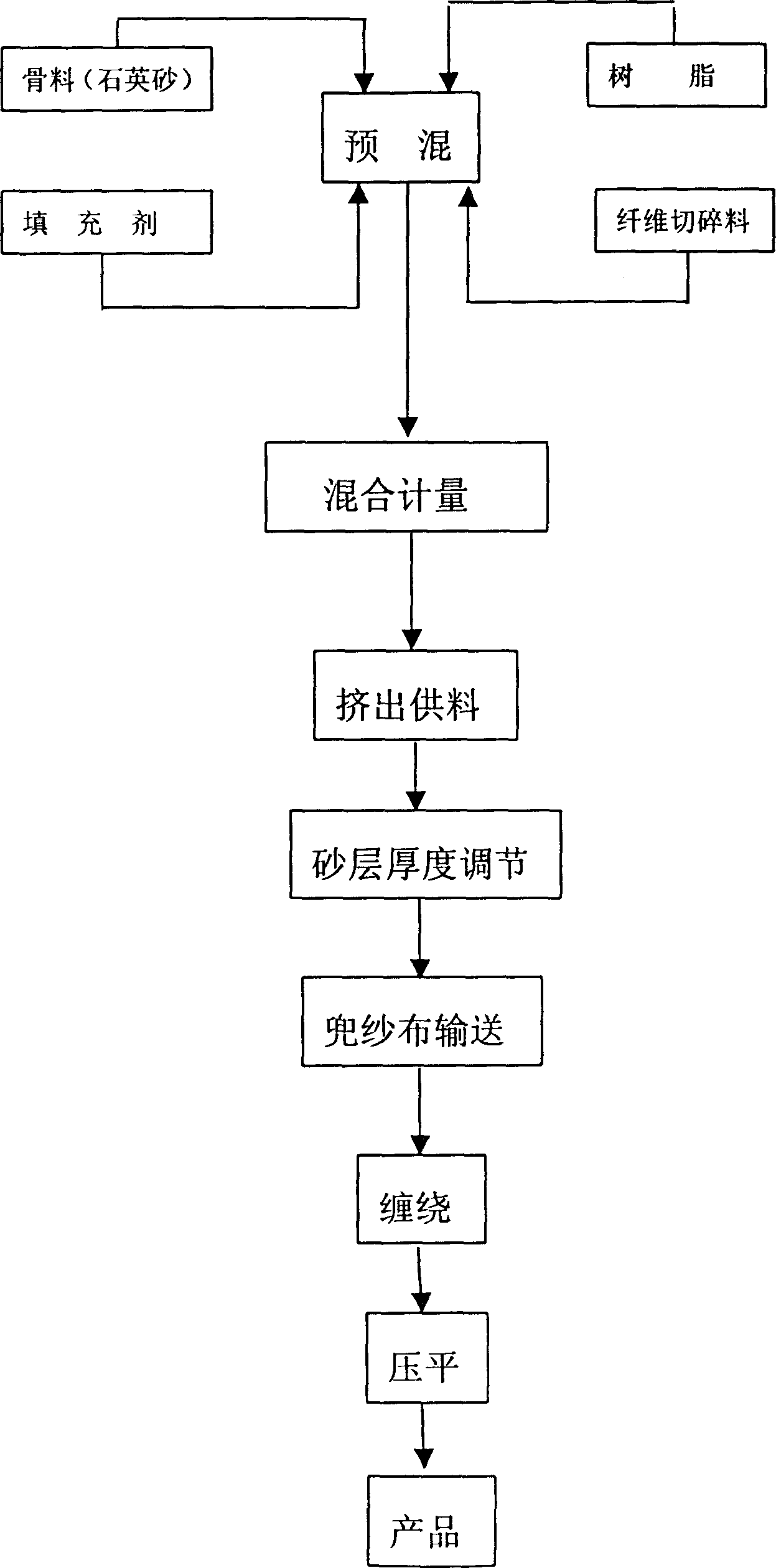

Staple glass fiber reinforced resin concrete pipeline production method and equipment

A technology of fixed-length glass fiber and resin concrete, applied in clay preparation equipment, chemical instruments and methods, mixing operation control, etc., can solve problems affecting product performance indicators, high equipment operating costs, low production efficiency, etc., and achieve guaranteed density , improve quality and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Taking the production of pipes above φ1500 (inclusive) as an example, the quartz sand gradation scheme is as follows: 10 mesh 5-10%, 20 mesh 25-30%, 30 mesh 14-20%, 50 mesh 26-30% , 5-8% for 60 mesh, 3% for 80 mesh. Calcium carbonate powder with a particle size of 1.0 μm is selected as the filling material, and 2.1% continuous untwisted fiber chopped material is added to the mixture.

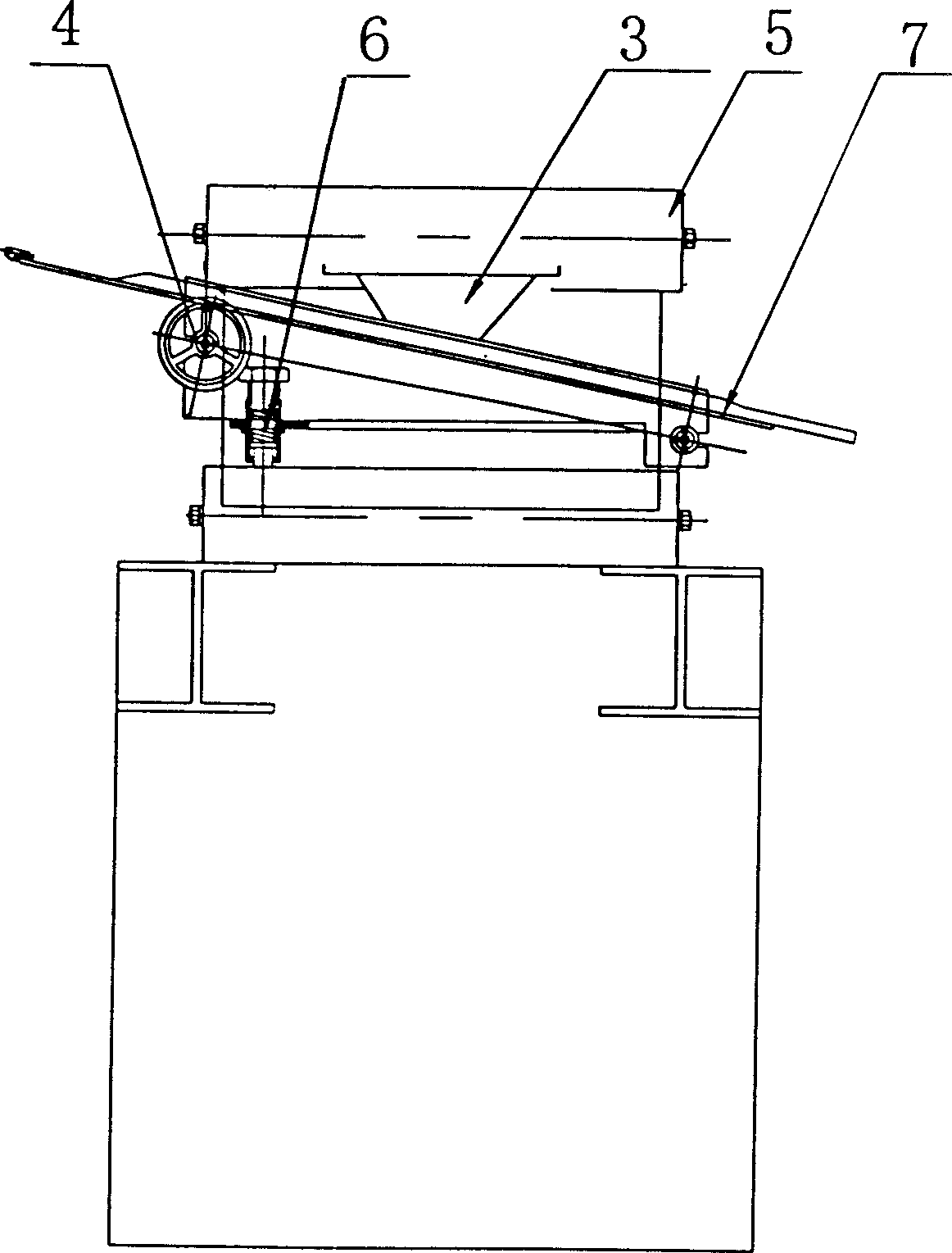

[0038] After adding 13.4% of the total amount of resin and fully stirring in the mixer, the mixed resin concrete is added to the screw extrusion device, and the resin curing agent is simultaneously input into the extrusion screw through the input pipe, and it is fully mixed with the resin concrete through the rotation of the screw. Mixing, the thickness adjustment device at the outlet ensures accurate adjustment of the sand thickness.

Embodiment 2

[0039] Example 2: For the production of φ800-φ1500, adjust the gradation scheme of quartz sand to: 10 mesh 5%, 20 mesh to 30 mesh 25 to 35%, 50 mesh to 60 mesh 55 to 65%, 80 mesh 0.5%; select 0.8 The calcium carbonate powder of μm particle diameter is filler material, adds 1.8-2.0% continuous untwisted fiber chopped material in the mixture simultaneously, and all the other are the same as embodiment 1.

Embodiment 3

[0040] Example 3: To produce φ800, adjust the quartz sand gradation scheme to: 20 mesh 5%, 30 mesh 16-27%, 40 mesh 23-27%, 50 mesh 21-30%, 60 mesh 7-12%, 80 mesh 5%. Calcium carbonate powder with a particle size of 0.5-0.7 μm is selected as the filling material, and 1.5-2.8% of continuous untwisted fiber chopped material is added to the mixture. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com