Preparation method of carbon nanotube-montmorillonoid self-assembled nano powder grafting glass fiber reinforced resin composite material

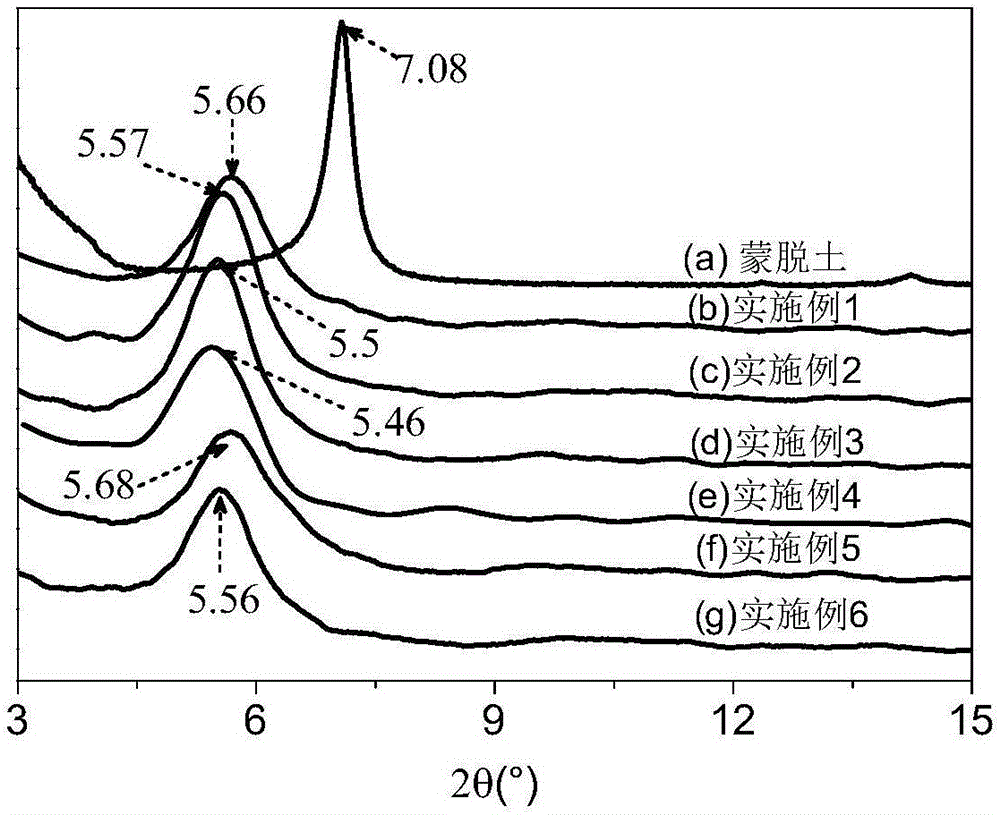

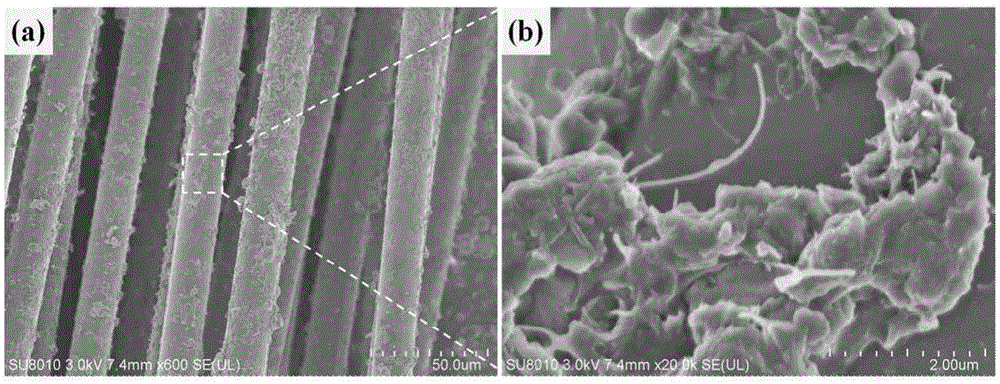

A technology of carbon nanotubes and glass fibers, which is applied in the field of fiber-reinforced polymer composite materials, can solve the problems of uneven dispersion of nanofillers, uneven distribution of CNTs at the injection port and the exit port, etc., so as to increase the layer spacing and avoid easy winding , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a carbon nanotube-montmorillonite self-assembled nano powder grafted glass fiber reinforced composite material, the specific steps are as follows:

[0033] (1) Aminated carbon nanotubes: Weigh 0.2g of carboxyl multi-walled carbon nanotubes and add them to 0.02L of N,N'-dimethylformamide solvent, then add 0.005g of N,N'-diisopropyl Carbodiimide and 1-hydroxybenzotriazole were stirred for 5 minutes and ultrasonicated for 30 minutes to obtain a 10 g / L carbon nanotube dispersion, which was magnetically stirred at a speed of 200 r / min; weighed 0.01 g of diethylene Triamine was added to the carbon nanotube dispersion, and after reacting at room temperature for 24 hours, it was washed twice with deionized water and washed with alcohol, and then filtered to obtain diethylenetriamine-modified carbon nanotubes;

[0034] (2) Preparation of carbon nanotube ammonium salt: the carbon nanotube modified by diethylenetriamine in step (1) was stirred in 0.02L deion...

Embodiment 2

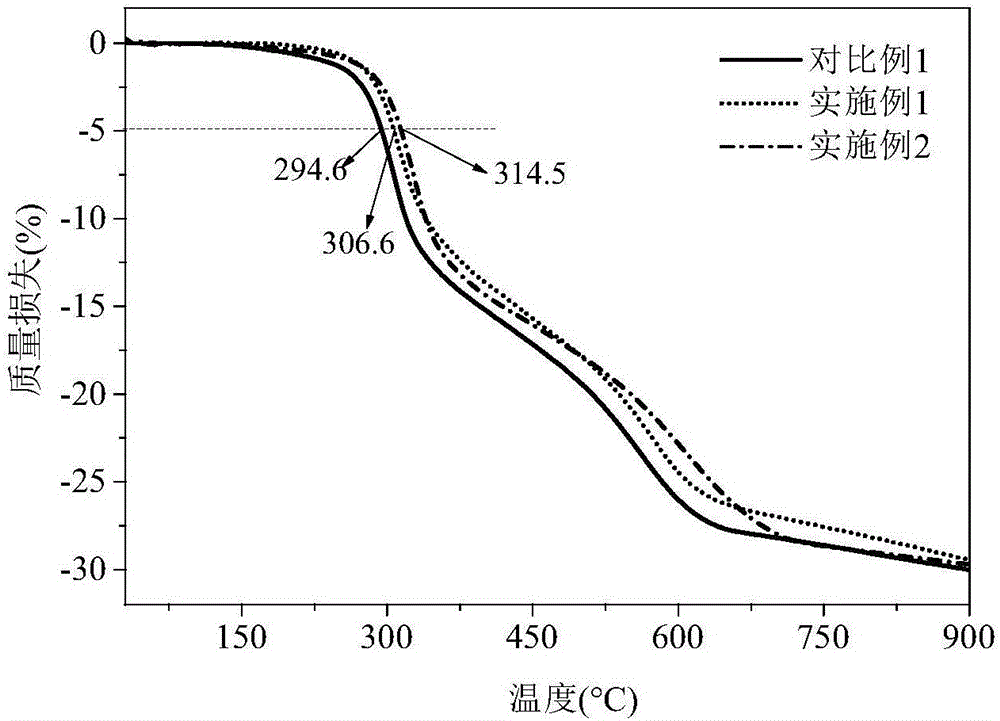

[0040] A kind of carbon nanotube-montmorillonite self-assembled nanopowder and preparation method thereof, its place differs from embodiment 1 in that the carboxyl carbon nanotube described in step (1) becomes 1g, and described N, N' -Diisopropylcarbodiimide and 1-hydroxybenzotriazole become 0.02g respectively, and described organic amine becomes 0.2g triethylenetetramine; The solution pH value described in step (2) is adjusted to 4; in step (3), 10g montmorillonite is added to 100mL deionized water, stirred at 1000r / min for 3h, ultrasonic 1h; carbon nanotube ammonium salt is stirred at 800r / min in the montmorillonite suspension, and Continue to stir for 5h; the silane coupling agent described in step (4) becomes 0.03g of 3-(2,3-epoxypropoxy)propyltriethoxysilane, and adjust the pH of the silane coupling agent solution with acetic acid to 4.0; the quality of the nano-powder is changed to 3g; the composite material molding process in step (5) is changed to a vacuum-assisted res...

Embodiment 3

[0043]A carbon nanotube-montmorillonite self-assembled nanopowder and a preparation method thereof, which differ from Example 1 in that the carboxyl carbon nanotubes described in step (1) become 1g, and the aprotic organic solvent Become carbon tetrachloride, described dehydration condensation agent becomes ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC) and N-hydroxyl succinimide (NHS), Described organic amine becomes 0.05g tetraethylene pentamine; Solution pH value is adjusted to 3.5 with hydrochloric acid in step (2), and described rotating speed is adjusted to 600r / min; Montmorillonite quality described in step (3) changes 5g, the cation exchange capacity of montmorillonite becomes 100mmol / 100g, and the stirring speed of the carbon nanotube ammonium salt in the montmorillonite suspension is 600r / min. The silane coupling agent described in the step (4) becomes N-(2-aminoethyl)-3-aminopropyltriethoxysilane; the described glass fiber material is that the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Decomposition temperature | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com