Hybrid basalt fiber and glass fiber reinforced resin

A basalt fiber and glass fiber technology is applied in the field of hybrid basalt fiber and glass fiber reinforced resin bars, which can solve the problems of low shear strength, poor alkali resistance of fibers, application limitations, etc. The effect of tensile strength, excellent alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

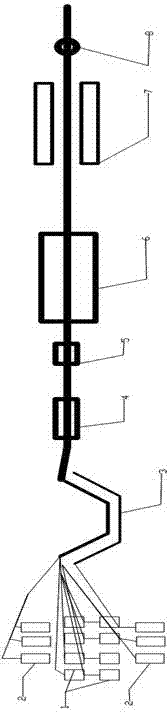

[0027] The invention also discloses a preparation method of mixed basalt fiber and glass fiber reinforced resin bar, which comprises the following steps:

[0028] 1), glass fiber and basalt fiber are respectively impregnated with resin;

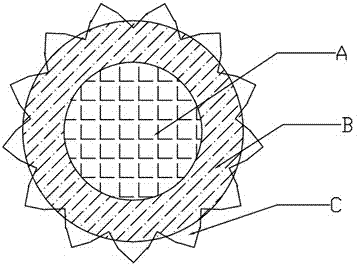

[0029] 2) Preliminarily molding the glass fiber and the basalt fiber respectively by using a mold forming device, wherein the basalt fiber is coated on the outside of the glass fiber to obtain an initial reinforced resin bar;

[0030] 3) Using a heating and curing device to heat and cure the initial reinforced resin bars obtained in step 2), to obtain hybrid basalt fiber and glass fiber reinforced resin bars.

[0031] Wherein, preferably, in step 3), a layer of quartz sand is first sprayed on the outside of the initial reinforced resin bar by using a sandblasting device, and then the initial reinforced resin bar obtained in step 2) is heated and cured by a heating and curing device to obtain a hybrid Basalt fiber and glass fiber reinforced r...

Embodiment 1

[0033] Prepare the mixed basalt fiber glass fiber reinforced resin bars with a diameter of 25MM according to the following raw materials and percentages:

[0034] raw material

glass fiber

45%

Basalt fiber

25%

[0035] Bisphenol A epoxy resin compound

30%

[0036] Bisphenol A epoxy resin mixture formula is as follows:

[0037] raw material

number of copies

Bisphenol A epoxy resin

100

Curing agent (methyltetrahydrophthalic anhydride)

85

8

Accelerator

1

[0038] Surface quartz sand specifications: 50--60 mesh. The dosage is based on the principle of evenly covering the product surface.

[0039] Preparation process

[0040] Such as figure 2 As shown, the glass fiber 1 and the basalt fiber 2 pass through the resin impregnation device 3 to impregnate the resin mixture, enter the mold forming device 4 for prelim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com