Electrical and electronic equipment part formed by injection moulding of glass fibre reinforced resin composition

A technology of electronic equipment and glass fiber, applied in the field of electrical and electronic equipment components, can solve problems such as non-satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

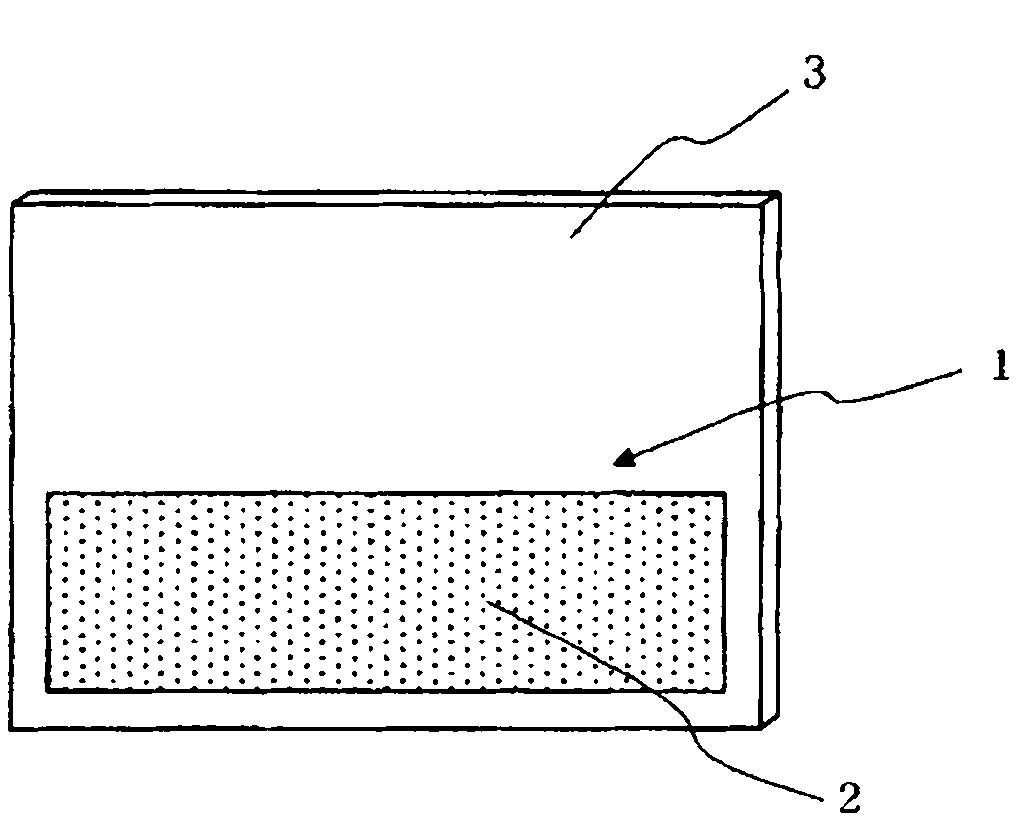

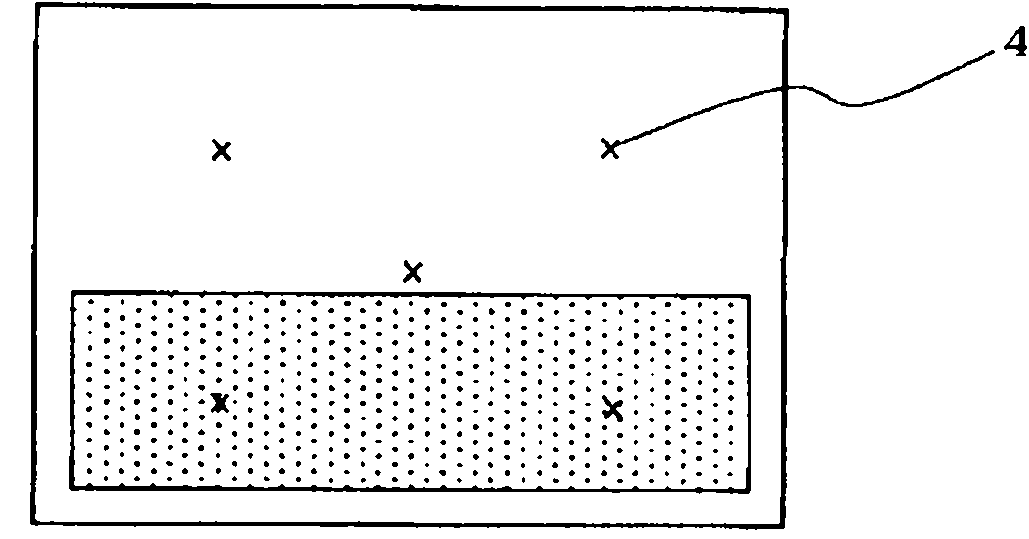

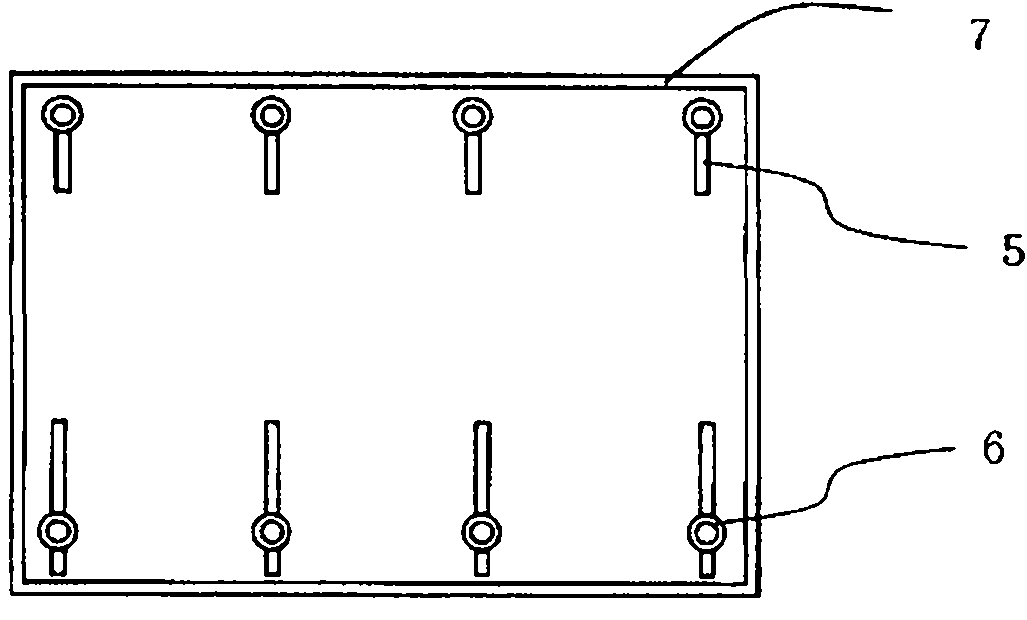

Image

Examples

Embodiment 1~12、 comparative example 1~7

[0189] With the compounding amounts listed in Tables 1 and 2, polycarbonate resin, styrene-based resin, reinforcing filler, phosphate-based flame retardant, and various additives were mixed with a blender, and then vented biaxial The extruder performs melt kneading to obtain pellets. Each of the various additives used is pre-mixed with the polycarbonate resin based on the concentration of 10 to 100 times the compounding amount, and then the whole is mixed with a blender. The vent type twin-screw extruder is made by Nippon Steel Works: TEX-30XSST (full meshing, same direction rotation, 2 screws). Extrusion conditions are discharge rate 20kg / h, screw rotation speed 150rpm, and vent vacuum 3kPa. In addition, the extrusion temperature is 280°C from the first supply port to the second supply port, and 280°C from the second supply port to the second supply port. The die part is 290°C. In addition, the reinforcing filler was supplied from the second supply port using the side feede...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com