Basalt continuous fibre enhancement resin composite material and manufacturing method thereof

A continuous fiber and composite material technology, applied in the field of basalt continuous fiber reinforced resin composite material and its manufacturing, can solve the problems of limited application, high price, poor hydrolytic corrosion resistance of glass fiber, etc., and achieves excellent chemical properties and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

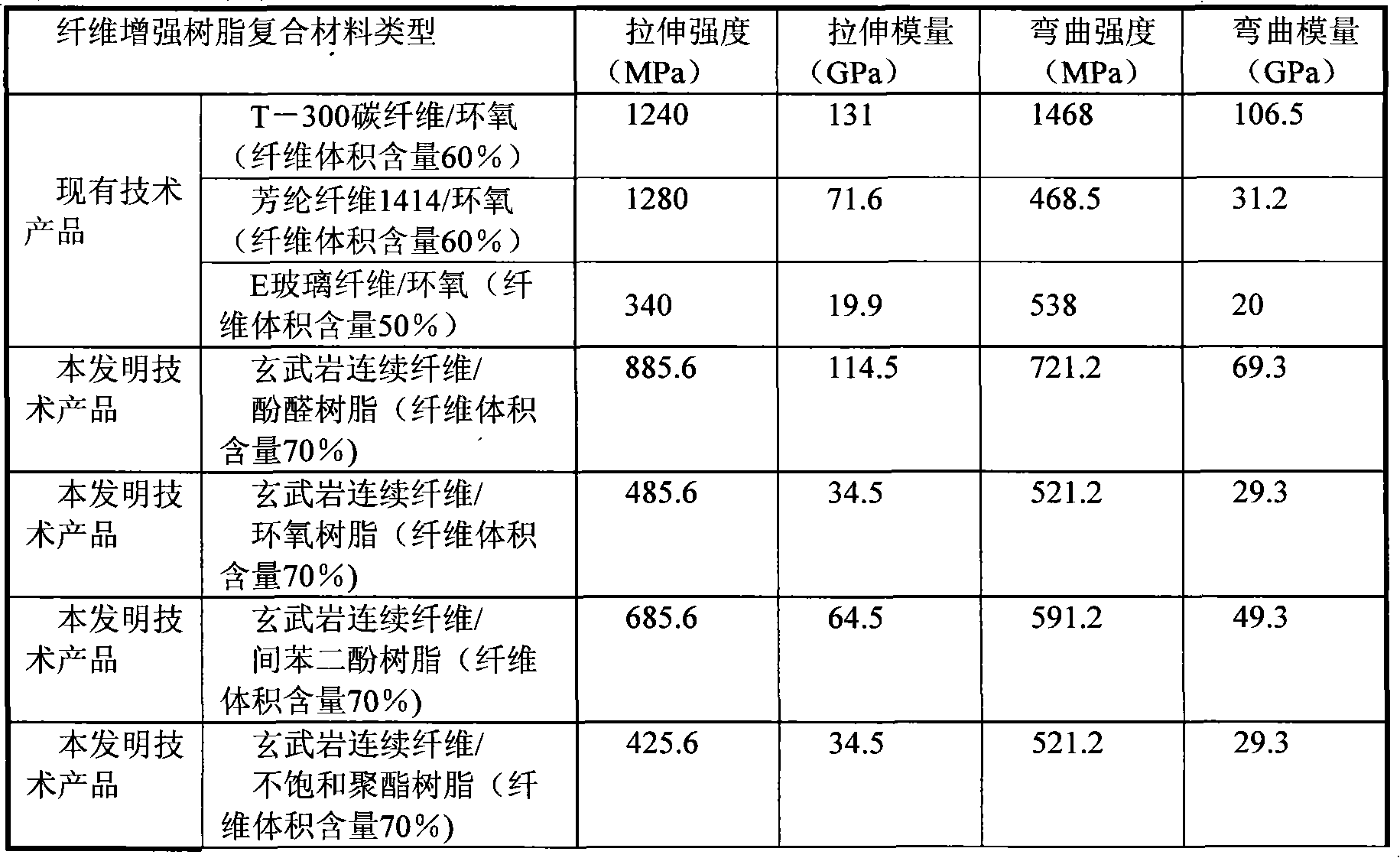

[0013] The preferred embodiment of the basalt continuous fiber reinforced resin composite material of the present invention includes raw materials: basalt continuous fiber and resin.

[0014] Wherein, the volume content of the basalt continuous fiber in the composite material is 10%-85%, and may be 10, 20, 30, 40, 50, 60, 70, 80, 85% and the like.

[0015] It also includes raw materials: silane coupling agent, which is used to promote the surface activation of basalt continuous fiber and combine with resin.

[0016] The resin includes at least one of the following resins:

[0017] Unsaturated polyester resin, phenolic resin, epoxy resin, resorcinol resin, vinyl resin, amino resin, or various modified unsaturated polyester resins, phenolic resin, epoxy resin, resorcinol resin , vinyl resin, amino resin, etc., or other resins.

[0018] The manufacturing method of the basalt continuous fiber reinforced resin composite material of the present invention mainly comprises:

[0019...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com