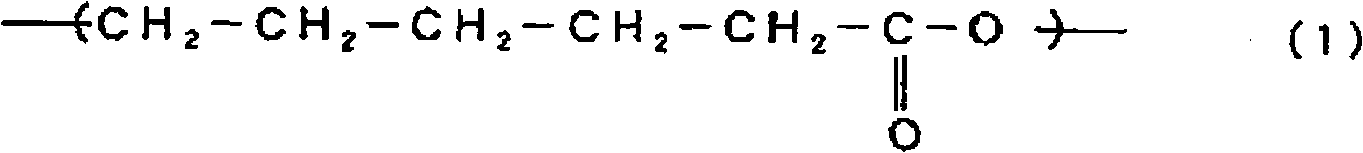

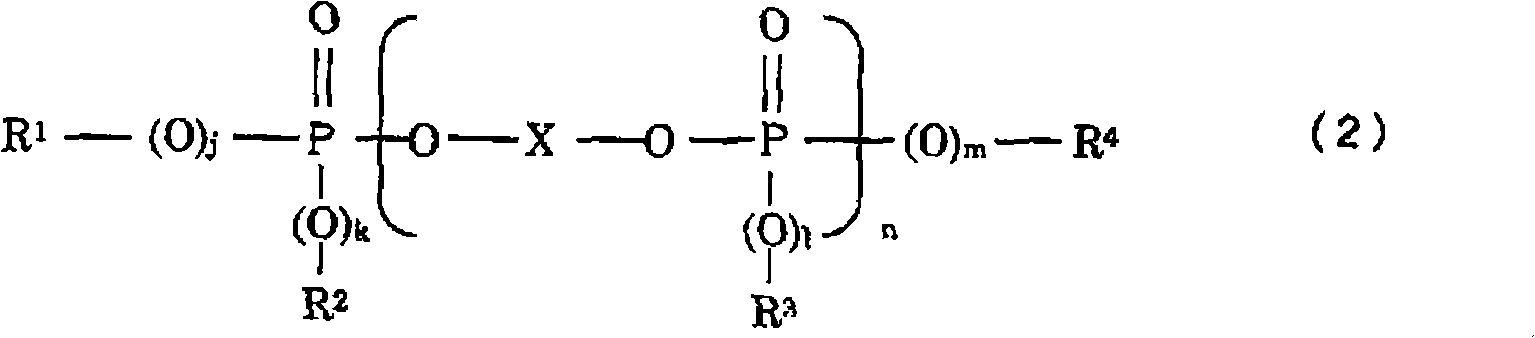

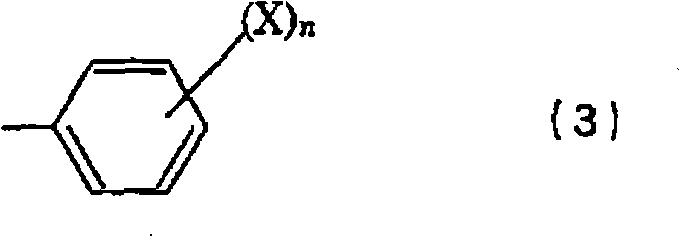

Glass fiber reinforced resin composition

A technology of reinforcing resin and glass fiber, which can be used in cameras, instruments, optics, etc., and can solve the problems of no mechanical strength, low anisotropy, flame retardancy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15、 comparative example 1~5

[0236] With the compounding amounts recorded in Tables 1 and 2, polycarbonate resin, reinforcing filler, polycaprolactone and various additives were mixed with a blender, and then melted and kneaded with a vented twin-screw extruder. Get pellets. Each of the various additives used is pre-mixed with the polycarbonate resin based on the concentration of 10 to 100 times the compounding amount, and then the whole is mixed with a blender. The vent type twin-screw extruder is made by Nippon Steel Works: TEX-30XSST (full meshing, same direction rotation, 2 screws). The extrusion conditions are discharge rate 20kg / h, screw rotation speed 150rpm, and vacuum degree of the vent port 3kPa. In addition, the extrusion temperature is 290°C from the first supply port to the second supply port, and 290°C from the second supply port to the second supply port. The die part is 300°C. In addition, the reinforcing filler was supplied from the second supply port using the side feeder of the extrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com