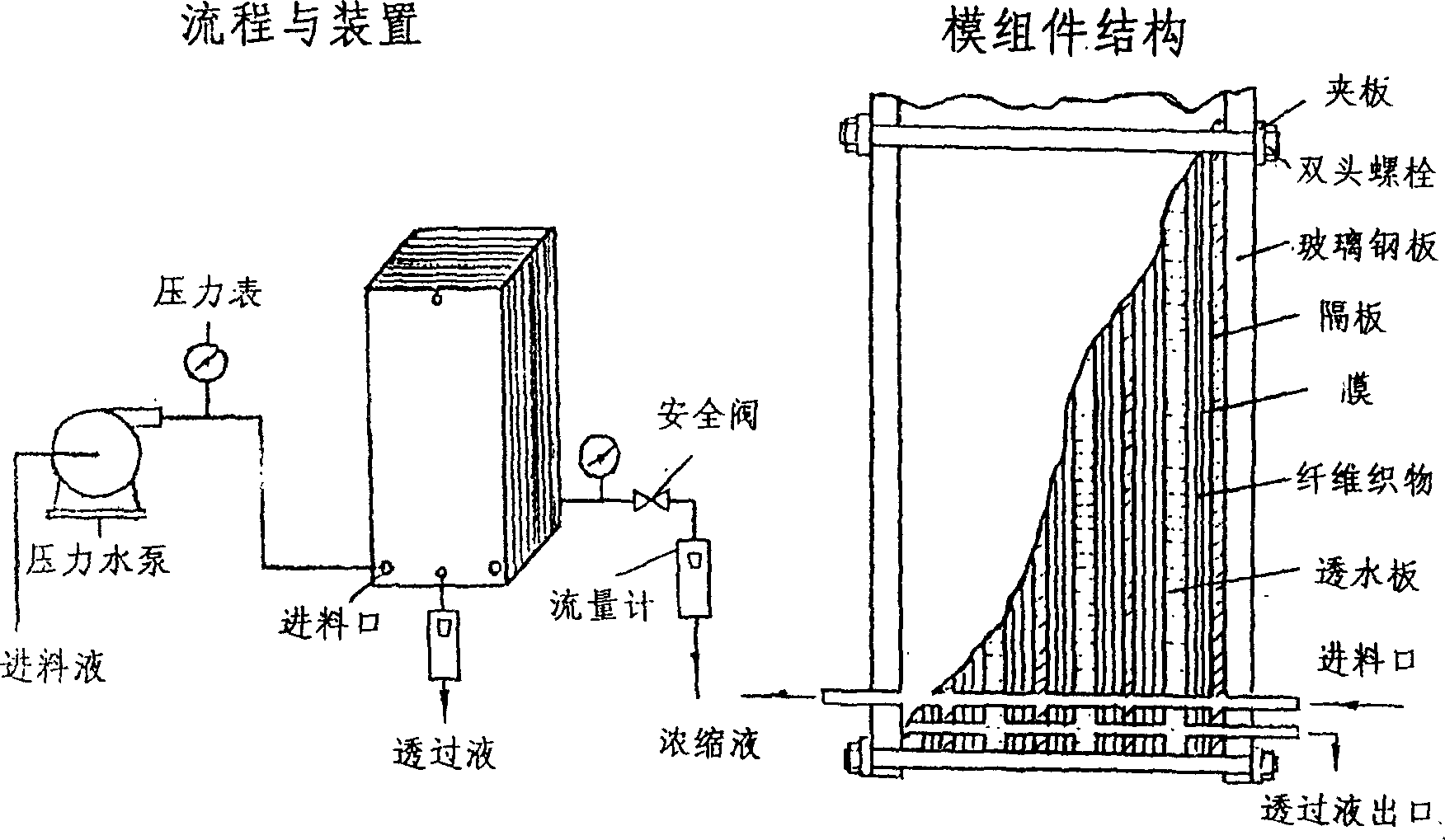

New pattern board-frame structure ultra-filter and reverse osmosis device used in cleanly production

A reverse osmosis device and clean production technology, applied in the direction of ultrafiltration, reverse osmosis, etc., can solve the problems of not being widely used, complex manufacturing process, high production cost, etc., achieve good practical performance, overcome low recovery rate, improve The effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

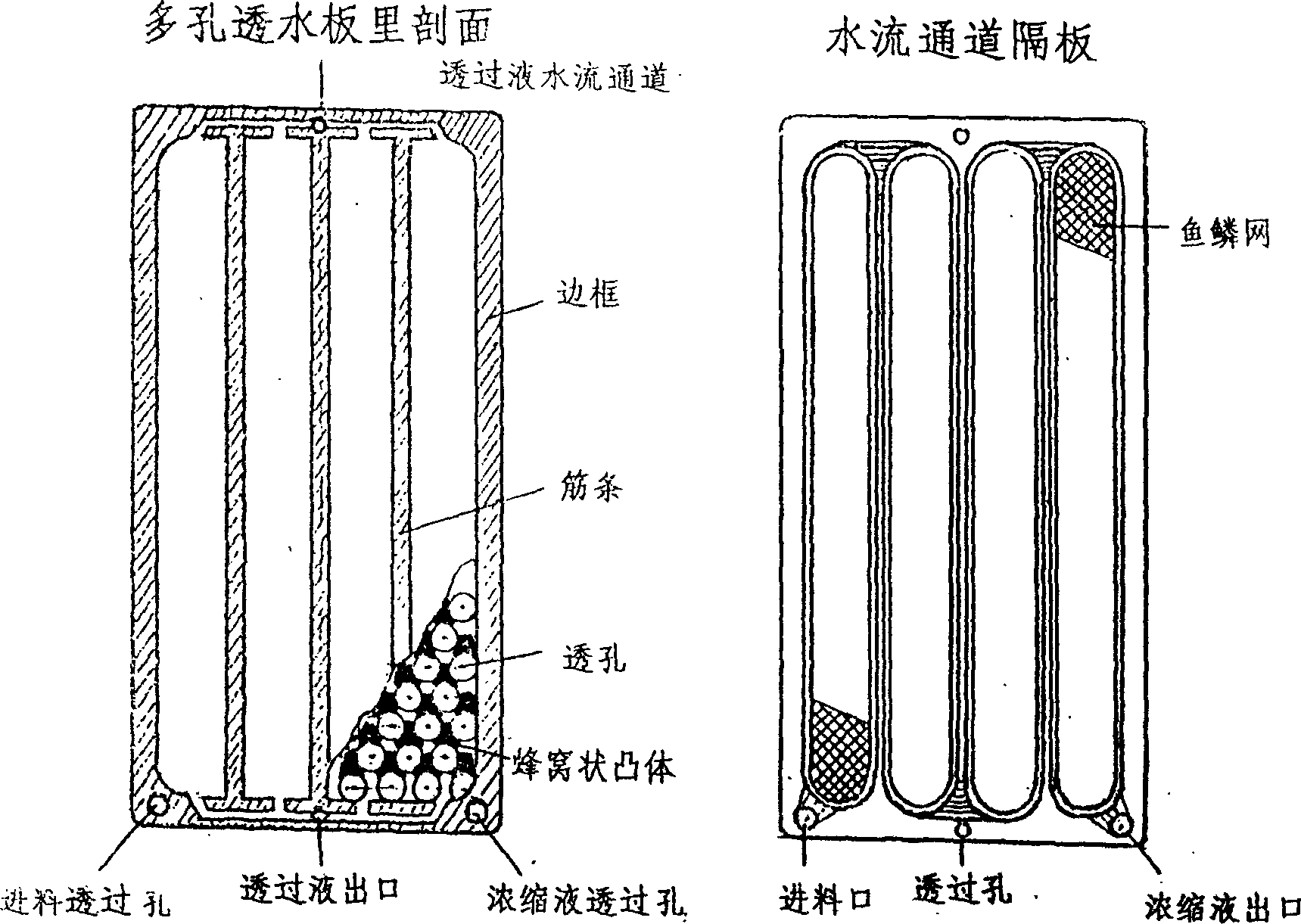

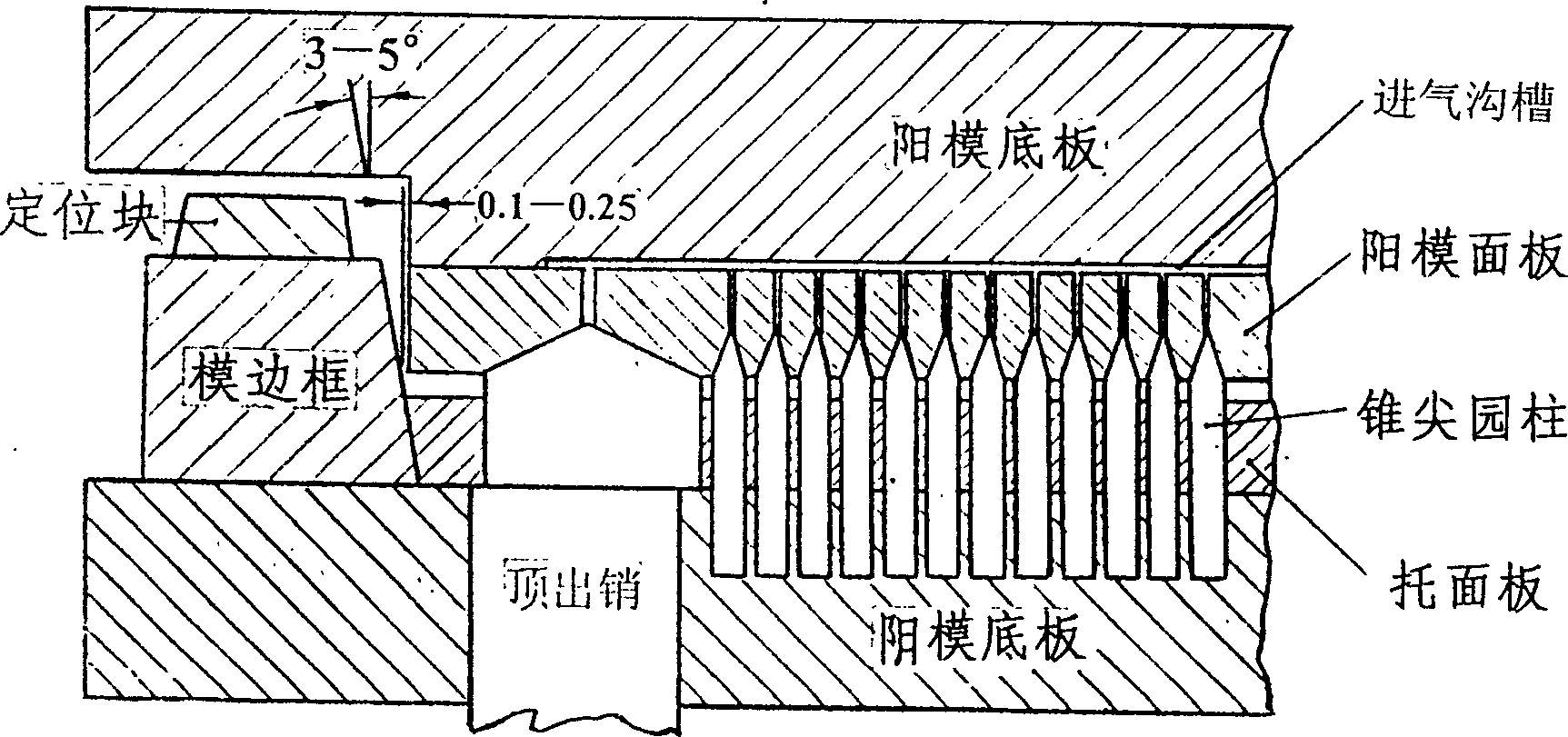

[0020] The production and implementation of the patented technology product of the present invention mainly includes molding and making of porous water-permeable panels, punching and shearing of water flow channel partitions and bonding of partitions, molding of side panels of glass fiber reinforced plastics, cutting and preparation of synthetic fiber fabrics and membranes, The process procedures such as membrane module assembly and fixation are described as follows for the specific implementation of the above process procedures:

[0021] 1. Molding and production of porous permeable panels

[0022] (1) Sheet molding compound SMC: The porous permeable panel is molded by glass fiber reinforced vinyl ester resin sheet molding compound (SMC). Vinyl ester resin is a new type of resin, which is developed on the basis of unsaturated polyester and epoxy resin, combining the advantages of both. In terms of performance, it retains the excellent properties of epoxy resin such as high m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com