Manufacture device of glass fibre reinforced resin composite plate spring

A composite material board and reinforced resin technology, which is applied in the field of manufacturing devices for fiber-reinforced resin composite leaf springs, can solve the problem of not having a closed-circuit tension control function and the like, and achieve the effects of simple structure, high control precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further understood by the following examples.

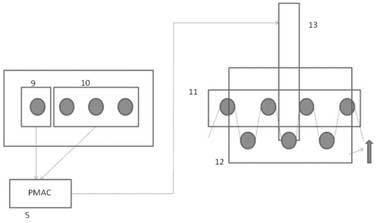

[0044] Such as figure 1 The preparation device shown includes servo motors 3, 7, 8 and servo motor drivers, tension sensor 4, PMAC controller 6, and a yarn guide system that can conduct multiple glass fibers side by side, mandrel, dipping tank, creel, etc. composition.

[0045] The servo motor 3 is provided with an encoder, the guide rail on the lead screw 13 drives a group of friction rollers on the steel plate to run up and down, the encoder is connected to the PMAC controller 4, and transmits the tension error signal obtained from the PMAC controller 4 to the servo motor 3 The motor driver, the motor driver is installed on the servo motor 3, and the work of the servo motor 3 is controlled by the motor driver

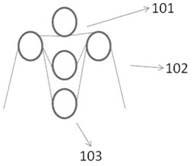

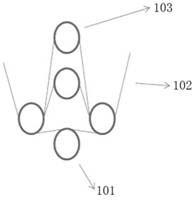

[0046] The friction rollers of the fixed roller frame 12 and the movable roller frame 11 are all cylindrical metal rollers, wherein 3 metal rollers are connected on the upper movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com