Composite board and application thereof as composite material for fireworks and crackers transport vehicle carriage

A composite sheet and composite material layer technology, applied in the direction of transportation and packaging, the upper structure of trucks, vehicle parts, etc., can solve the problems that cannot fully guarantee the safety of the transportation process, reduce maintenance and inspection costs, reduce usage, The effect of high modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

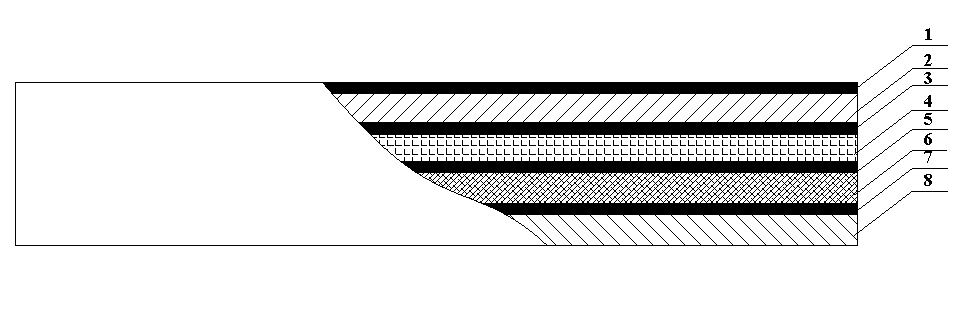

[0026] like figure 1 The composite plate shown in the figure is from top to bottom (from outside to inside when used as a box body material) in order of magnetic wave-absorbing material layer 1, bulletproof steel plate 2, unsaturated polyester resin doped with reinforcing fibers 3, polymer microporous material Layer 4, polyurethane adhesive 5, glass fiber reinforced resin composite material layer 6, polyamide viscoelastic resin 7 and conductive elastic alloy layer 8.

[0027] The magnetic wave-absorbing material layer 1 is formed by spraying a magnetic wave-absorbing material (such as a wave-absorbing coating composed of ferrite and other magnetic fillers dispersed in a dielectric polymer) on the bulletproof steel plate 2, and the coating thickness is About 0.3-0.5 mm; the bullet-proof steel plate is a 22Si2Mn2 type hot-rolled steel plate smelted in an electric arc furnace, with a thickness of about 5-10 mm. The polymer microporous material layer 4 adopts the ROHACELL series...

Embodiment 2

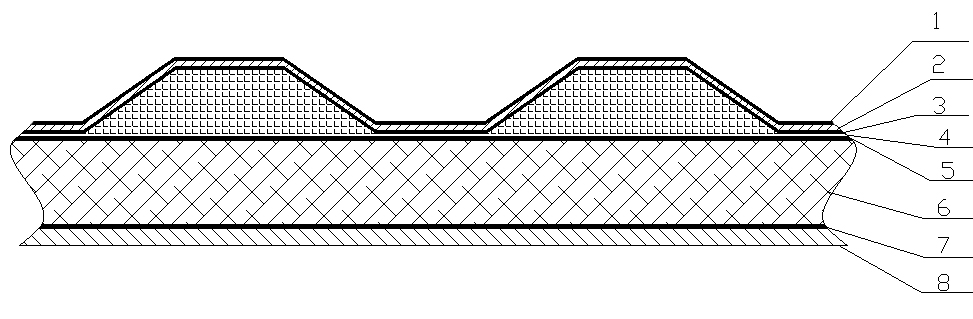

[0041] like figure 2, The bulletproof steel plate 2 can adopt a corrugated structure, which has the characteristics of light weight, high strength and low cost under the same load. The outer surface is uniformly coated with magnetic wave-absorbing material 1, and the polymer microporous material layer 4 can be fully filled in the gap between the corrugated bulletproof steel plate 2 and the glass fiber reinforced resin composite material layer 6 through effective technological means or methods, It can prevent moisture, buffer bullet penetration, and attenuate the impact of explosions. In addition, it also has high light reflection performance to prevent the bubbling of the car compartment caused by the high temperature of the sun. The inner layer is a conductive elastic alloy layer 8, which can make the aluminum alloy plate shield the external electromagnetic radiation and at the same time guide and eliminate the internal static electricity.

[0042] The bulletproof steel pla...

Embodiment 3

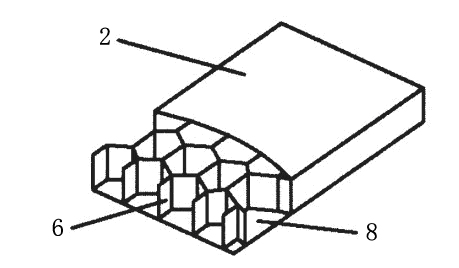

[0045] image 3 It is only a schematic diagram of the structure, and some structures (such as the microporous material layer) are not drawn, which is only convenient for the following description.

[0046] The glass fiber reinforced resin composite material layer 6 is used as a honeycomb sandwich core, and the surfaces are bulletproof steel plates 2 and high elastic conductive alloy 8 respectively, and the glass fiber reinforced resin composite material layer 6 is made into a honeycomb shape, and the above example is used between the conductive alloy layer In the resin bonding, the upper layer of the honeycomb sandwich material (or glass fiber reinforced resin composite material layer) is a microporous material bonded with resin. In a word, the difference from the above example is that only the glass fiber reinforced resin composite material layer 6 is no longer It is a simple flat structure, but a honeycomb structure, and the other layers remain unchanged. This kind of steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com