Lens barrel made from glass fiber reinforced flame retardant resin composition

A technology of resin composition and thermoplastic resin, applied in the field of lens barrel, can solve the problems of low anisotropy and non-disclosure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

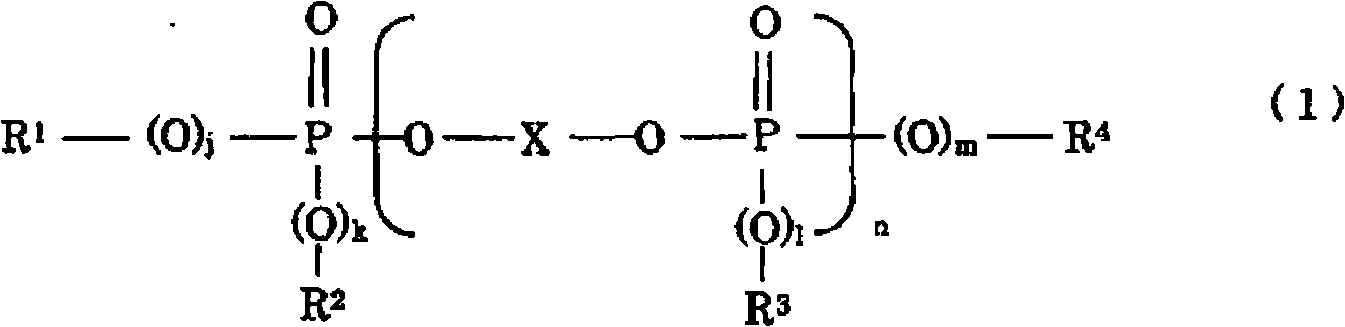

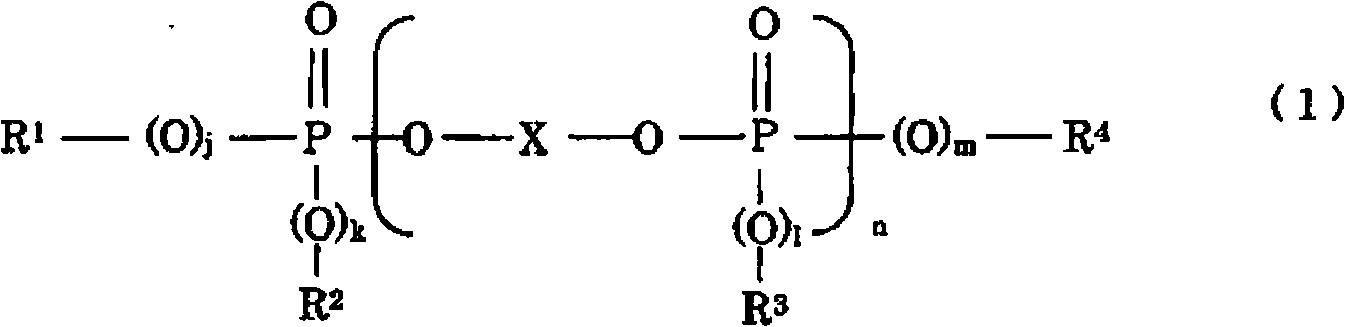

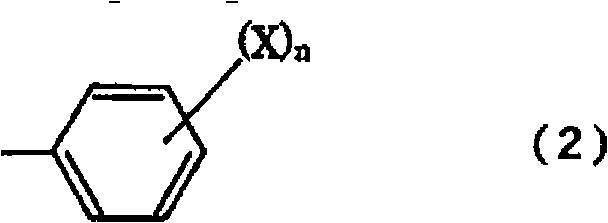

Method used

Image

Examples

specific Embodiment approach

[0219] The inventors of the present invention think that the best aspects of the present invention include the preferred ranges of the above-mentioned requirements, for example, representative examples thereof are described in the following examples. Of course, the present invention is not limited to these schemes.

Embodiment 1~4、 comparative example 1~3

[0231] The polycarbonate resin and the various additives described in Table 1 were mixed in each compounding amount with a blender, and then melt-kneaded using a vented twin-screw extruder to obtain pellets. The various additives used are pre-mixed with polycarbonate resin based on the concentration of 10-100 times the compounding amount, and then mixed with a blender. The vent type twin-screw extruder is made by Nippon Steel Works: TEX-30XSST (full meshing, same direction rotation, 2 screws). The extrusion conditions are discharge rate 20kg / h, screw rotation speed 150rpm, and vacuum degree of vent 3kPa. In addition, the extrusion temperature is set to 270°C from the first supply port to the second supply port, and 270°C from the second supply port to the second supply port. The die part is 280°C. In addition, the reinforcing filler was supplied from the second supply port using the side feeder of the extruder, and the remaining polycarbonate resin and additives were supplied...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com