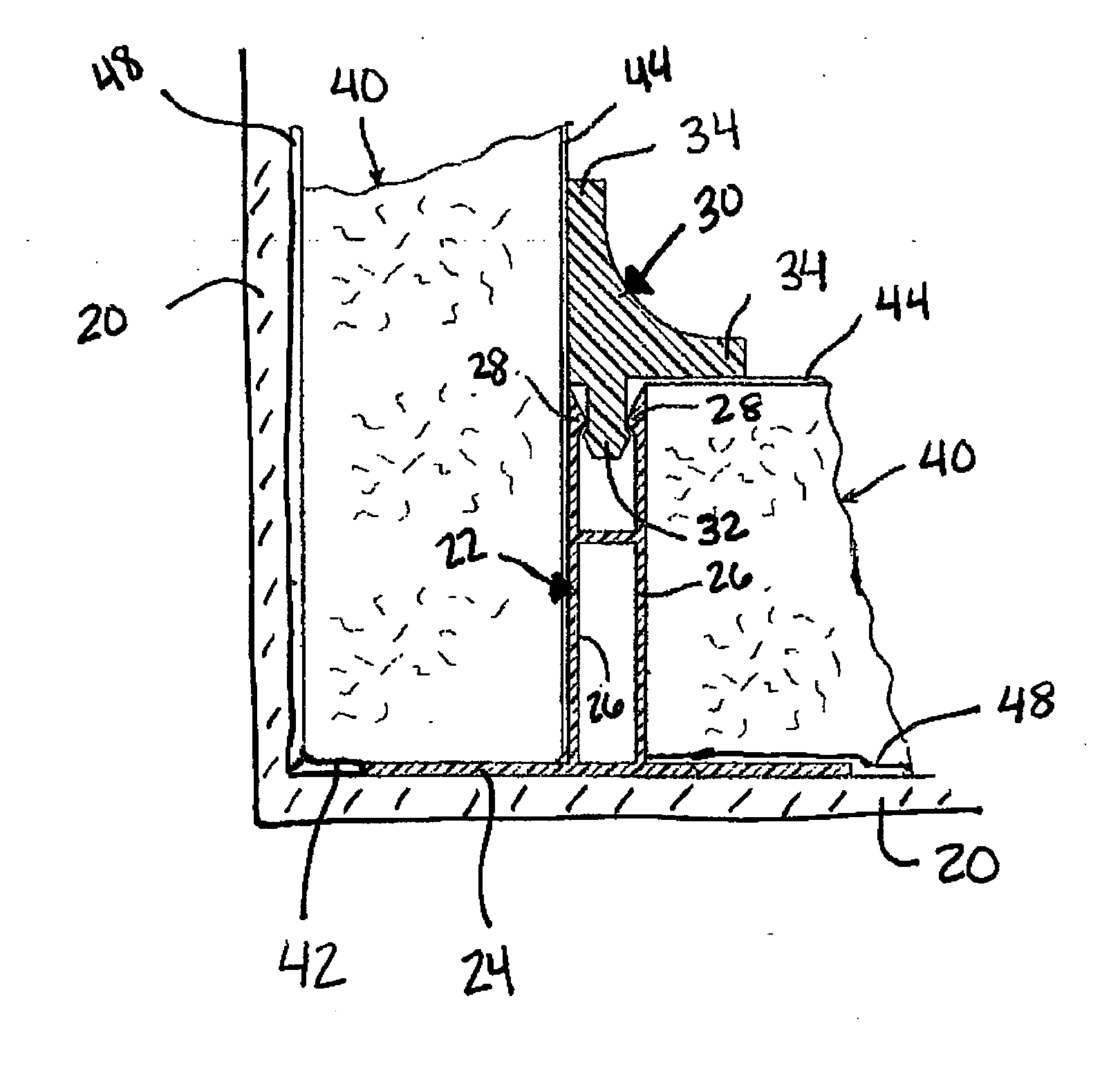

Acoustic partition for removable panel finishing system

InactiveUS20070125011A1Easy to cutReduce echo timeWallsSound proofingGlass fiberBituminous materials

An acoustical absorbing membrane that may be used in removable panel finishing systems is provided. The acoustic membrane may be formed of any sound transmission loss material that possesses sound-absorbing or sound-deadening qualities. Examples of suitable materials include foil, a foil-faced asphalt material, elastomeric materials, composite laminates, a polymer film, a composite material formed of an organic bonding material and one or more types of reinforcement fibers, a cement board, a gypsum board, a gypsum / WUCS board, a dense WUCS mat, a film formed of a fiberglass reinforced resin, and / or any dense polymeric material. In at least one exemplary embodiment, the acoustic membrane may be a film formed of a loaded polymer or copolymer, such as a copolymer of ethylene-vinyl acetate loaded with barium or CaCO3. The acoustic membrane may have a density of approximately 1 lb / ft2-3 lbs / ft2 and preferably has a thickness from about 1 / 16-⅜ of an inch.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Composite material prepreg for restoring ultraviolet light curing structure and preparation method thereof

InactiveCN104312192AImprove light curing efficiencyMeet curing requirementsGlass fiberUltraviolet lights

The invention provides a composite material prepreg for quickly ultraviolet light curing a resin base structure reinforced by glass fibers with certain thickness and a preparation method thereof. In the method, a common free radical curing resin as a matrix, a proper photoinitiator, a thermal initiator and other assistants are preferably selected to form a light-thermal composite initiation system, a glass fiber textile is used as a reinforcement material, and the composite material prepreg with a certain thickness is prepared by a proper compound process. The prepreg can be cured by irradiating ultraviolet light on a single surface for 10 minutes, and the light curing thickness at one time can be higher than 15 mm. By adopting the invention, the existing technical problem that the ultraviolet light cannot be used for curing composite material structural members with large thicknesses (10-15 mm and larger) at one time is solved, the composite material prepreg is cured more conveniently and efficiently. The light-cured resin and the composite material thereof express huge application prospect and market potential in some special fields, for example, trenchless repair of municipal drainage pipelines.

Owner:WUHAN UNIV OF TECH

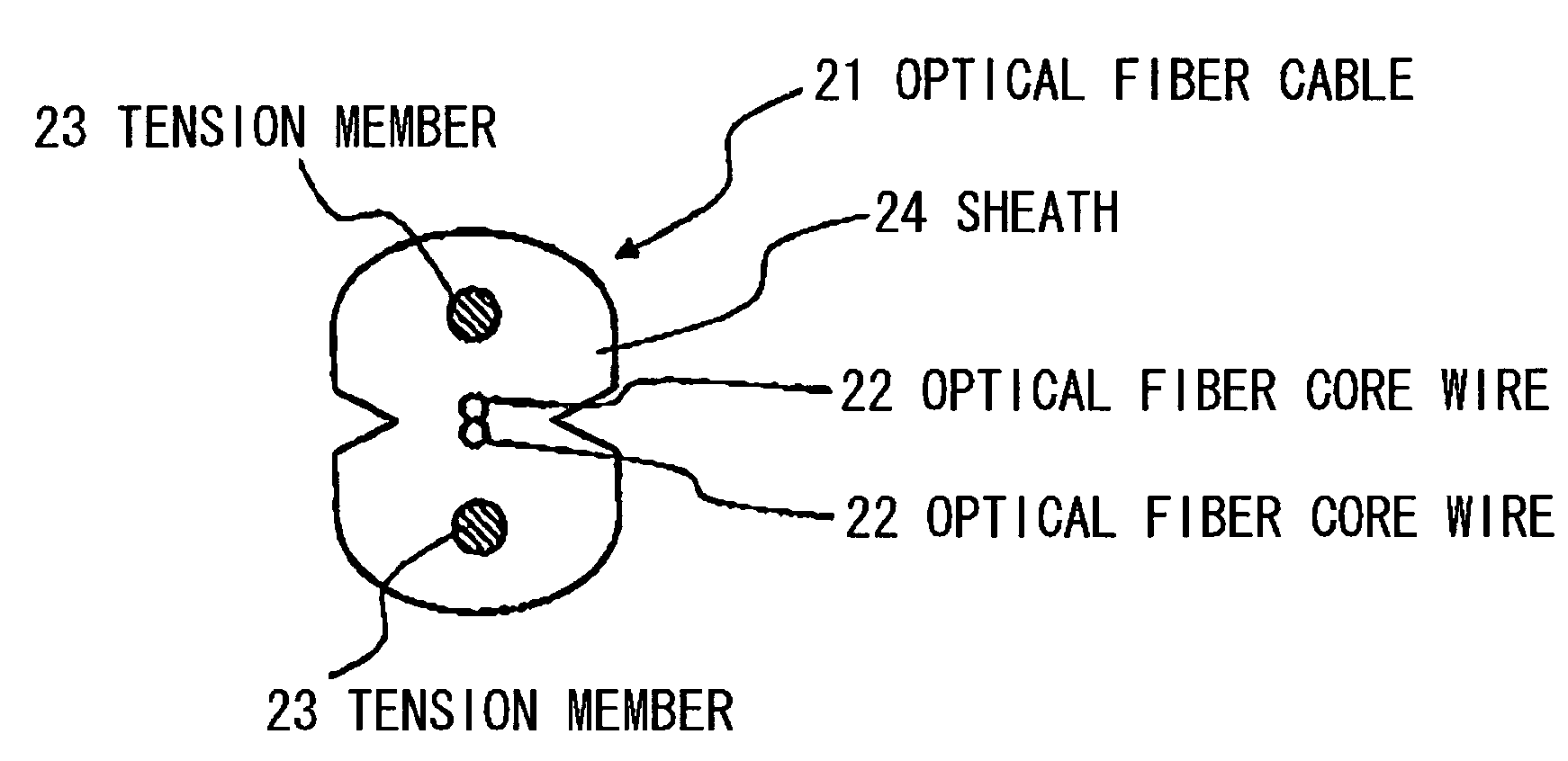

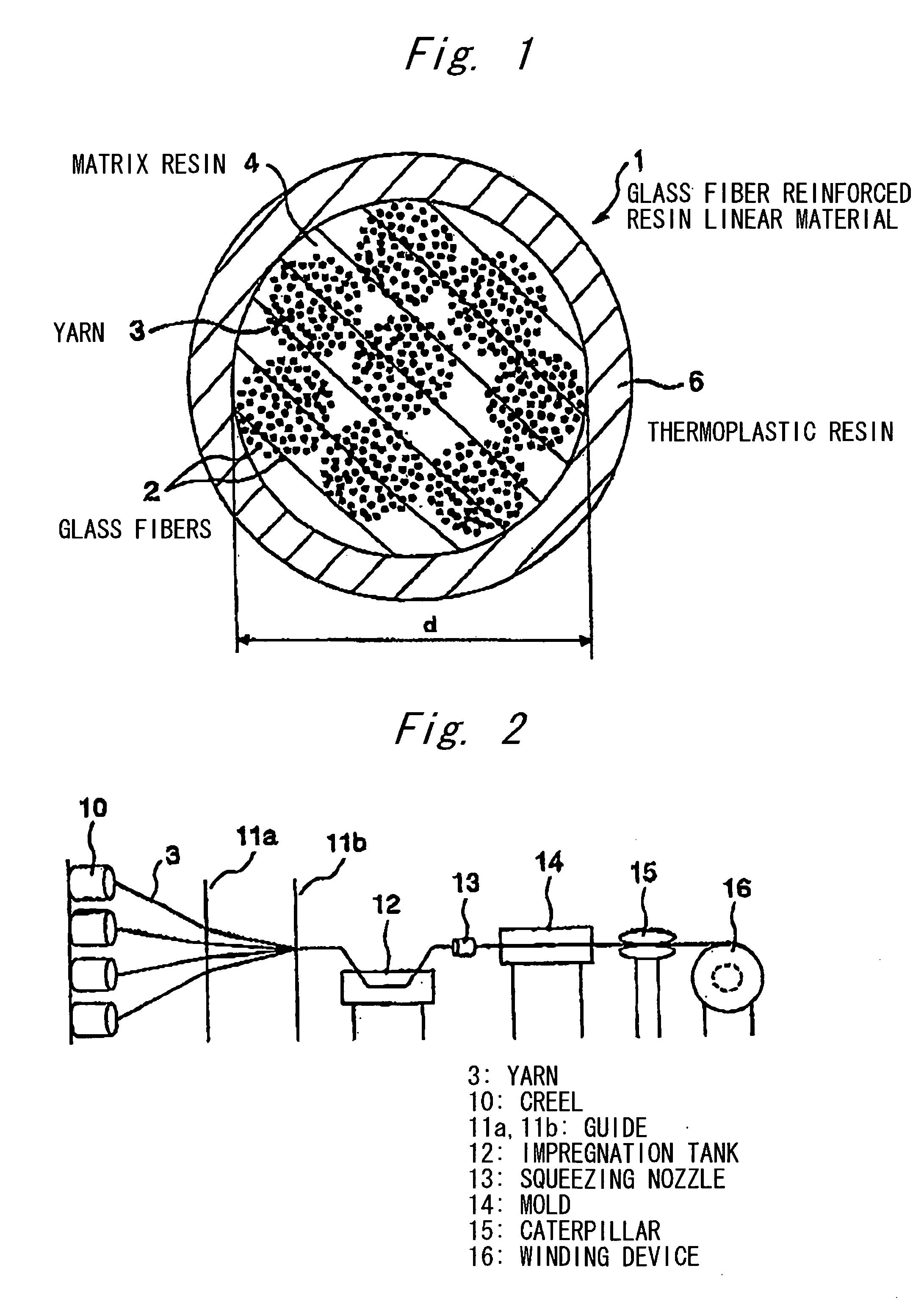

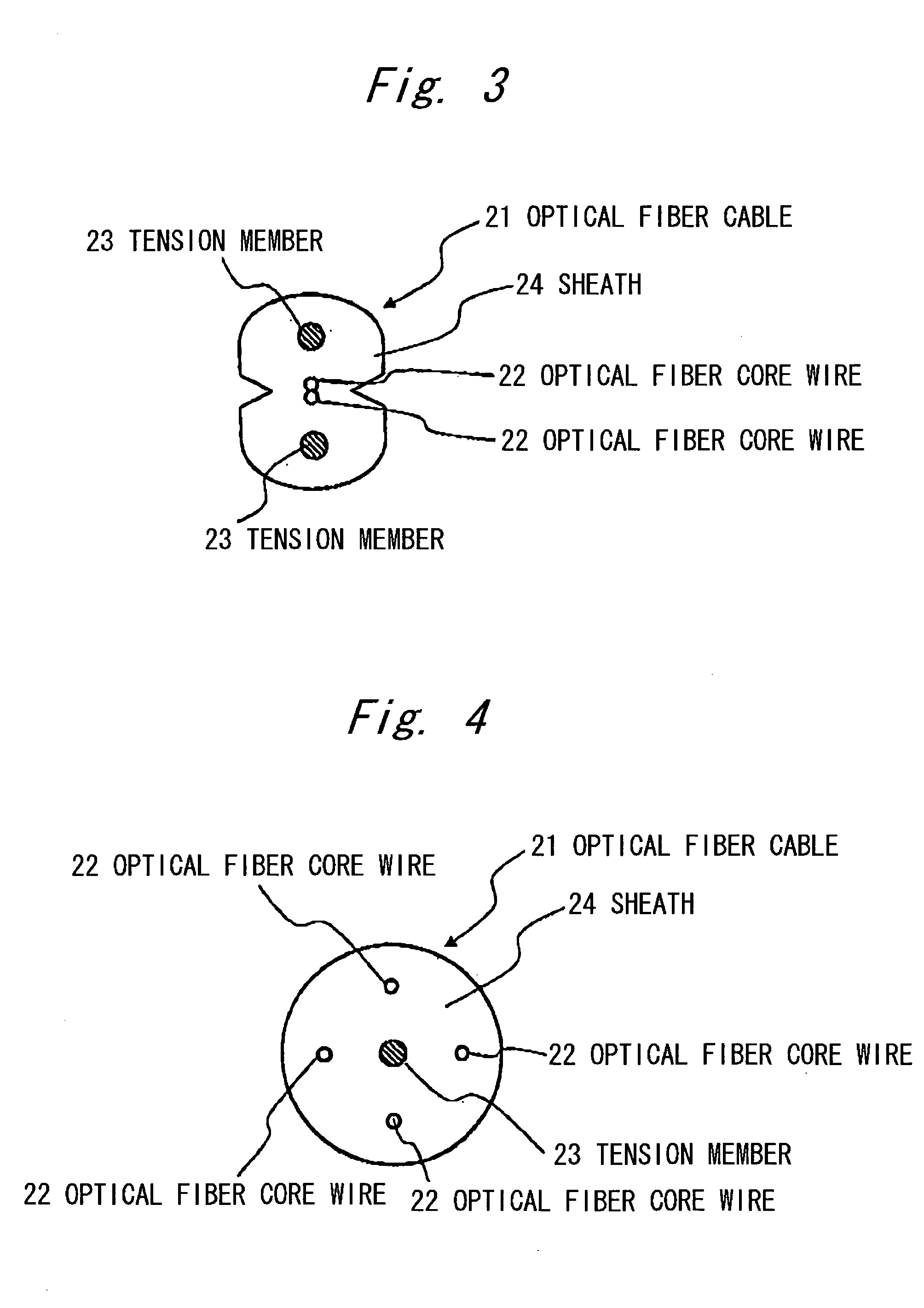

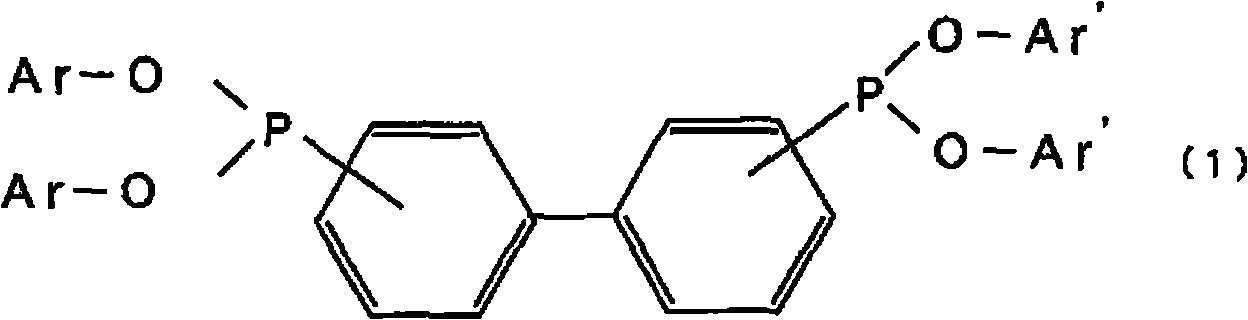

Optical fiber cable

InactiveUS20050238299A1Improve the level ofImprove bending performanceCladded optical fibreFibre mechanical structuresGlass fiberTension member

An optical fiber cable has an optical fiber core wire and a tension member. The tension member is formed of a glass fiber reinforced resin linear material with glass fibers and a matrix resin, and satisfies the following requirements: (1) (EfVf+EmVm)d2≧8.3 / n wherein Ef represents the modulus of elasticity of glass fibers, GPa; Vf represents the content of glass fibers, % / 100; Em represents the modulus of elasticity of matrix resin, GPa; Vm represents the content of matrix resin, % / 100; d represents the diameter of tension member, mm; and n represents the number of tension members used in optical fiber cable; (2) (Ef / Em)≧22; (3) Vf=0.6 to 0.88; and (4) an elongation at break of glass fibers of not less than 5% and an elongation at break of matrix resin of not less than 5%.

Owner:HITACHI CABLE

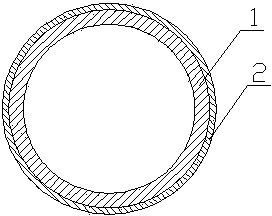

Cylinder produced from glass fiber-reinforced resin composition

The object of the invention is to provide a cylinder produced from glass fiber-reinforced resin composition. The cylinder uses thermoplastic resin which is reinforced by glass fiber with flat cross section as substrate, and has the advantages of mechanical intensity, low aeolotropism, good fluidity and excellent appearance. The cylinder is molded by being injected with resin composition, and the resin composition contains: (i) 100 proportion by weight of resin component (A component) containing aromatic polycarbonate resin (A-1 component); (ii) 1-150 proportion by weight of fiberglass (B-1 component) with flat section, whose mean value of long diameter of fibre section is 10-50 mu m, and mean value of ratio between the long diameter and the short diameter (long diameter / short diameter) is 1.5-8; as well as (iii) 0-150 proportion by weight of reinforced filler material, which is one of plate-shaped filler material (B-2 component) and fibrous filler material (B-3 component) besides B-1 component.

Owner:TEIJIN KASEK KK

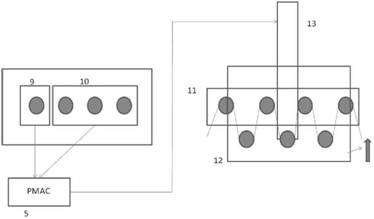

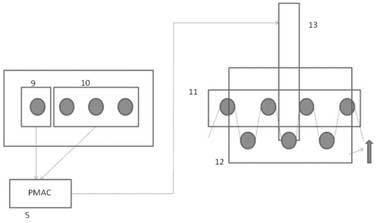

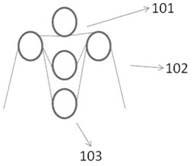

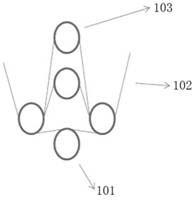

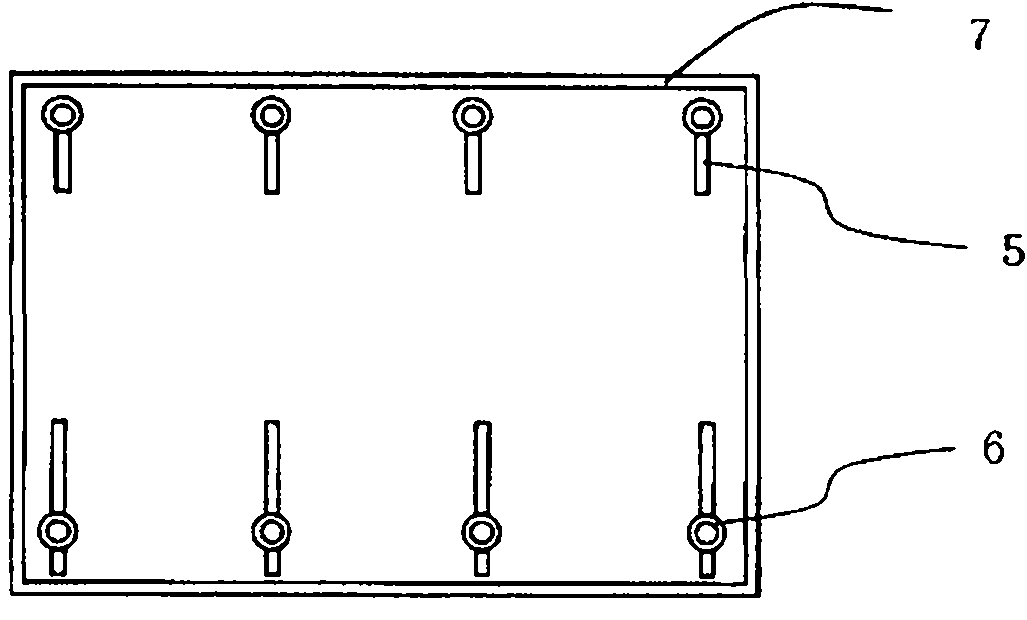

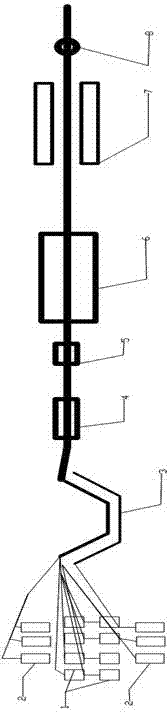

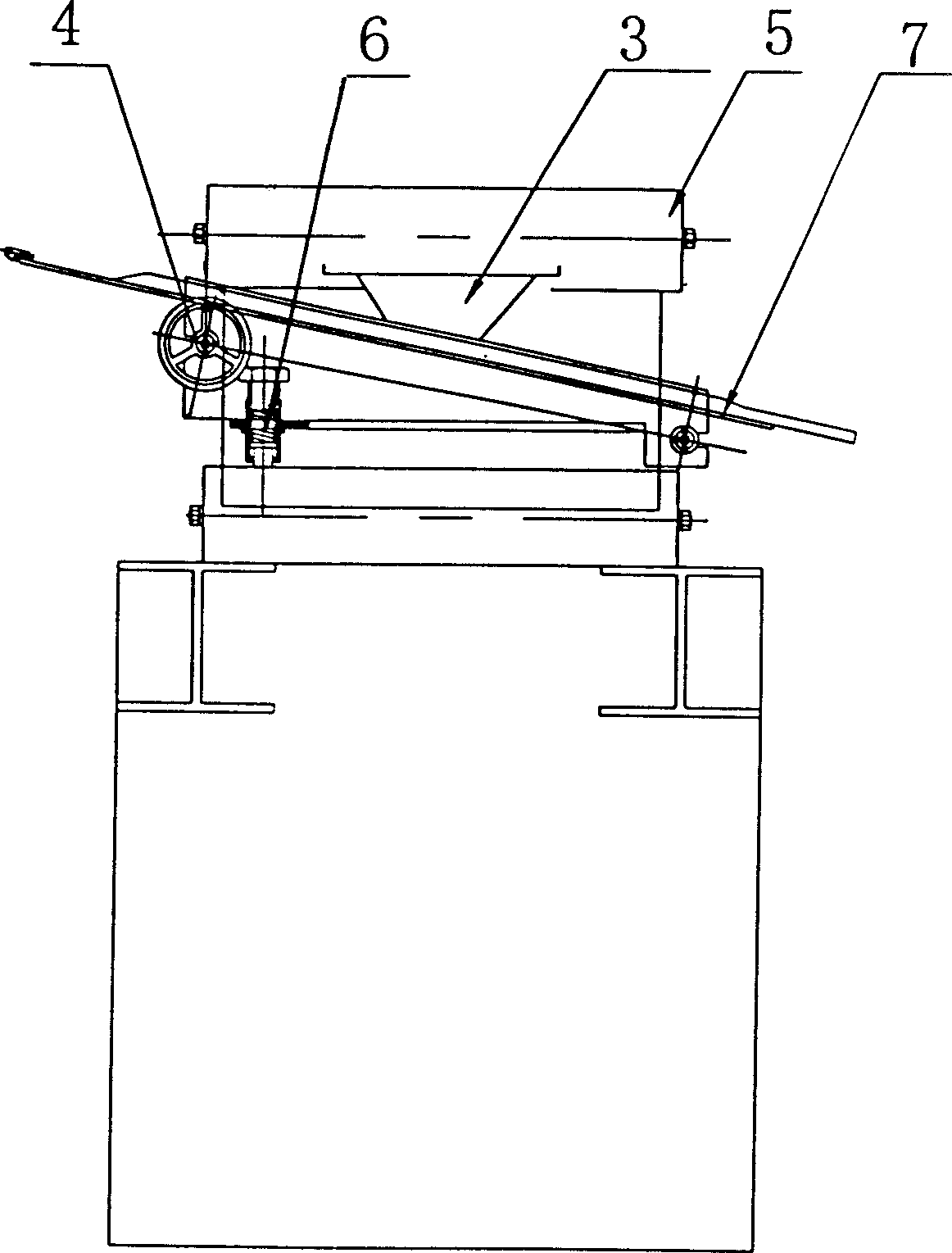

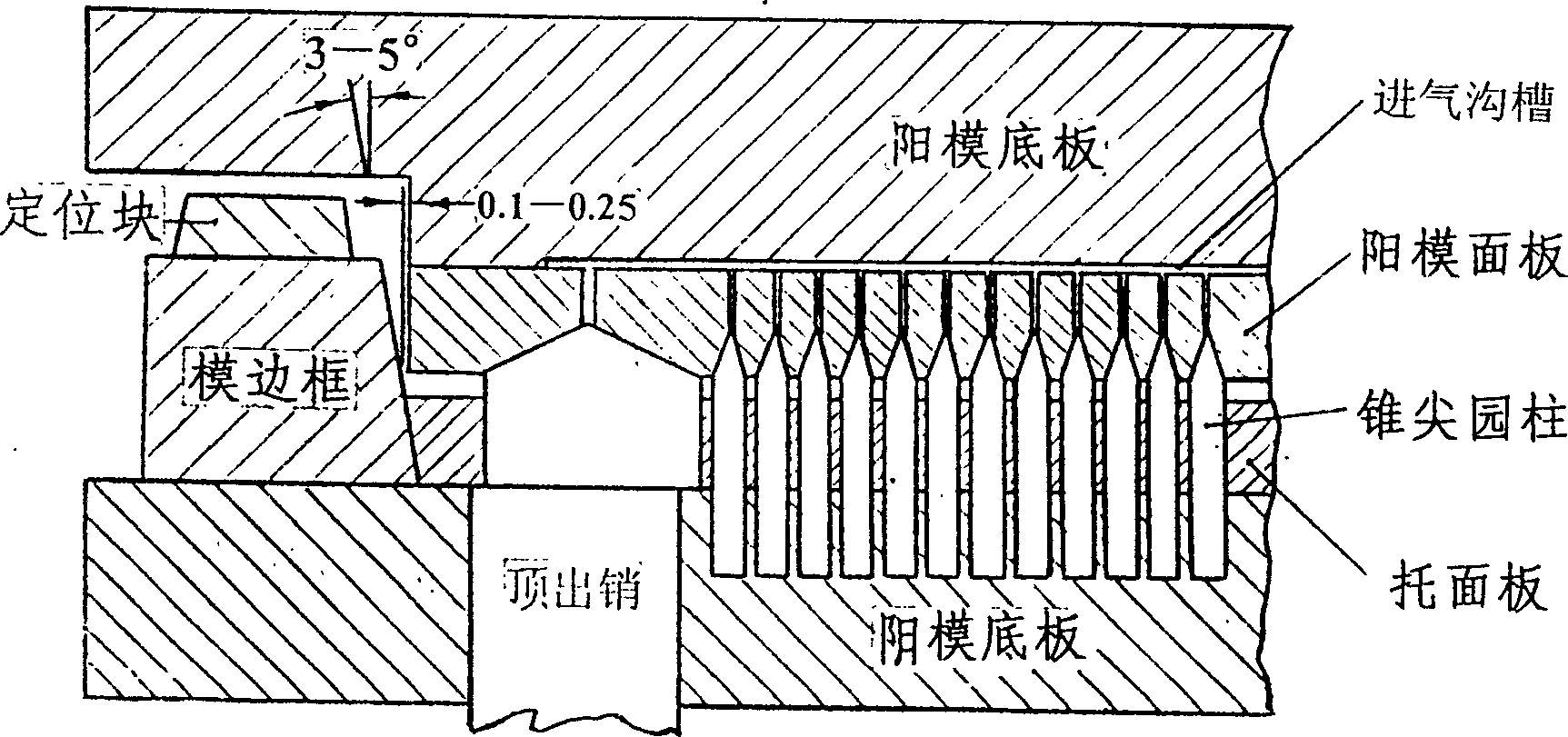

Manufacture device of glass fibre reinforced resin composite plate spring

The invention provides a manufacture device of a glass fibre reinforced resin composite plate spring. The manufacture device comprises a yarn roller, a gum dipping groove, a tension controller and a PMAC (Programmable Multi Axis Controller) controller, wherein the gum dipping groove is connected with the tension controller, the tension controller is connected with the PMAC controller, and a motor is arranged between the tension controller and the PMAC controller; the tension controller comprises a speed sensor, a tension sensor and a mechanical part which are respectively controlled by the PMAC controller; and the mechanical part comprises a group of fixed friction rollers and a group of mobile friction rollers. The manufacture device of the glass fibre reinforced resin composite plate spring can realize real-time monitoring and controlling to the fibre tension; and the tension valve required by each stage can be preset, and the tension condition of the fibre can be changed in real time according to different preset tension valves in a fibre material twisting process.

Owner:北京国材汽车复合材料有限公司

Load bearing window

Owner:THE BOEING CO

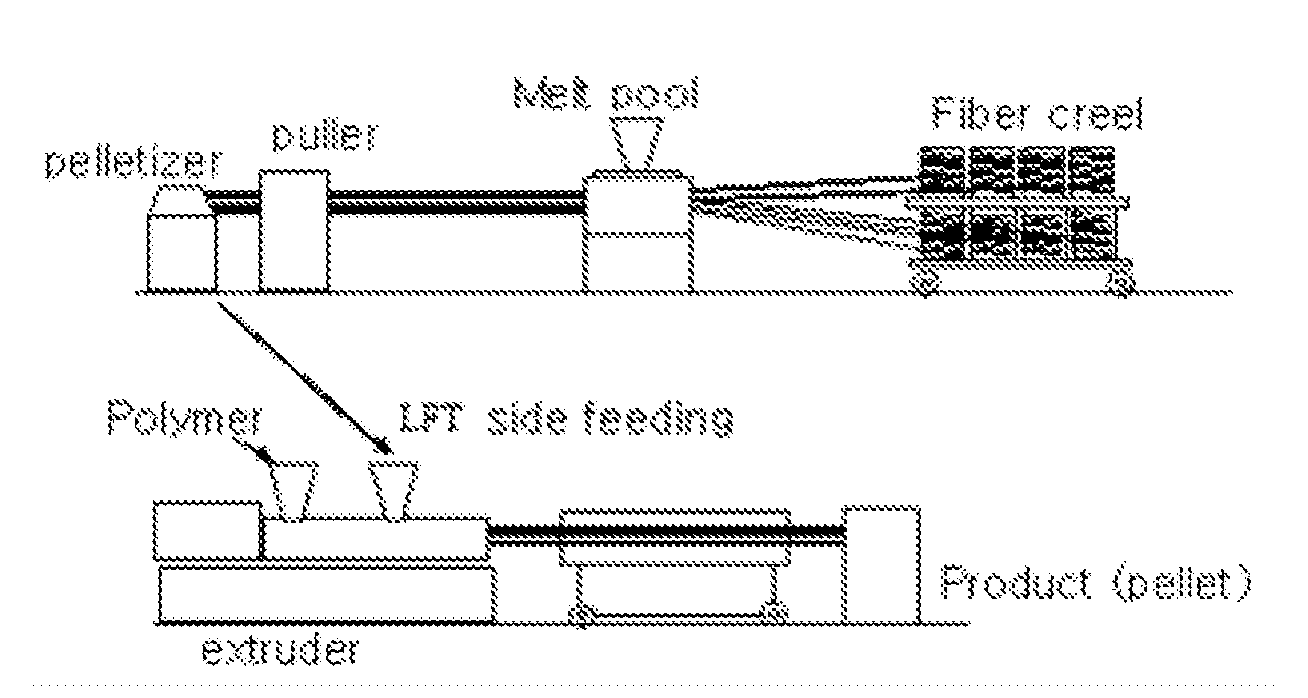

Long Glass Fiber Reinforced Resin Composite and Method for Preparing the Same

InactiveUS20120190785A1Improve mechanical propertiesDifferent viscositySpecial tyresGlass fiberFlexural modulus

A long glass reinforced resin composite of the present invention may comprise two kinds of thermoplastic matrix resin (a1, a2) which have different viscosities and a long glass fiber (B). The method of preparing the long glass reinforced resin composite comprises preparing a LFT (Long fiber thermoplastic) master-batch composition by impregnating the long glass fiber (B) of continuous phase into the low viscosity thermoplastic resin (a2), and compounding the LFT (Long fiber thermoplastic) master-hatch composition with high viscosity thermoplastic resin. The long glass fiber reinforced resin composite of the present invention has excellent mechanical properties such as impact strength, tensile strength, and flexural modulus.

Owner:LOTTE ADVANCED MATERIALS CO LTD

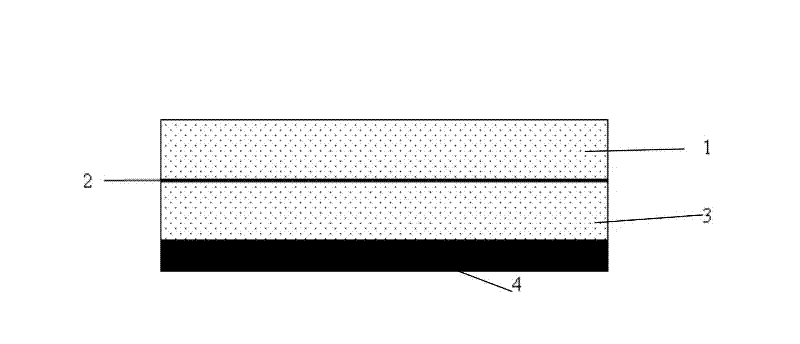

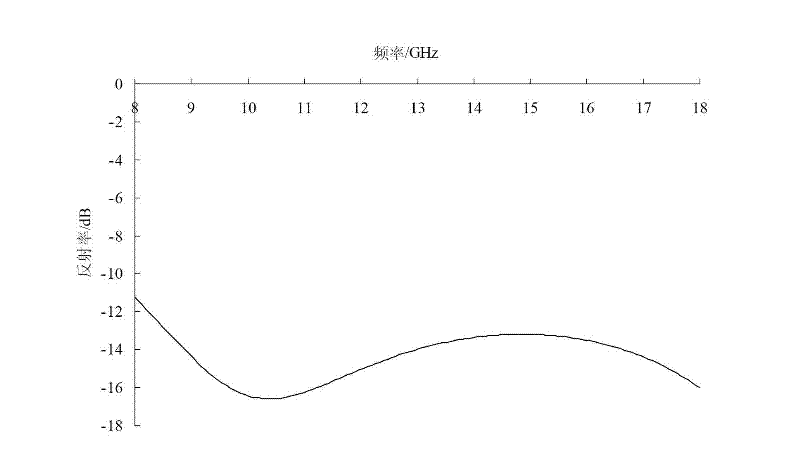

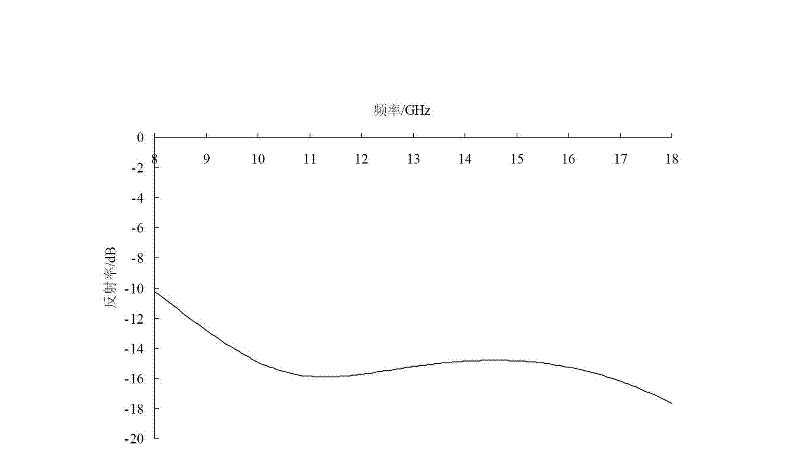

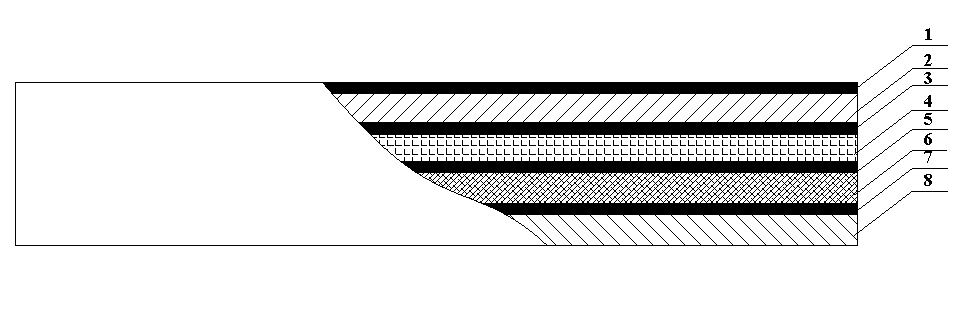

Hybrid fiber reinforced resin matrix sandwich structural absorbing material and its preparation method

ActiveCN102229267AImprove toughnessHigh strengthSynthetic resin layered productsGlass/slag layered productsGlass fiberCarbide silicon

The invention discloses a hybrid fiber reinforced resin matrix sandwich structural absorbing material and its preparation method. The absorbing material has a multifunctional laminated structure from the outside to the inside comprising a first dielectric layer, an absorbed layer, a second dielectric layer and a reflecting layer, wherein the first dielectric layer and the second dielectric layer are both composed of a glass fiber reinforced resin matrix composite material; the absorbed layer is composed of a continuous silicon carbide fiber reinforced resin matrix composite material; and the reflecting layer is composed of a carbon fiber reinforced resin matrix composite material. The preparation method of the absorbing material comprises the following steps of: firstly, each kind of fiber that satisfies each functional layer is selected; secondly, with the resin as the matrix, according to the laminated order and thickness of each functional layer, the absorbing material provided by the invention is prepared by the resin matrix composite material molding technology. The absorbing material provided by the invention has advantages of simple structure, good parameter tolerance, excellent wave absorbing function and low material cost, and furthermore is easy to mold.

Owner:NAT UNIV OF DEFENSE TECH

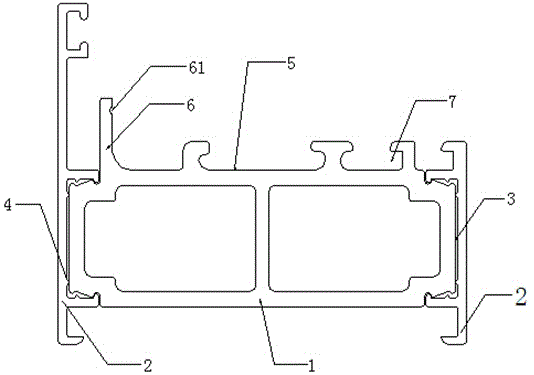

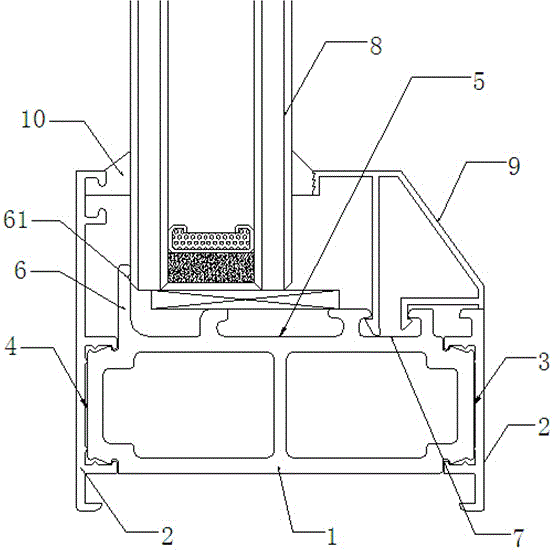

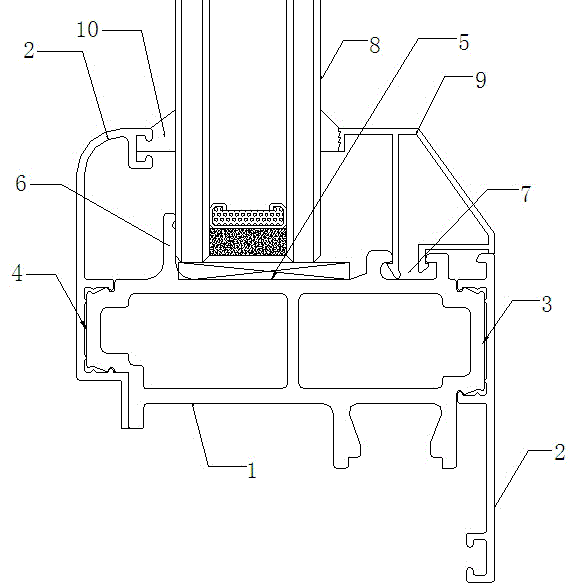

Composite sectional material and door/ window frame or glass curtain wall frame

ActiveCN104100173ALow thermal conductivityIncreased flexural modulusWallsSealing arrangementsGlass fiberWater tightness

The invention discloses a composite sectional material which has the same cross section at the different positions along the length direction. The composite sectional material comprises a continuous glass fiber reinforced resin sectional material and an aluminium layer taken as a decoration panel, and is used for preparing a door / window frame or a glass curtain wall frame; the continuous glass fiber reinforced resin sectional material is provided with one or two working surfaces for mounting glass as well as an inner wall and an outer wall respectively facing to the indoor space and the outdoor space; the aluminium layer is arranged on the outer wall of the continuous glass fiber reinforced resin sectional material; the working surface is provided with an installation mechanism used for installing the glass. According to the adopted composite sectional material, the installation mechanism is arranged, so that the continuous glass fiber reinforced resin sectional material becomes a main stress part of a door, a window or a curtain wall, and is not easily deformed; furthermore, the composite sectional material has better air tightness, heat insulation property, water tightness and sound insulation property, so that the stability and the strength of the whole door, window or curtain wall can be improved.

Owner:浙江德毅隆科技股份有限公司

Lens barrel made from glass fiber reinforced flame retardant resin composition

The invention provides a lens barrel made from glass fiber reinforced flame retardant resin composition, which is formed by injection molding the glass fiber reinforced flame retardant resin composition. The glass fiber reinforced resin composition contains 40-99 weight parts of aromatic polycarbonate resin (component A), 1-60 weight parts of reinforced filling material (component B), and 0.001-20weight parts of flame retardant (component C) with respect to 100 weight parts of the total weight of the component A and the component B. The reinforced filling material (component B) includes flatcross-section glass fiber (component B-1) with the long diameter of the cross-section of the fiber as 10-59 mu m, and ratio between the long diameter and the short diameter between 1.5-8, as well as round cross-section glass fiber (component B-2) with ratio between the average fiber length and the average fiber diameter lower than 10. The weight ratio between the component B-1 and the component B-2 of the reinforce filling material (component B) is from 5 / 95 to 95-5.

Owner:TEIJIN KASEK KK

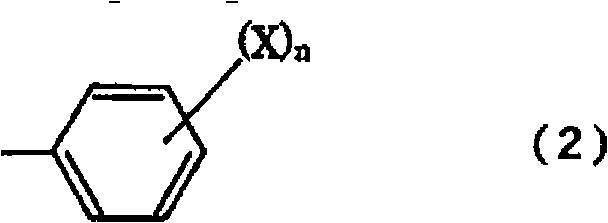

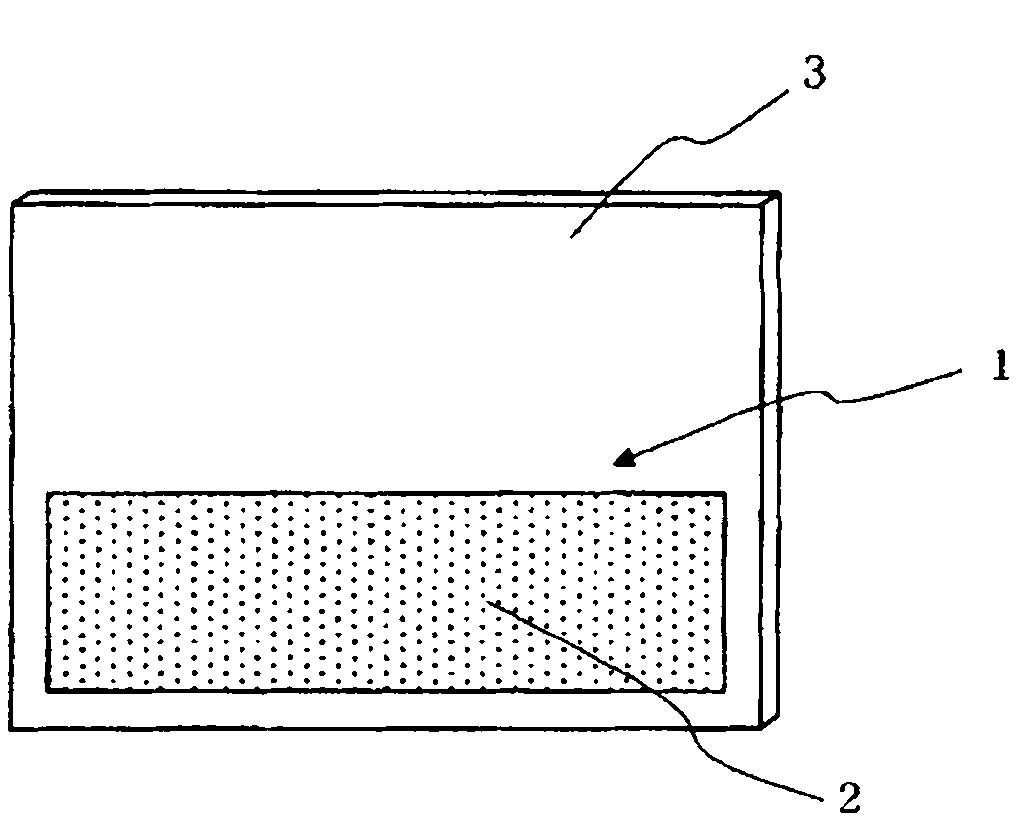

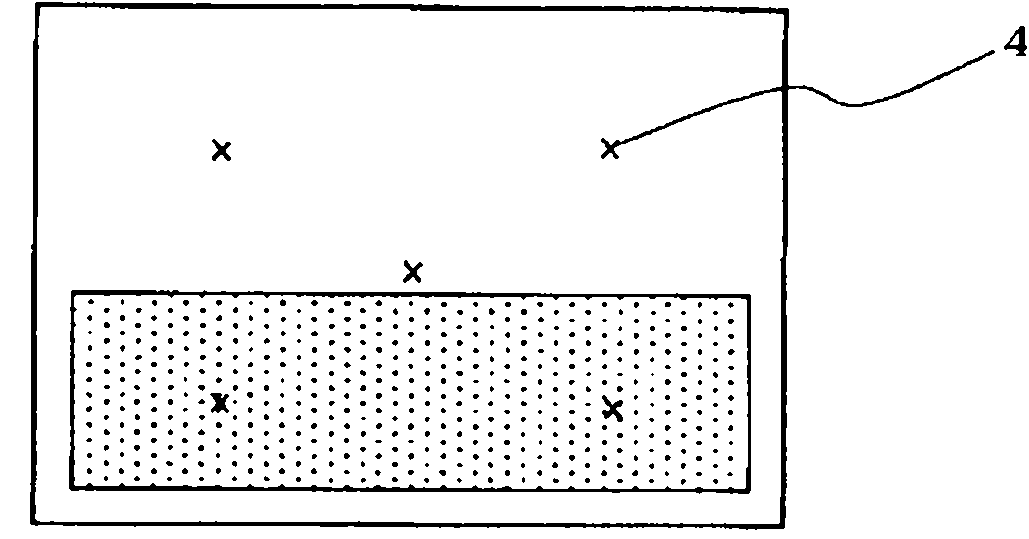

Photovoltaic component

InactiveCN102339883AImprove structural strengthSimple structurePhotovoltaic energy generationSemiconductor devicesGlass fiberEngineering

The invention discloses a photovoltaic component, which comprises a base plate, a photovoltaic layer and a transparent protection layer, wherein the base plate is made of a fiber glass reinforced resin; the photovoltaic layer is arranged on the upper surface of the base plate and comprises at least one photovoltaic cell; and the transparent protection layer is covered on the photovoltaic layer and is made of fluoroplastic. The photovoltaic component provided by the embodiment of the invention has the advantages of simple structure, light weight, low cost and the like.

Owner:JIUJIANG SUNID TECH

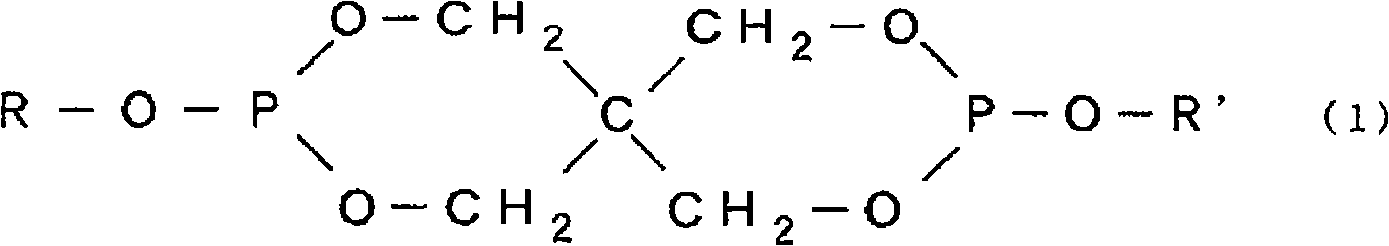

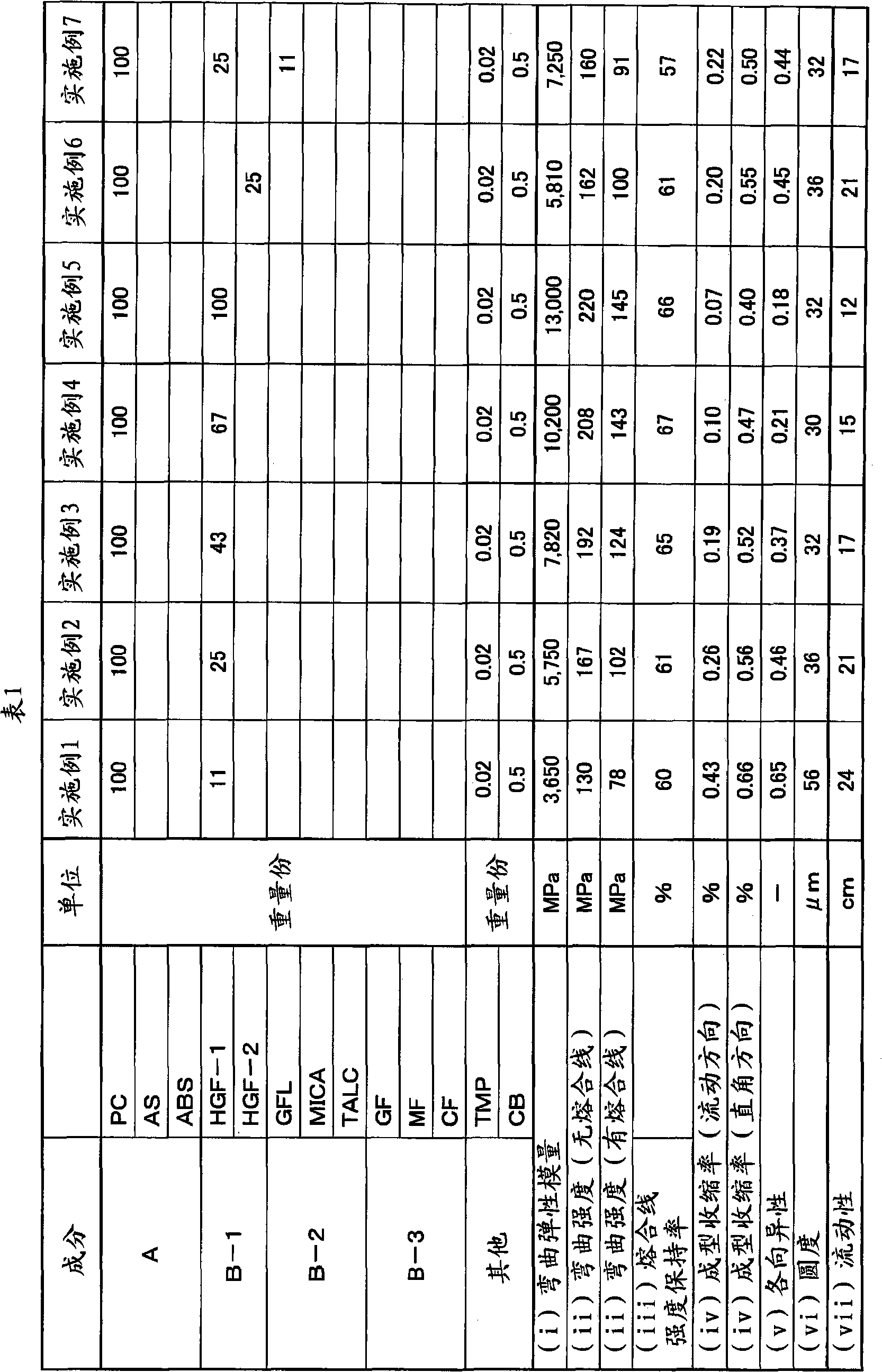

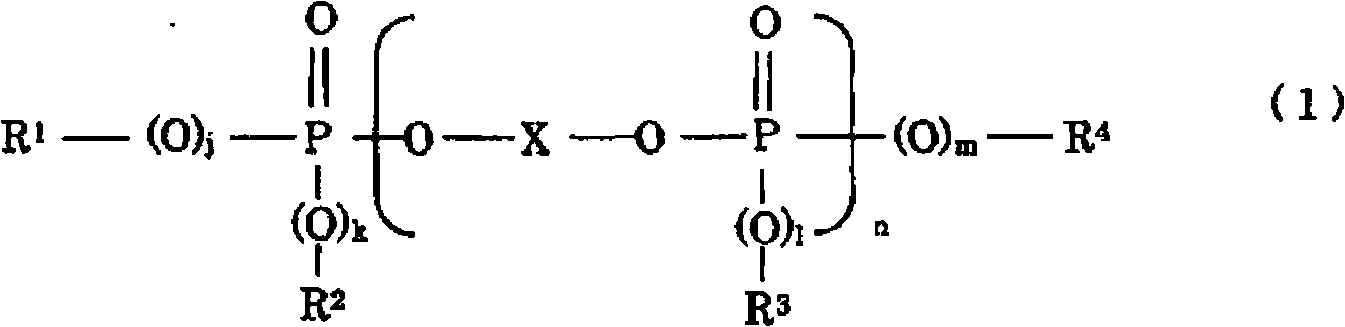

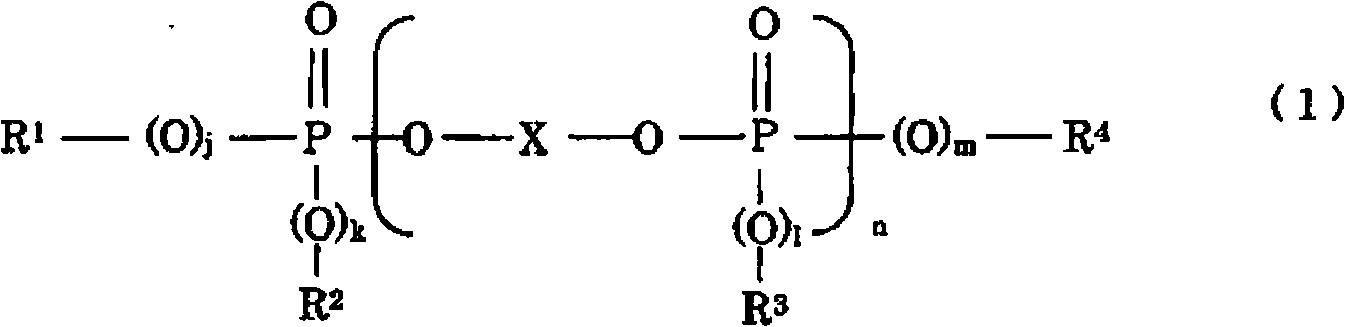

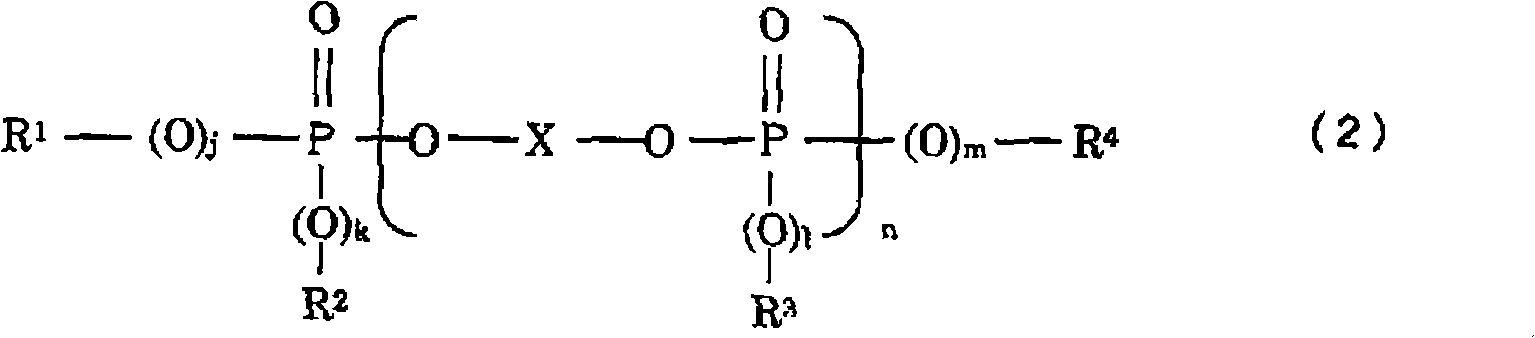

Electrical and electronic equipment part formed by injection moulding of glass fibre reinforced resin composition

The invention provides an electrical and electronic equipment part formed by the injection moulding of a glass fibre reinforced resin composition, wherein the resin composition containing a flat-section glass fibre reinforced polycarbonate resin is takes as a matrix, so that the electrical and electronic equipment part has excellent mechanical strength, less anisotropy of the form shrinkage and good flowability and flame resistance. The electrical and electronic equipment part is formed from the glass fibre reinforced resin composition comprising 40 to 65% by weight of thermoplastic resin (component A) and 35 to 60% by weight of reinforced filling materials (component B), and 1 to 30 weight portions of organic phosphate ester flame retardant (component C) based on 100 weight parts of the thermoplastic resin and the reinforced filling materials, the reinforced filling materials (component B) comprise flat-section glass fibre (component B-1) with the mean value of the long diameter of the fiber section being 10 to 50 mu m and the mean value of the ratio of the long diameter to the short diameter being 1.5 to 8, and other filling materials (component B-2) except the component B-1, the weight ratio of the component B-1 to the component B-2 is (10 to 90) to (100 to 0).

Owner:TEIJIN KASEK KK

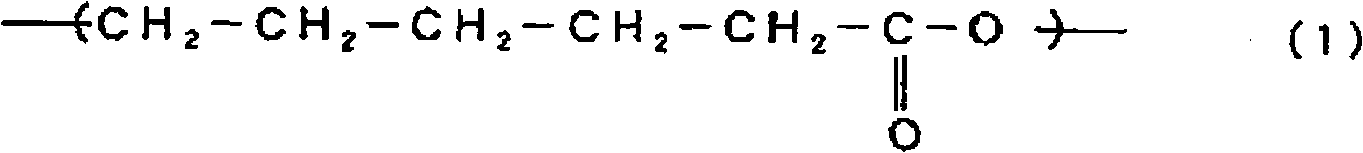

Glass fiber reinforced resin composition

The invention provides a glass fiber reinforced resin composition, with features of excellent mechanical strength, small anisotropy of in-process shrinkage rate, good surface appearance and anti-flaming feature. The glass fiber reinforces resin composition comprises 0.1-10 wt% of poly- caprolactone (C component) relative to (A) 40-99 wt% of a thermosplastic resin (A component) and 1-60 wt% of a reinforced filling material (B component) and the (B) reinforced filling material (B component) comprises a flat cross-section glass fiber (B-1 component) wherein the average value of the long diameter of the fiber cross-section is 10-50 Mum and the average value of the ratio of the long diameter to the short diameter is 1.5-8 and a filling material (B-2 component) except the B-1 component and the weight ratio of the B-1 component to the B-2 component (B-1 component / B-2 component) is 5 / 95-100 / 0.

Owner:TEIJIN KASEK KK

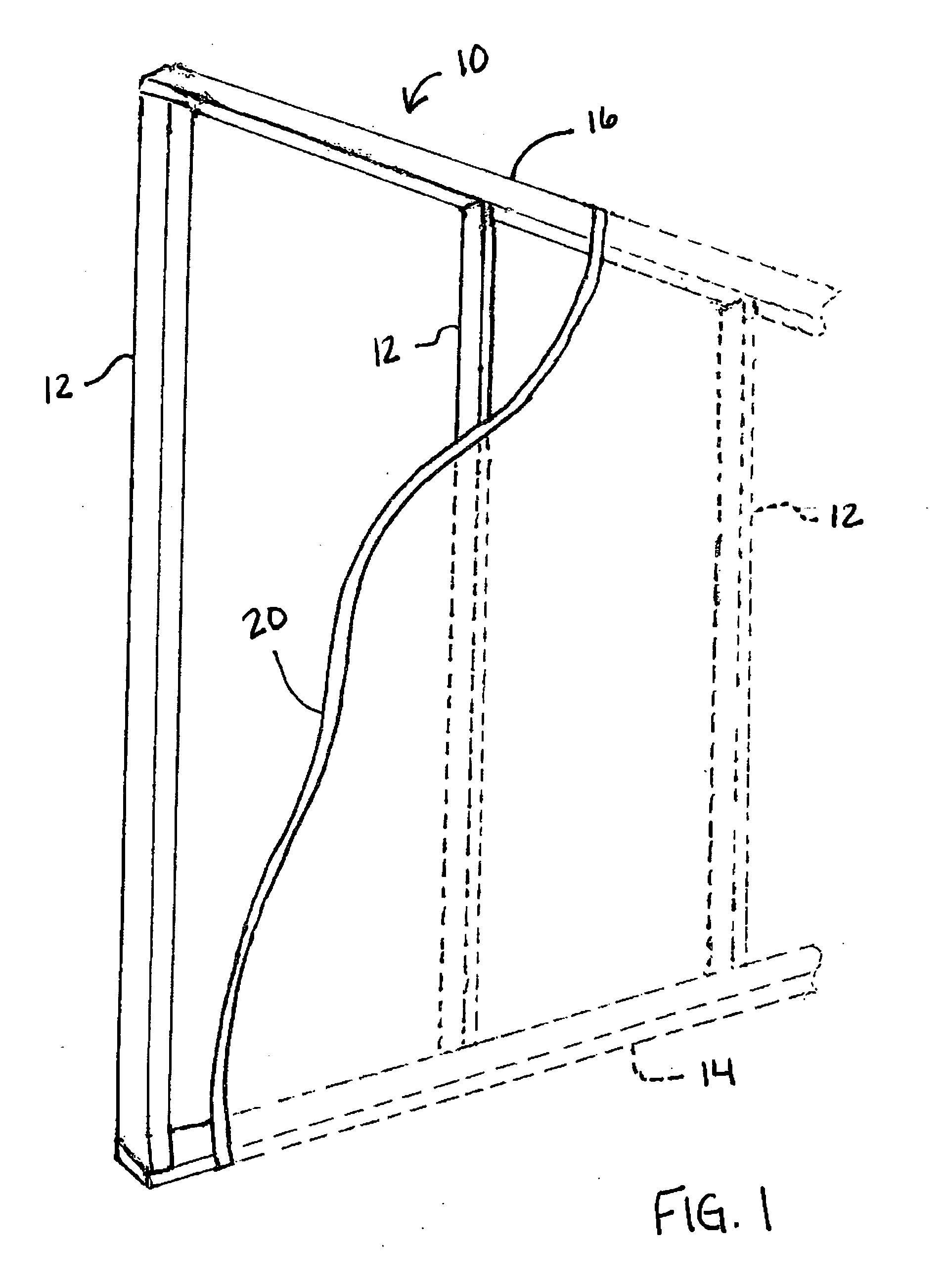

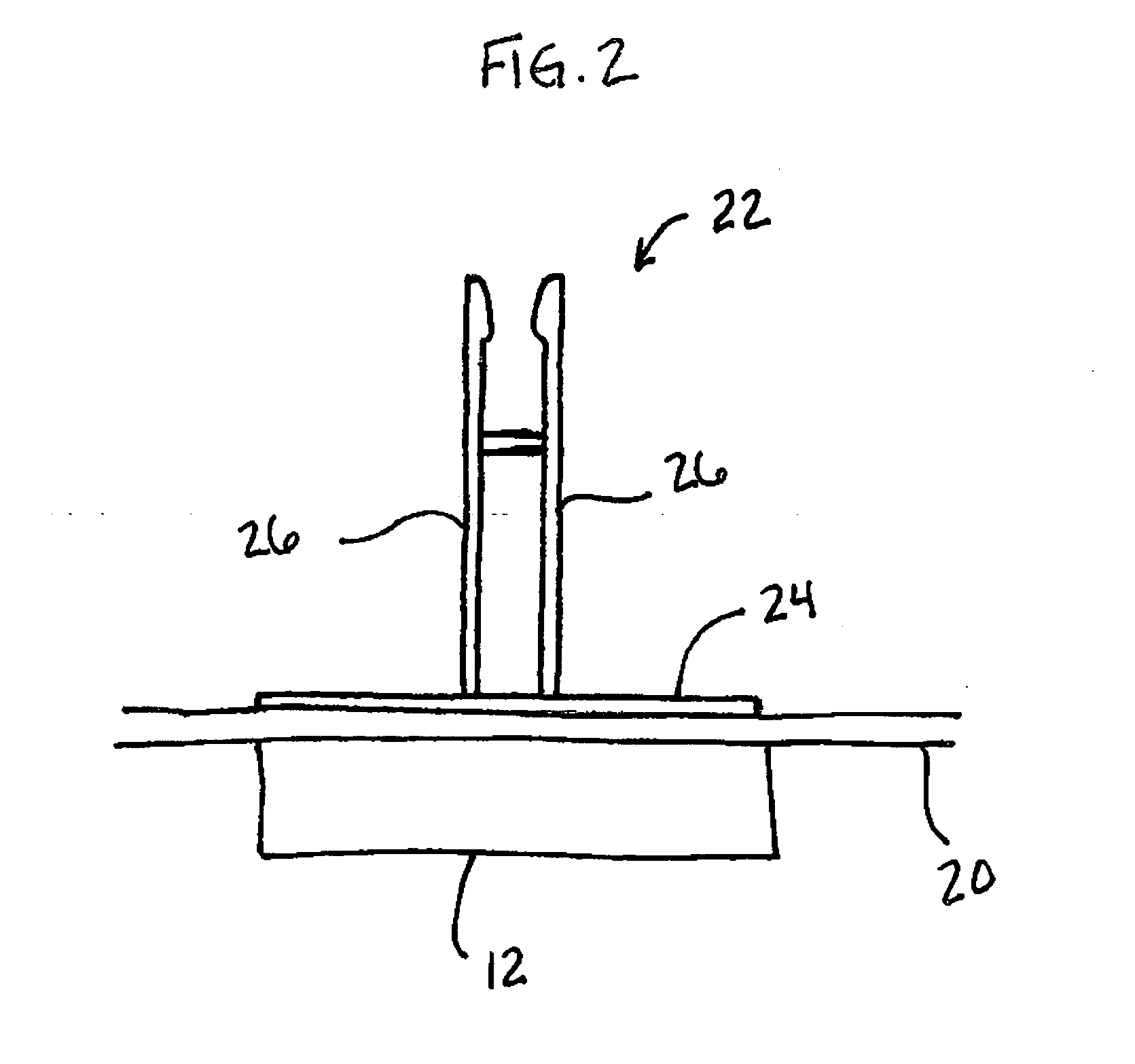

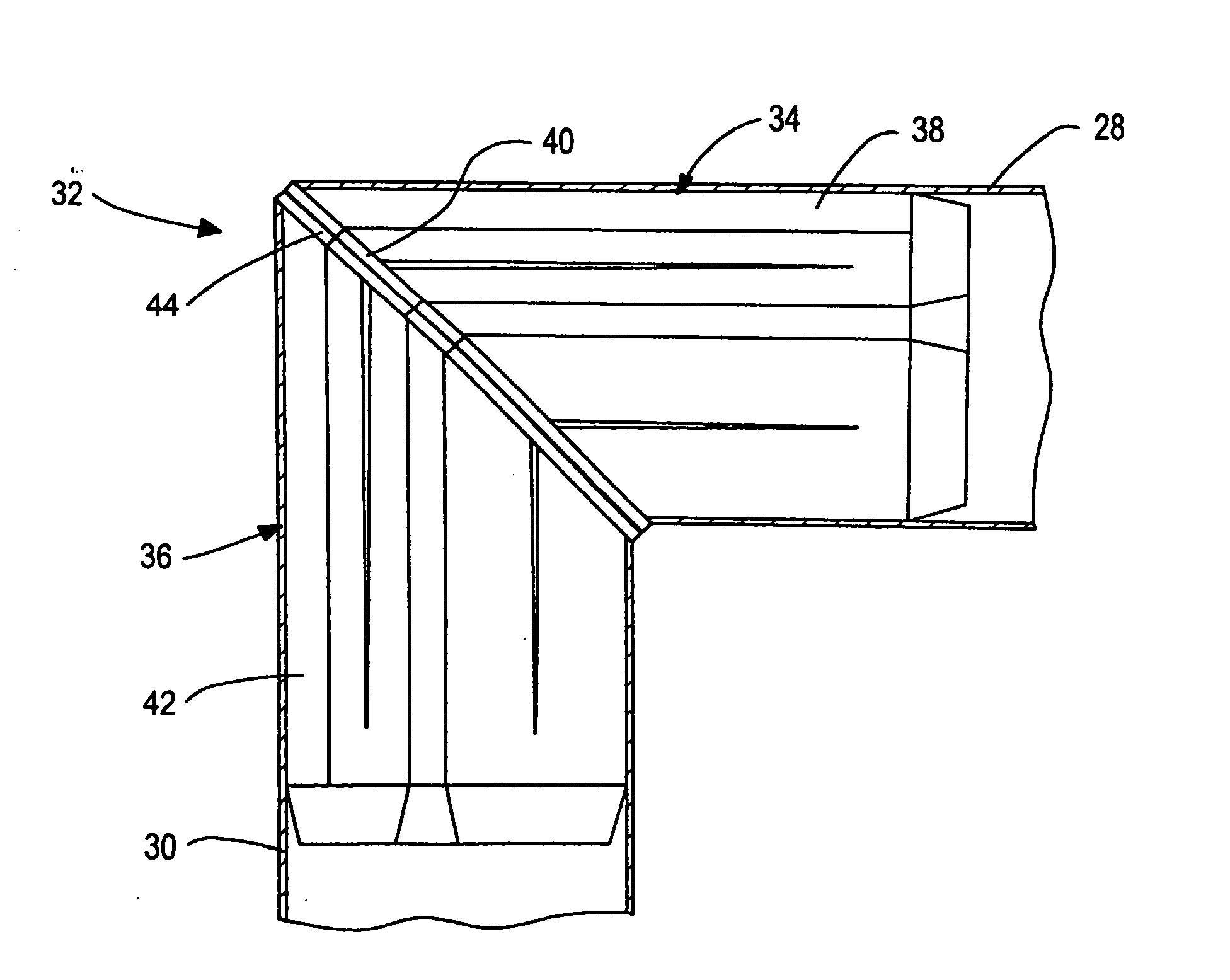

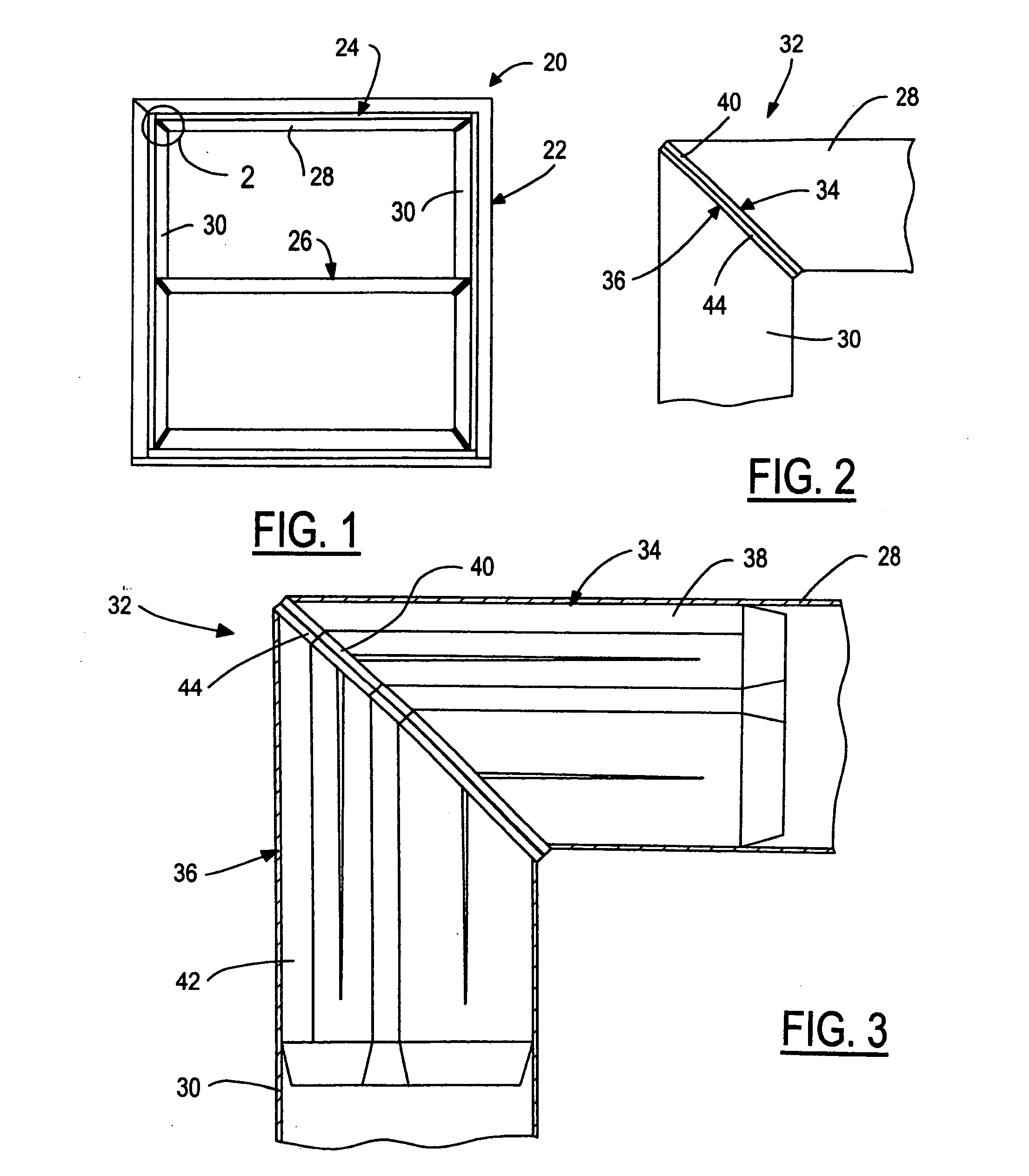

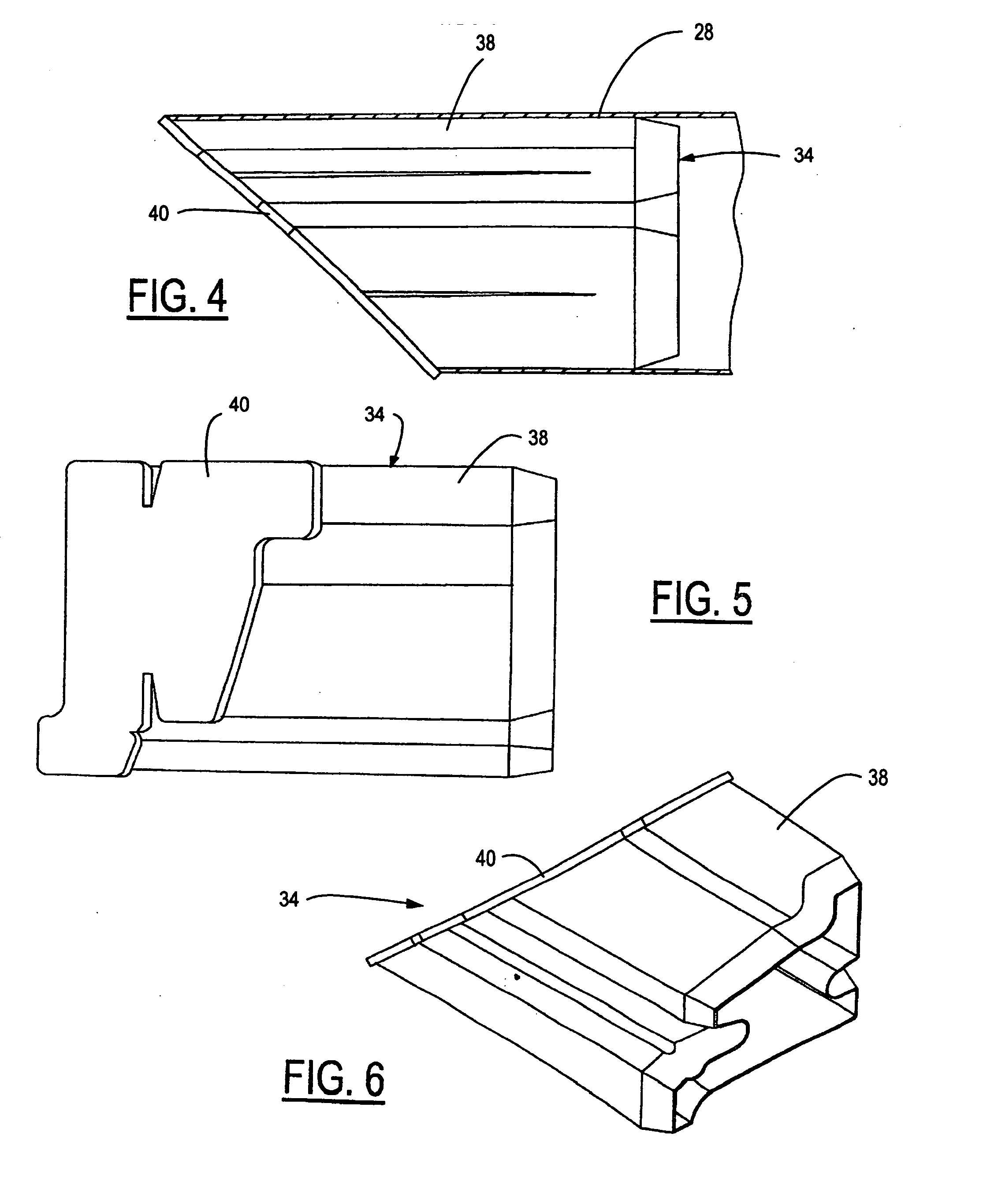

Framing corner joint and method of manufacture

InactiveUS20070245650A1Readily be welded to each otherIncrease costDoors/windowsPublic buildingsGlass fiberThermoplastic

A framing corner joint includes first and second framing rails of fiberglass-reinforced resin construction. The first and second framing rails have hollow mitered ends. A pair of thermoplastic plugs are received in the mitered ends of the respective framing rails. Each of the plugs includes a body inserted into the hollow interior of an associated framing rail and a flat plug flange at an angle of 45° to the body. The plug flanges extend outwardly from the peripheries of the bodies between the rail ends and have flat end faces that are bonded to each other. The bodies of the plugs preferably are hollow, and preferably are received by interference press-fit within the ends of the rails. The plug flanges of the plugs preferably are welded to each other.

Owner:MILGARD MFG INC

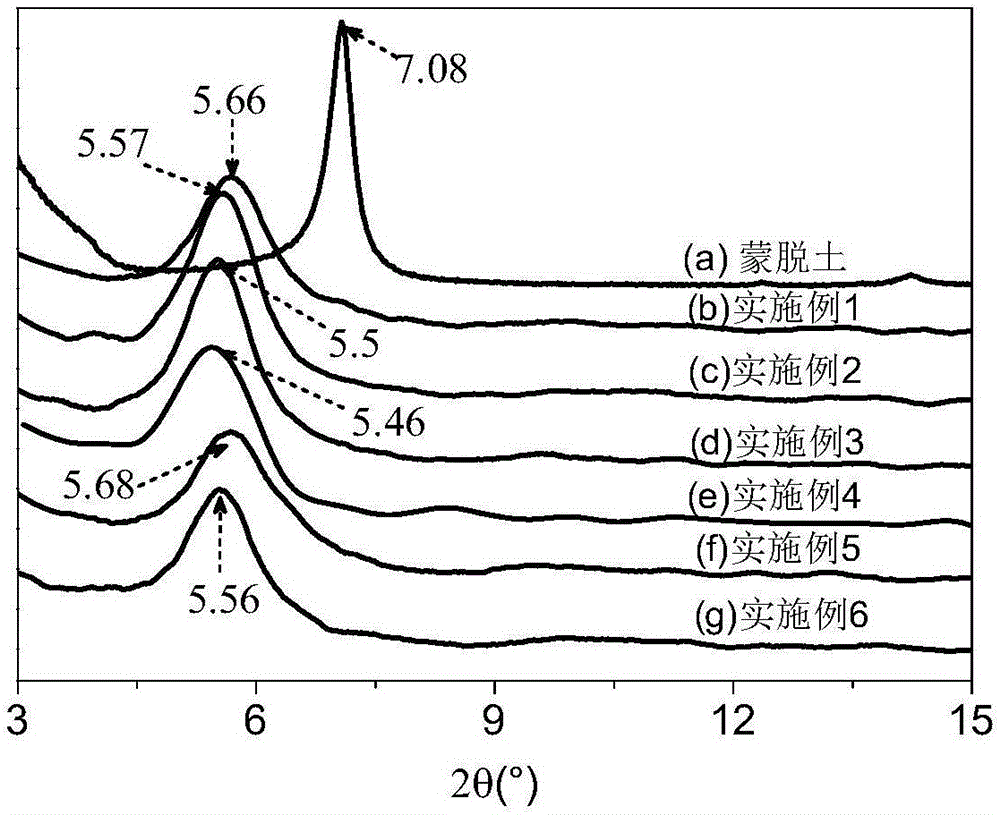

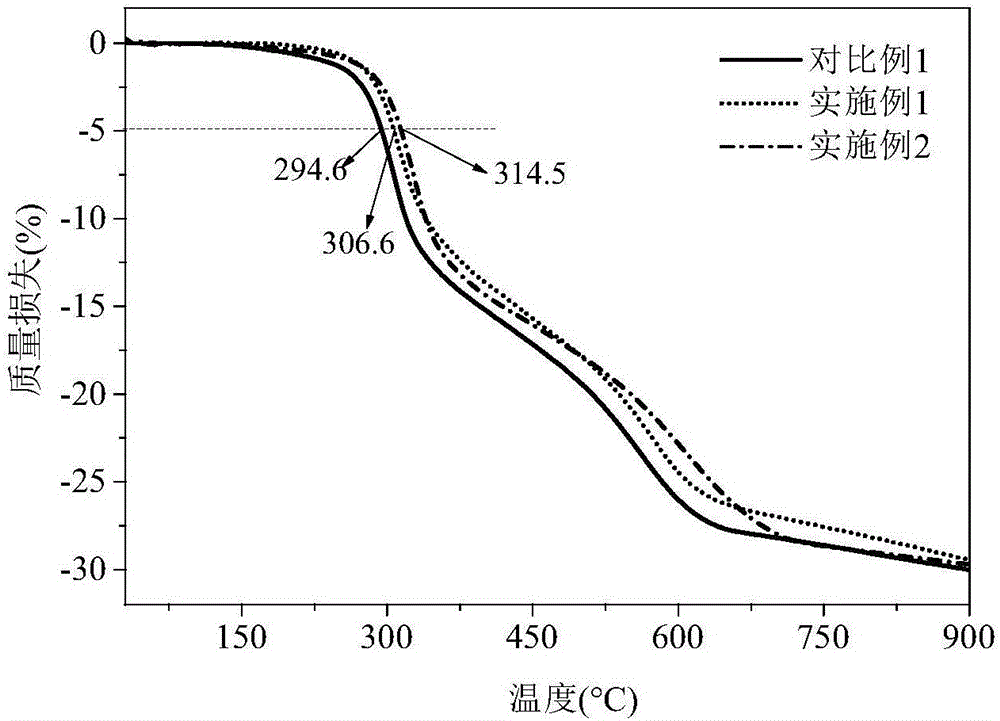

Preparation method of carbon nanotube-montmorillonoid self-assembled nano powder grafting glass fiber reinforced resin composite material

The invention discloses a preparation method of a carbon nanotube-montmorillonoid self-assembled nano powder grafting glass fiber reinforced resin composite material. The preparation method comprises the following steps: dispersing a carbon nanotube in aprotic solvent, modifying by virtue of organic amine, performing hydrochloric acid salt forming reaction, and obtaining carbon nanotube ammonium salt; ultrasonically dispersing the montmorillonoid and carbon nanotube ammonium salt in the water, filtering, repeatedly washing, spraying and drying to obtain carbon naontube-montmorillonoid self-assembled nano powder; ultrasonically dispersing the nano powder in a silane coupling agent solution, uniformly spraying on the surface of glass fibers, an vacuum drying to obtain nano powder grafting glass fiber prefabricated body; and compounding the prefabricated body with resin by virtue of a composite material forming process, thus obtaining the carbon nanotube-montmorillonoid self-assembled nano powder grafting glass fiber reinforced resin composite material. By adopting the preparation method, the dispersity of the carbon nanotube can be effectively improved, and the interlayer distance of the montmorillonoid can be increased; and the nano powder is grafted to the glass fibers, so that the dispersity in the composite material can be further improved, the interface adhesion between the resin and the fibers can be improved, and the mechanical performance and heat resistance of the fiber composite material can be improved.

Owner:HOHAI UNIV

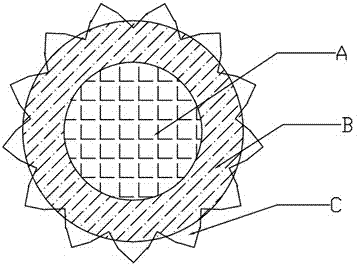

Hybrid basalt fiber and glass fiber reinforced resin

ActiveCN104725780AIncreased tensile modulus of elasticityIncrease elasticityGlass fiberUltimate tensile strength

The invention discloses a hybrid basalt fiber and glass fiber reinforced resin which comprises glass fiber, basalt fiber and a resin, wherein the glass fiber and the basalt fiber are solidified by the resin, and the basalt fiber wraps the outer side of the glass fiber. The elastic tensile modulus and shear strength of the hybrid basalt fiber and glass fiber reinforced resin disclosed by the invention are significantly increased, and the excellent alkali resistance, tensile strength higher than that of the glass fiber, and elasticity modulus of the basalt fiber are fully used, so that the tensile strength, elasticity modulus and durability of a hybrid fiber reinforcement disclosed by the invention are improved under the condition that few cost is increased, and therefore, FRP (fiber reinforce plastic) reinforcements have the opportunity to be applied to more occasions.

Owner:HOHAI UNIV +1

Composite steel tube used for oil and gas conveying pipeline and externally wound by glass fiber resin reinforcing protective layer

InactiveCN104197114AImprove pressure bearing capacityImprove aging resistanceCoatingsRigid pipesGlass fiberPhysical chemistry

The invention relates to a composite steel tube used for an oil and gas conveying pipeline and externally wound by a glass fiber resin reinforcing protective layer. A traditional pipeline steel tube is taken as a base tube, high-strength glass fibers infiltrated with resin are wound around the outer surface of the pipeline steel base tube and serve as the high-strength glass fiber reinforcing resin layer, and therefore the brand new composite tube is formed, wherein the inner layer of the composite tube is pipeline steel, and the outer layer of the composite tube is glass-reinforced plastic. The composite tube has the performance characteristics of the pipeline steel tube and a glass reinforced plastic tube, the pressure bearing capacity and the crack arrest capacity of the pipeline are improved, the defect that a high-strength pipeline is poor in tenacity is overcome, 3PE outer corrosion prevention of a traditional pipeline is replaced, the corrosion-resistant and ageing-resistant capacity of the pipeline are improved, and in comparison with a 100% pipeline steel tube with the same pressure bearing capacity, the manufacturing cost of the composite steel tube is reduced by about 20%. The composite steel tube can be used and popularized in construction projects of long-distance petroleum and gas conveying pipelines.

Owner:CNPC BOHAI EQUIP MFG +1

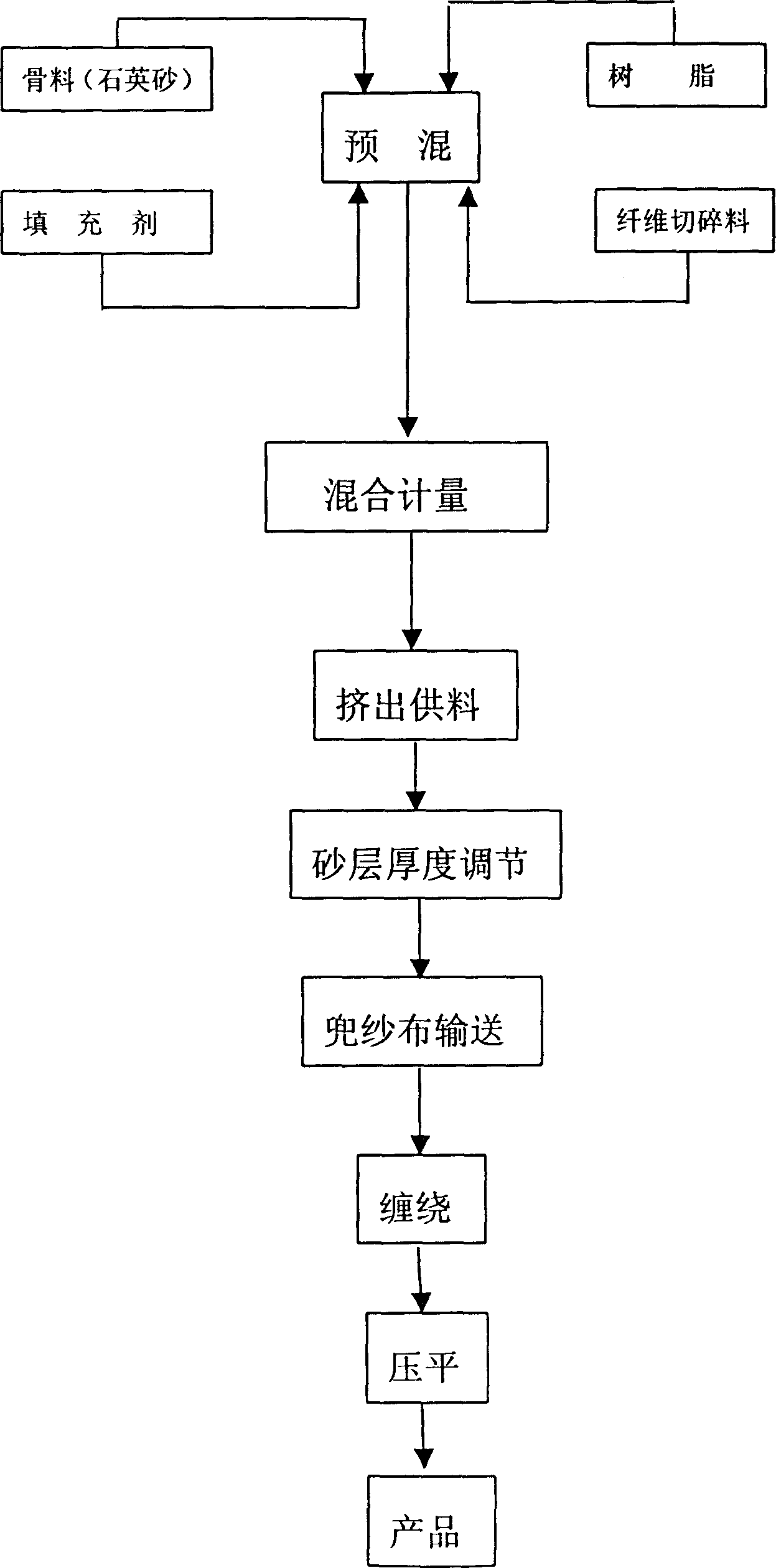

Staple glass fiber reinforced resin concrete pipeline production method and equipment

InactiveCN1709672ADimensionally stable sectionReduce pollutionMixing operation control apparatusGlass fiberFiber

A method for producing a pipeline of glass fibre reinforced concrete, it also provides its device. It consists of the steps: put the quartzite of framework material and fill material in the beater to whisk, at the period of whisking, add fibre material cut up and colophony, mix the fore related material together completely; and then extrude the mixture quantificationally of by screw, and then transport the mixture extruded by gauze, and then intertwist and planish it. In this process, content of silicon dioxide of framework quartzite exceed 98%, which has less water content of 0.2%, specific gravity is 1.60-1.65Kg / cm3; fill material is powder of CaCO3, SiO2 or the in the cutting process of pipe produce. The fill material is 5-10% the quantity of colophony concrete; fibre material cut up is 1-3%; there is seriate device of fibre cutting; there is rate accommodate device of quartzite outer which can be disassembled in the exit of extrude.

Owner:上海耀华玻璃钢有限公司

Sound attenuating fencing assembly

InactiveUS7314212B2Prevent movementEasy to manufactureCeilingsNoise reduction constructionAccessory structureGlass fiber

A deformation and weather resistant, noise attenuating fencing assembly comprises a series of hollow posts, each post formed of a fiberglass reinforced resin, having spaced apart load bearing walls defining an exterior surface, an interior surface, a first open end and a second open end. The structure-reinforcing cap is inserted within a first open end of each of the posts and frictionally engages the interior surface of the post to substantially prevent movement of the exterior surface thereof when various types of appurtenant structures are mounted thereon, which would otherwise cause deformation and possible structural failure of the post walls. First and second clips are inserted into the first and second open ends of the post, respectively, to provide an easy mechanism to properly space and secure the posts together.

Owner:HIGGINS WILLIAM RAY

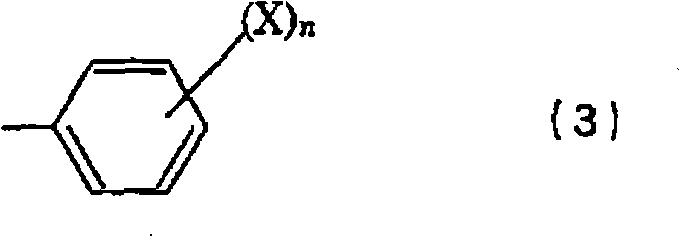

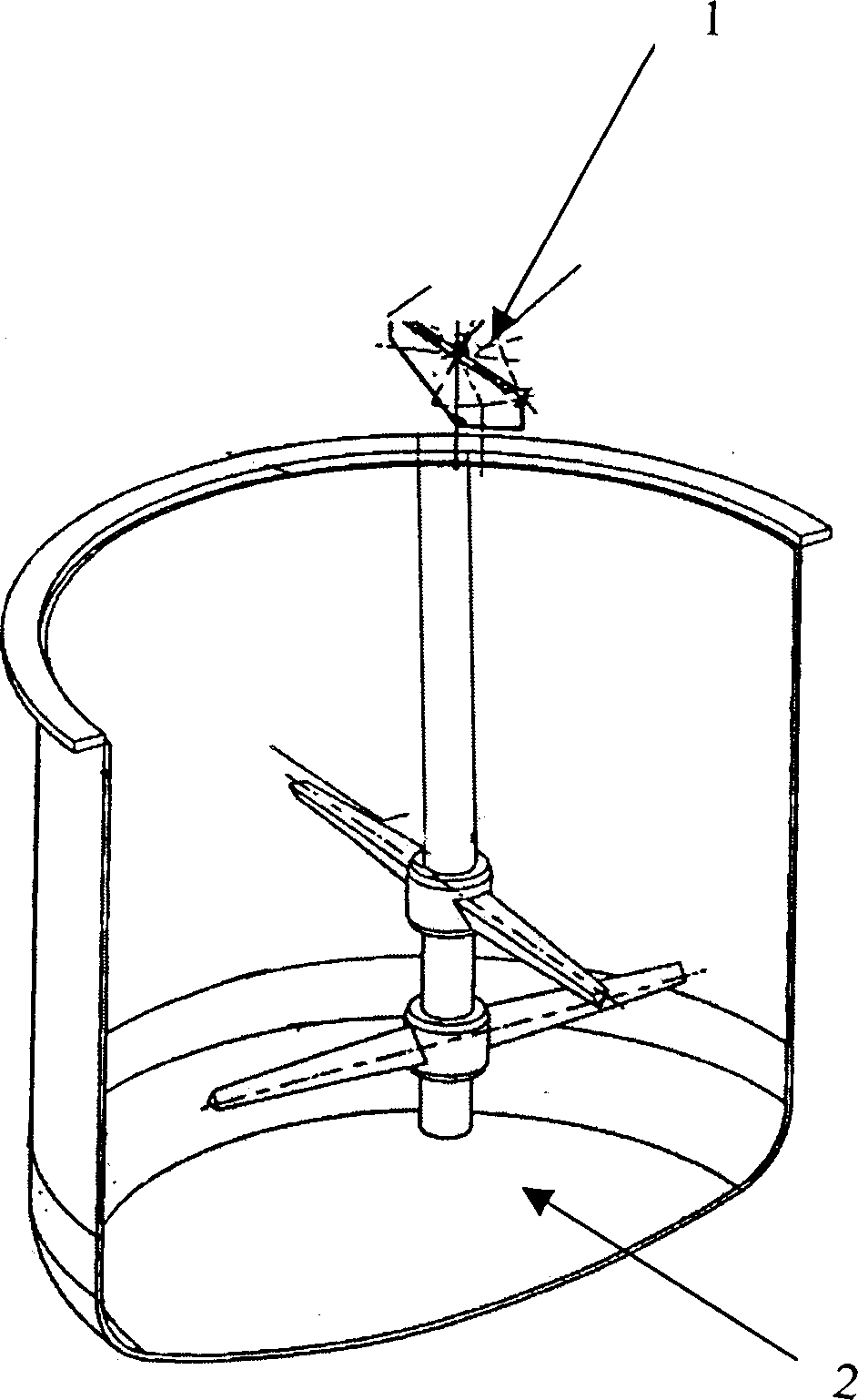

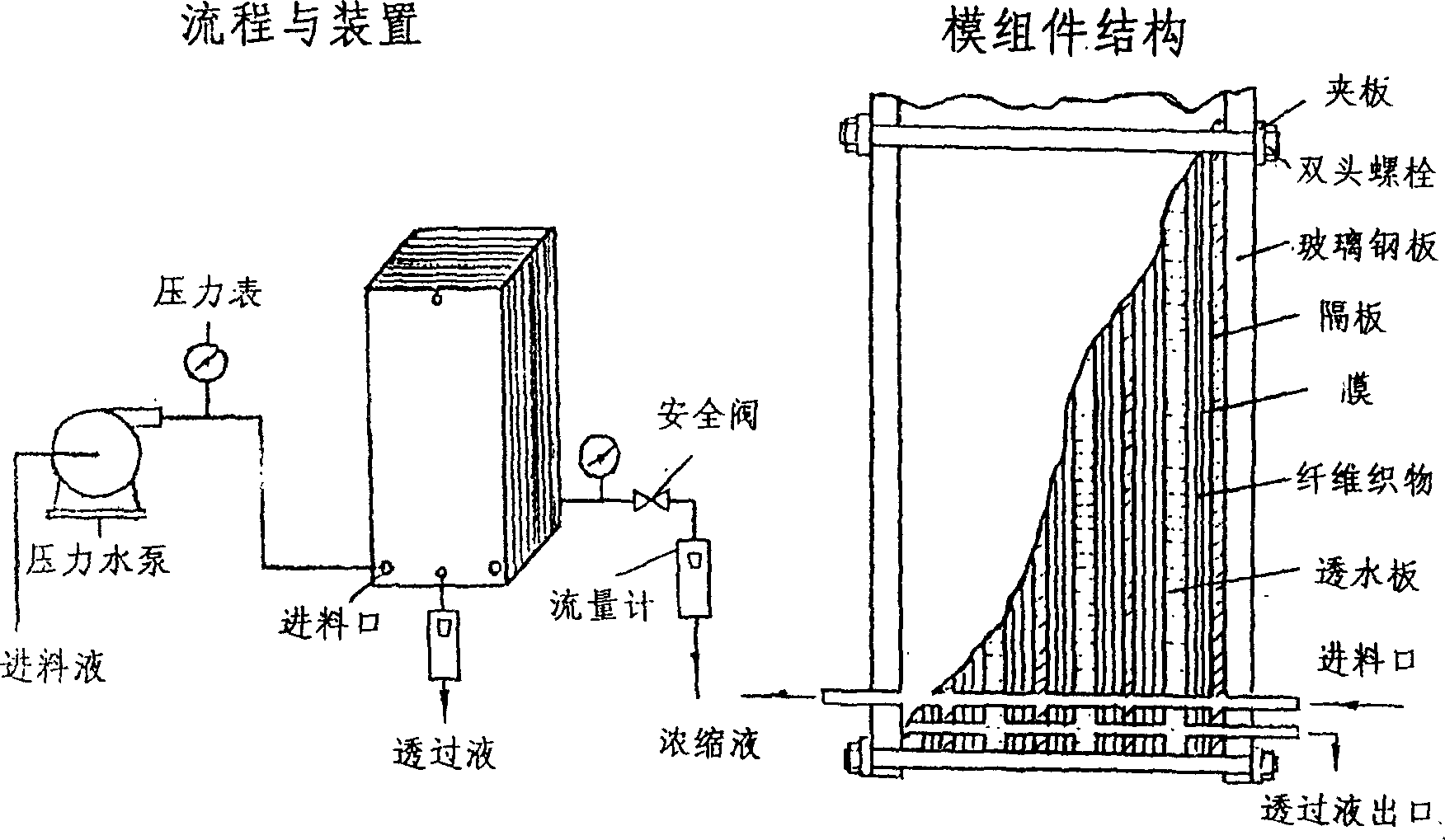

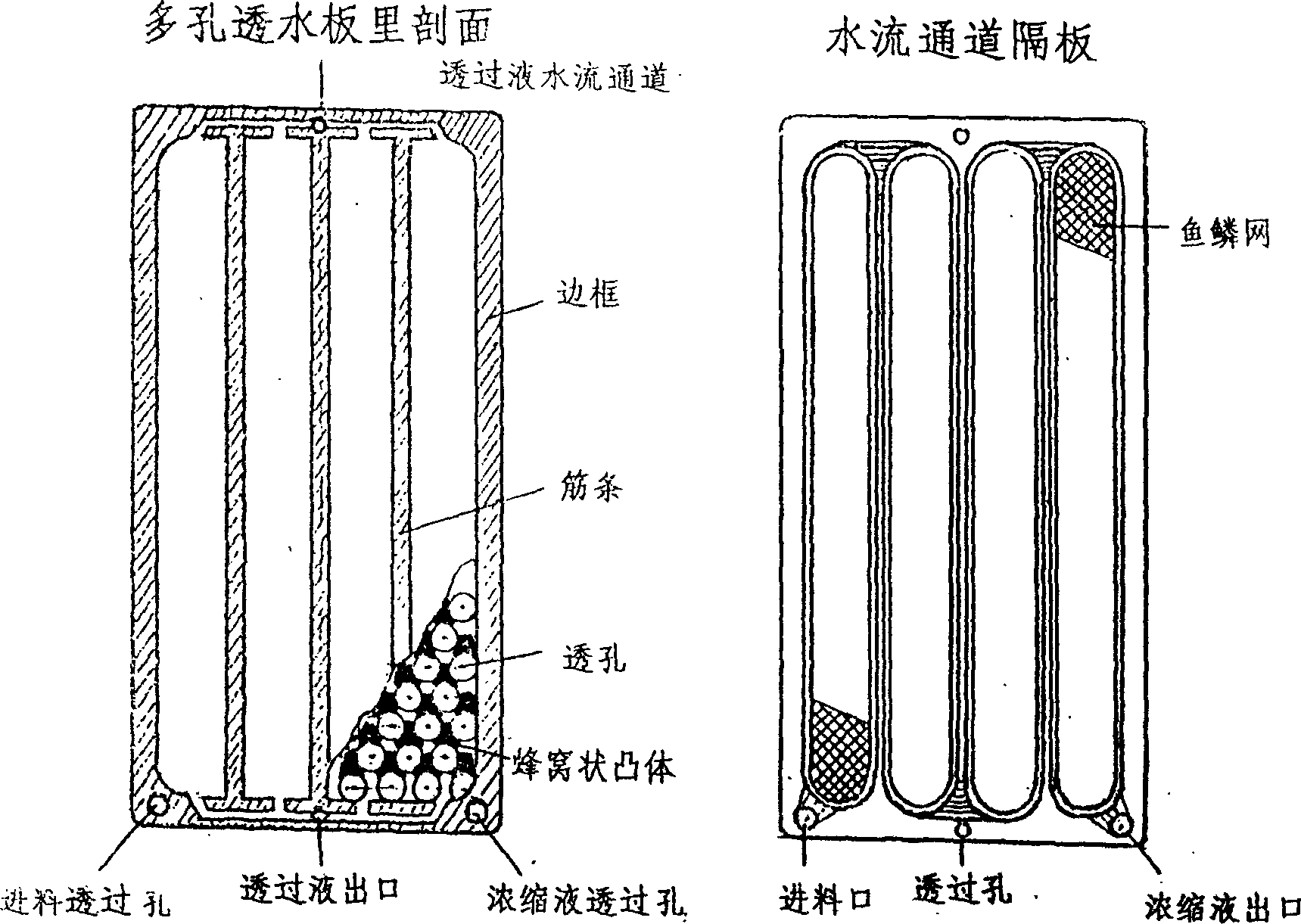

New pattern board-frame structure ultra-filter and reverse osmosis device used in cleanly production

InactiveCN1485124AReduce manufacturing costSimple structureUltrafiltrationReverse osmosisGlass fiberHigh density

A CLB-X super filter and a FSB-X reverse osmosis device for clean production. A porous board formed by die pressing glass-fibre strengthened resin, synthetic fiber fabric, membrane and a baffle of water paths are superposed to fasten bolt and compose the rectangular super filter and the reverse osmosis device. Although it is similar to the regular frame in assembly, the new water processing device has a stable configuration and a high-density surface area, can endure high pressure. For the water flow state, the device could effectively prevent film pollution, improve the water flux. It simplifies the configuration of membrane units and processing, thus saves production cost. The flow of super filter (reverse osmosis) and membrane units of the invention are seen the drawing of the abstract.

Owner:徐守才 +1

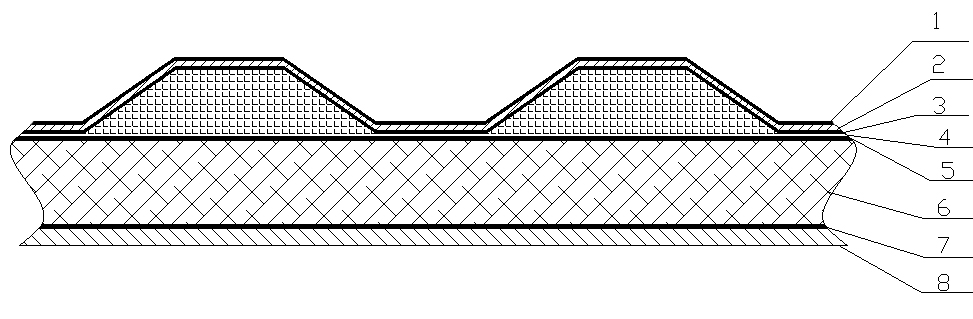

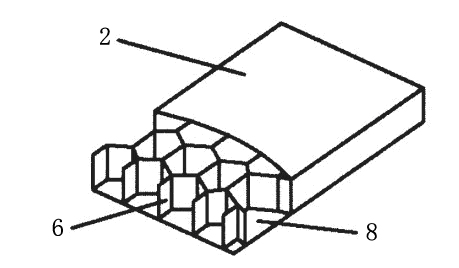

Composite board and application thereof as composite material for fireworks and crackers transport vehicle carriage

InactiveCN102029747AHigh strengthHigh modulusSynthetic resin layered productsGlass/slag layered productsAdhesive cementFiber

The invention provides a composite board and application thereof as a composite material for a fireworks and crackers transport vehicle carriage. The composted board proved by the invention comprises an armor plate, a polymer cellular material layer, a glass fiber reinforcement resin composite layer and an electric-conduction elastic alloy layer. The armor plate and the polymer cellular material layer can be bonded together with unsaturated polyester resin doped with reinforced fibers. The polymer cellular material layer and the glass fiber reinforcement resin composite layer can be bonded together with a polyurethane adhesive. The glass fiber reinforcement resin composite layer and the electric-conduction elastic alloy layer can be bonded together with polyamide viscoelastic resin. The composite board provided by the invention has the characteristics of light weight and high strength and multiple functions of retarding flames, insulating heat, attenuating the vibration of explosive blasts, conducting and dissipating static electricity and preventing radio frequency. The fireworks and crackers transport vehicle carriage made of the composite boards can sufficiently guarantee the transportation safety of explosives, such as fireworks, crackers and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

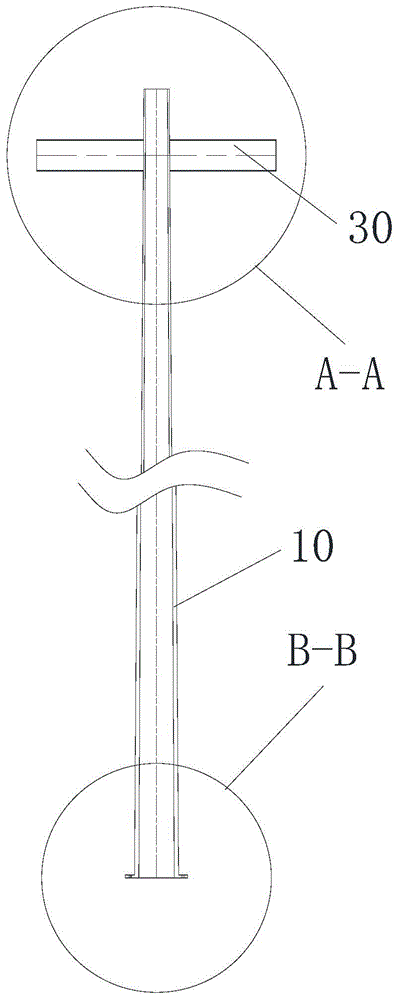

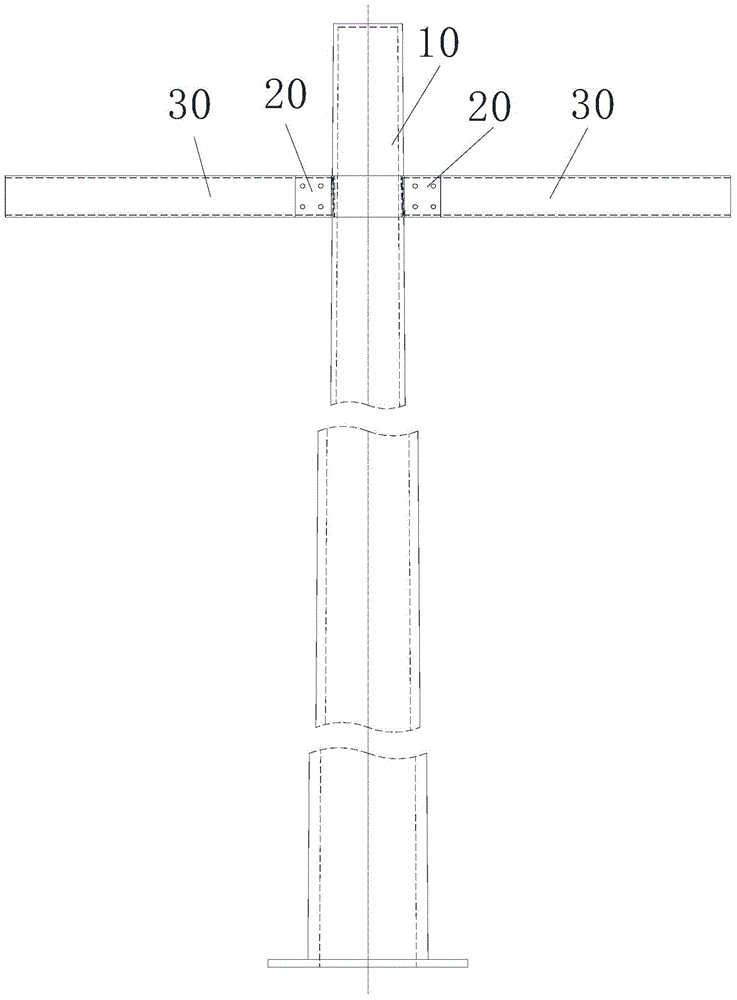

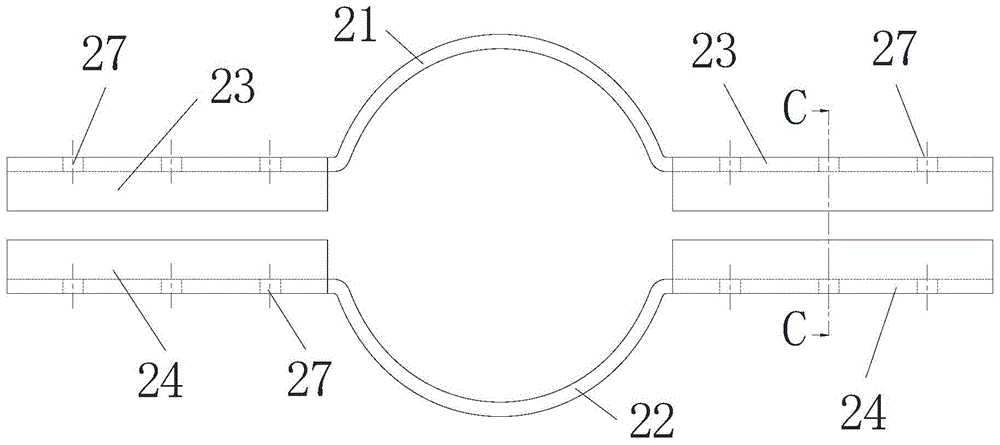

Transmission tower

The invention provides a transmission tower. The transmission tower comprises a supporting rod body and a cross arm, wherein the supporting rod body is made of glass fiber reinforced resin matrix composites, and the cross arm is connected with the supporting rod body. According to the transmission tower, the supporting rod body is made of the glass fiber reinforced resin matrix composites, and therefore the transmission tower has the advantages of being high in strength, low in weight, resistant to abrasion and fatigue and capable of effectively solving the technical problem that an existing transmission tower is difficult to transport, install and maintain in a mountain area zone because a supporting rod body is heavy.

Owner:STATE GRID CORP OF CHINA +1

Glass fiber-reinforced resin molded article

Provided is a glass fiber-reinforced resin molded article having high tensile strength and high impact strength in combination with a low dielectric constant and a low dissipation factor. The glass fiber-reinforced resin molded article contains: 10 to 90 mass % of a glass fiber; and 90 to 10 mass % of a resin based on the total amount of the glass fiber-reinforced resin molded article, wherein the glass fiber has composition containing: 52.0 to 57.0 mass % of SiO2; 13.0 to 17.0 mass % of Al2O3; 15.0 to 21.5 mass % of B2O3; 2.0 to 6.0 mass % of MgO; 2.0 to 6.0 mass % of CaO; 1.0 to 4.0 mass % of TiO2; and less than 1.5 mass % of F2, and the total amount of Li2O, Na2O, and K2O is less than 0.6 mass %, based on the total amount of the glass fiber, and the glass fiber has a number-average fiber length of 30 to 5000 μm.

Owner:NITTO BOSEIKI CO LTD

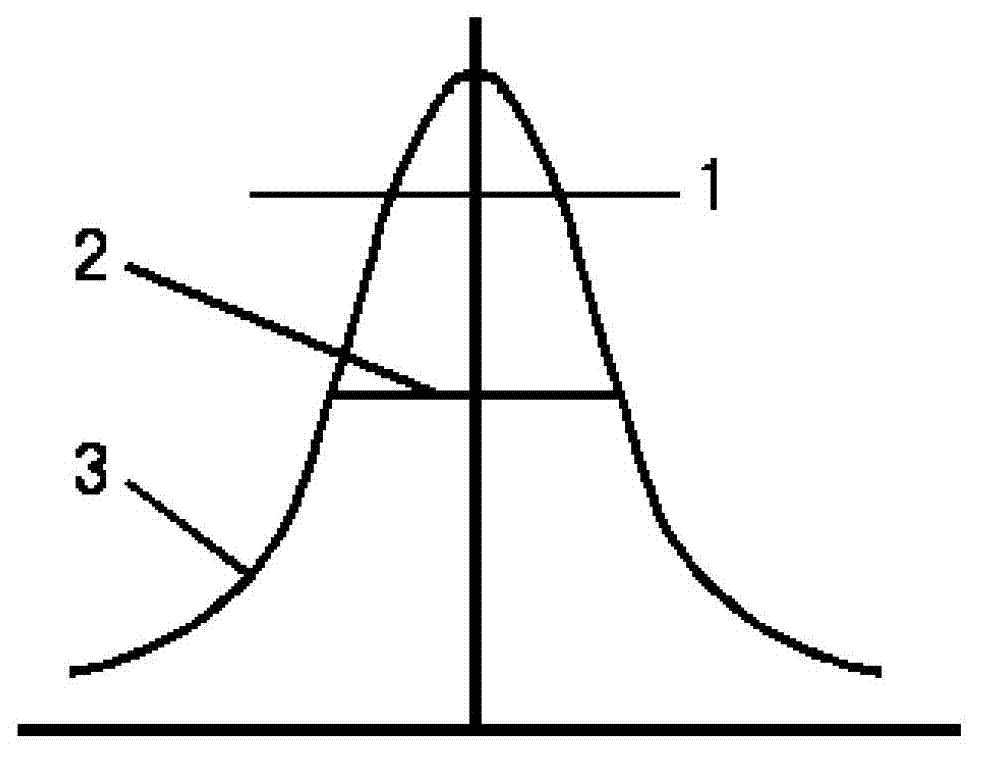

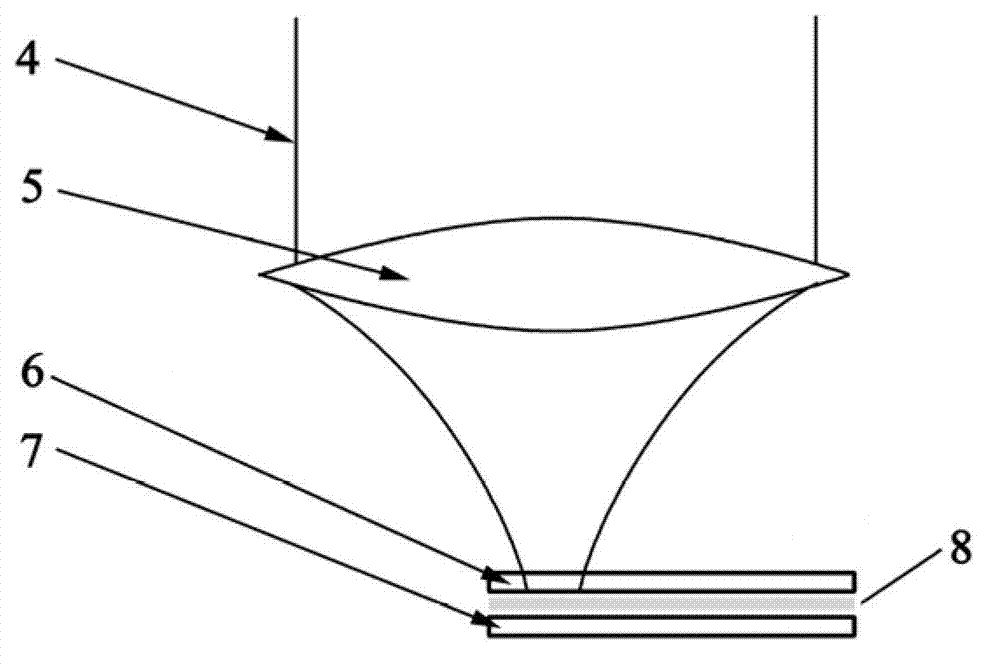

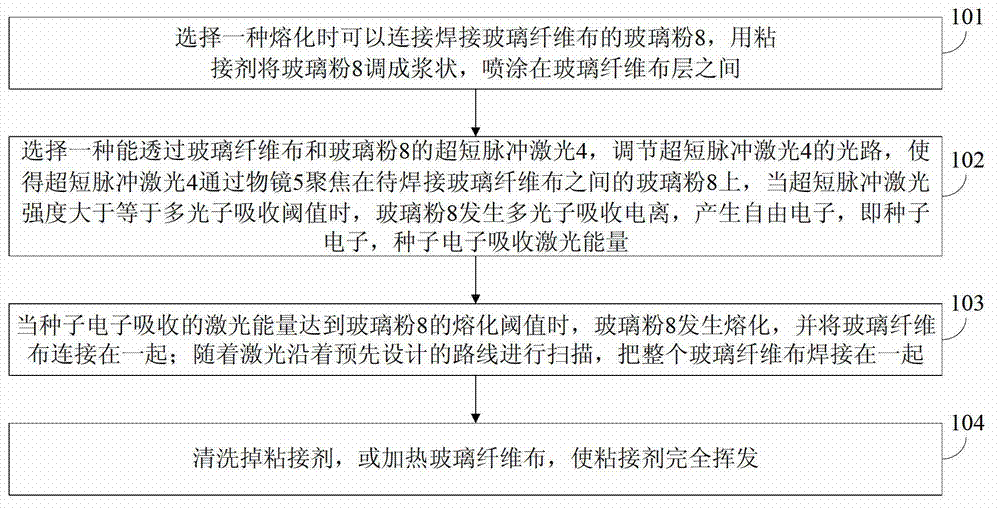

Method for welding glass fiber cloth

The invention discloses a method for welding glass fiber cloth. The method comprises the following steps of: mixing glass powder into slurry, and coating the slurry between glass fiber cloth layers; adjusting a light path of ultra-short pulse laser so as to focus the ultra-short pulse laser on the glass powder between the glass fiber cloth to be welded through an objective lens; when the intensity of the ultra-short pulse laser is greater than or equal to a multi-photon absorption threshold value, and generating multi-photon absorption and ionization by the glass powder to produce seed electrons capable of absorbing laser energy; when the laser energy absorbed by the seed electrons is equal to a smelting threshold value of the glass powder, smelting the glass powder, and connecting the glass fiber cloth with the glass powder; and scanning by the ultra-short pulse laser along a pre-designed line, and welding the whole glass fiber cloth. By the method, the mechanical property of a composite material is improved; the method is suitable for automatic production; the mechanical property of a glass fiber enhanced resin-based composite material is improved; a layering phenomenon is avoided; and layering of a bidimensional laminated structure and connection of a three-dimensional prefabricated piece are realized.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com