Composite sectional material and door/ window frame or glass curtain wall frame

A technology of composite profiles and profiles, applied in the installation of window glass, walls, and wing frames, etc., can solve the problems of cumbersome and complicated installation process, waste of time and labor costs, etc., to simplify the installation process, ensure sealing performance, and thermal conductivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

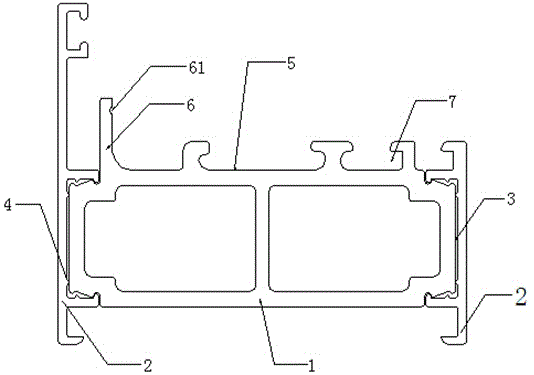

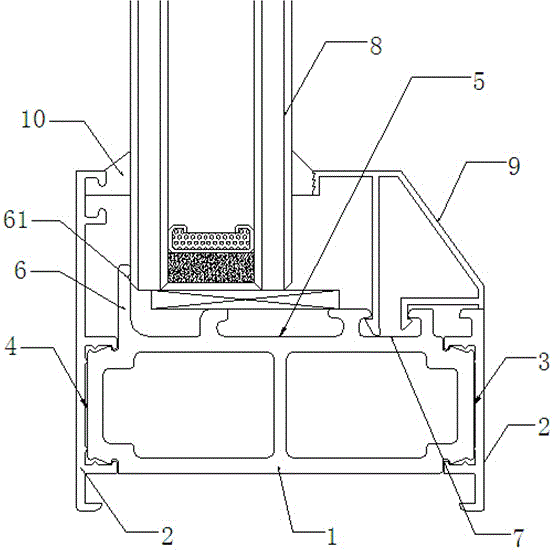

[0027] Such as figure 1 , figure 2 As shown, a composite profile has the same cross-section at different positions along its length direction, including a continuous glass fiber reinforced resin profile 1 and an aluminum layer 2 as a decorative panel, used to prepare door and window frames or glass curtain wall frames, continuous glass The fiber-reinforced resin profile 1 is provided with a working surface 5 for installing glass 8 on one or both sides, and an inner wall 3 and an outer wall 4 facing indoors and outdoors. The aluminum layer 2 is arranged on the outer wall 4 of the continuous glass fiber-reinforced resin profile 1. Face 5 is provided with mounting means for mounting glass 8 .

[0028] The installation mechanism includes a rib 6 protruding from the working surface 5, and the height of the rib 6 on the working surface 5 is greater than the gap between the glass 8 and the working surface 5 when the glass 8 is installed; The fiber-reinforced resin profile 1 and th...

Embodiment 2

[0031] The rest are the same as the above-mentioned embodiments, except that the resin in the continuous glass fiber reinforced resin profile is selected from one of polyurethane resin, unsaturated resin, phenolic resin, epoxy resin, polypropylene resin and nylon; the continuous glass fiber The continuous glass fiber in the reinforced resin profile accounts for 30-83% of the total weight of the continuous glass fiber-reinforced resin profile; the resin in the continuous glass fiber-reinforced resin profile accounts for 17-45% of the total weight of the continuous glass fiber-reinforced resin profile; its raw material composition Sections are generally of the following types:

[0032] Type 1, the continuous glass fiber in the product accounts for 83% of the profile weight, and the polyurethane resin accounts for 17%;

[0033] Type 2, the continuous glass fiber in the product accounts for 30% of the profile weight, the glass fiber fabric accounts for 15% of the profile weight, t...

Embodiment 3

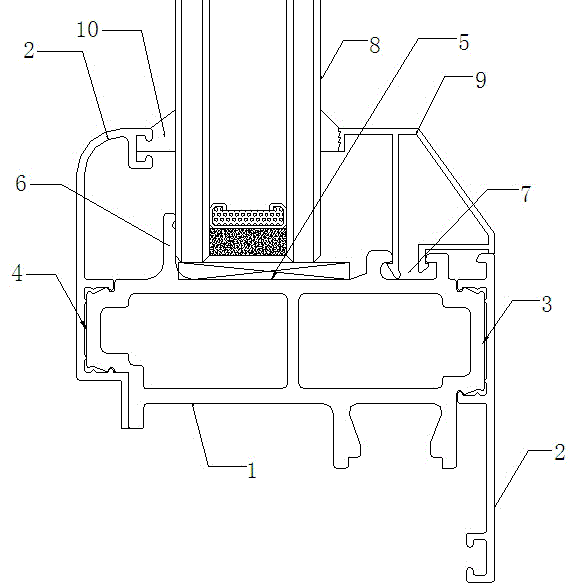

[0037] The rest are the same as in Example 1, except that the aluminum layer 2 is an aluminum profile, which increases the implementation of composite profiles, which can meet various needs; the aluminum profiles are arranged on the inner wall 3 and the outer wall 4 of the continuous glass fiber reinforced resin profile, It can be made into frame materials and fan materials of different shapes. The schematic diagram of frame material installation is as follows figure 2 As shown, the fan material installation diagram is as follows Figure 3-Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com