Cylinder produced from glass fiber-reinforced resin composition

A technology of resin composition and lens barrel, which is applied in the field of lens barrel and can solve the problems of not being disclosed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

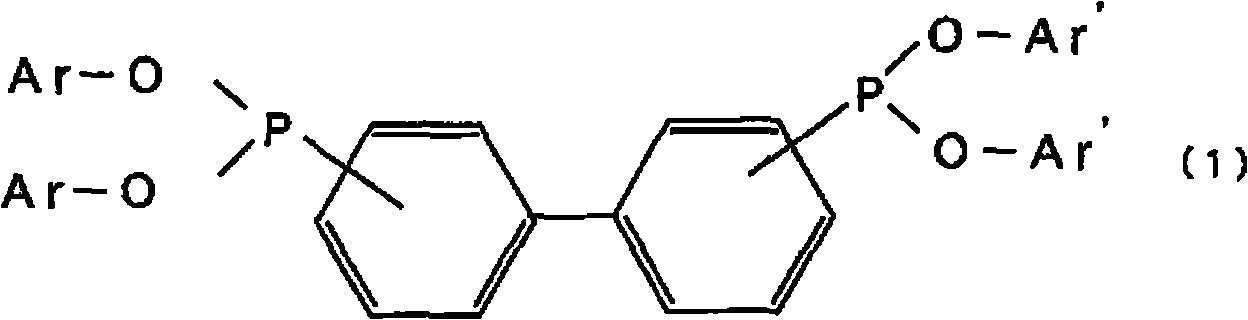

Method used

Image

Examples

Embodiment 1-14

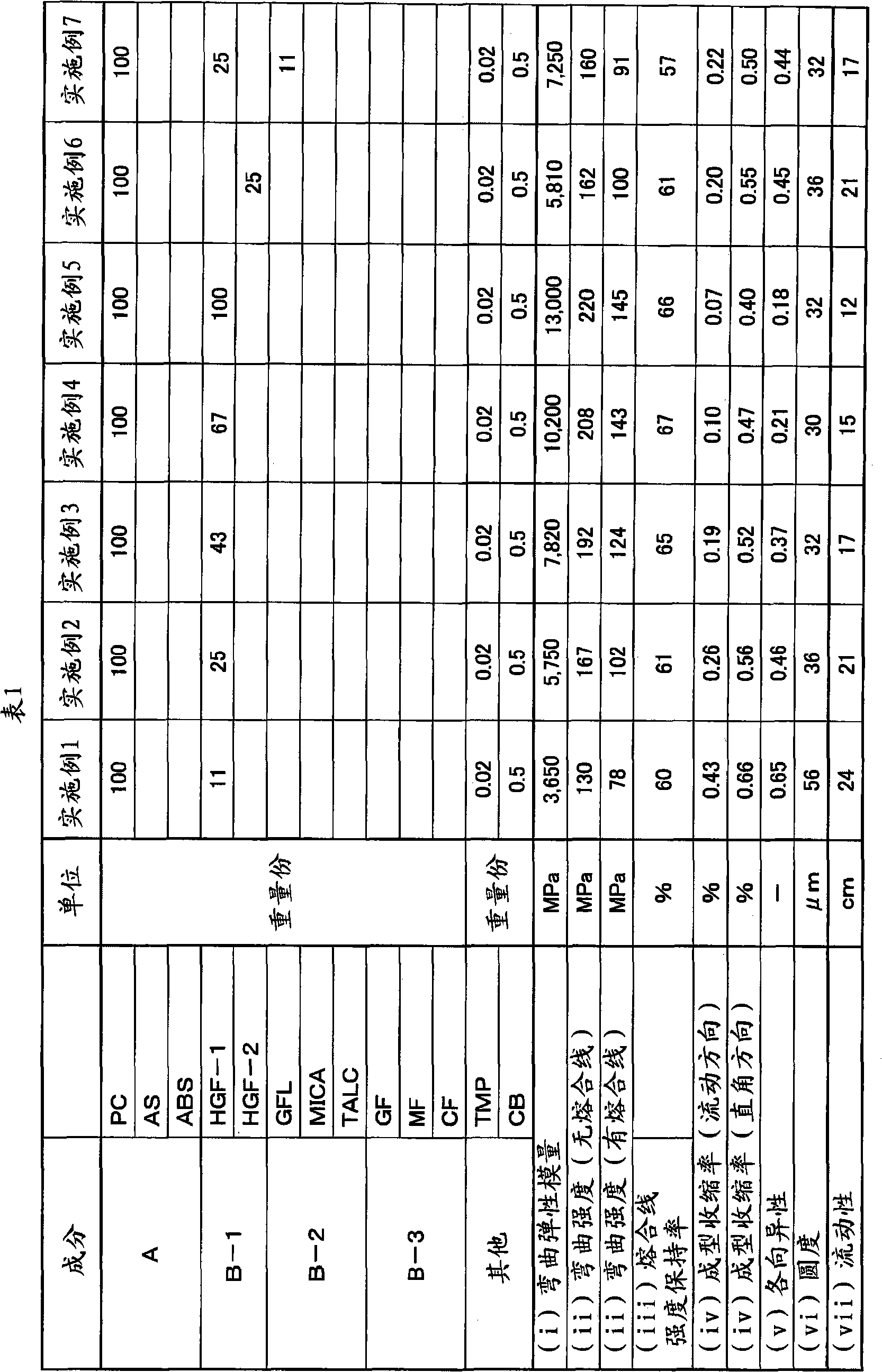

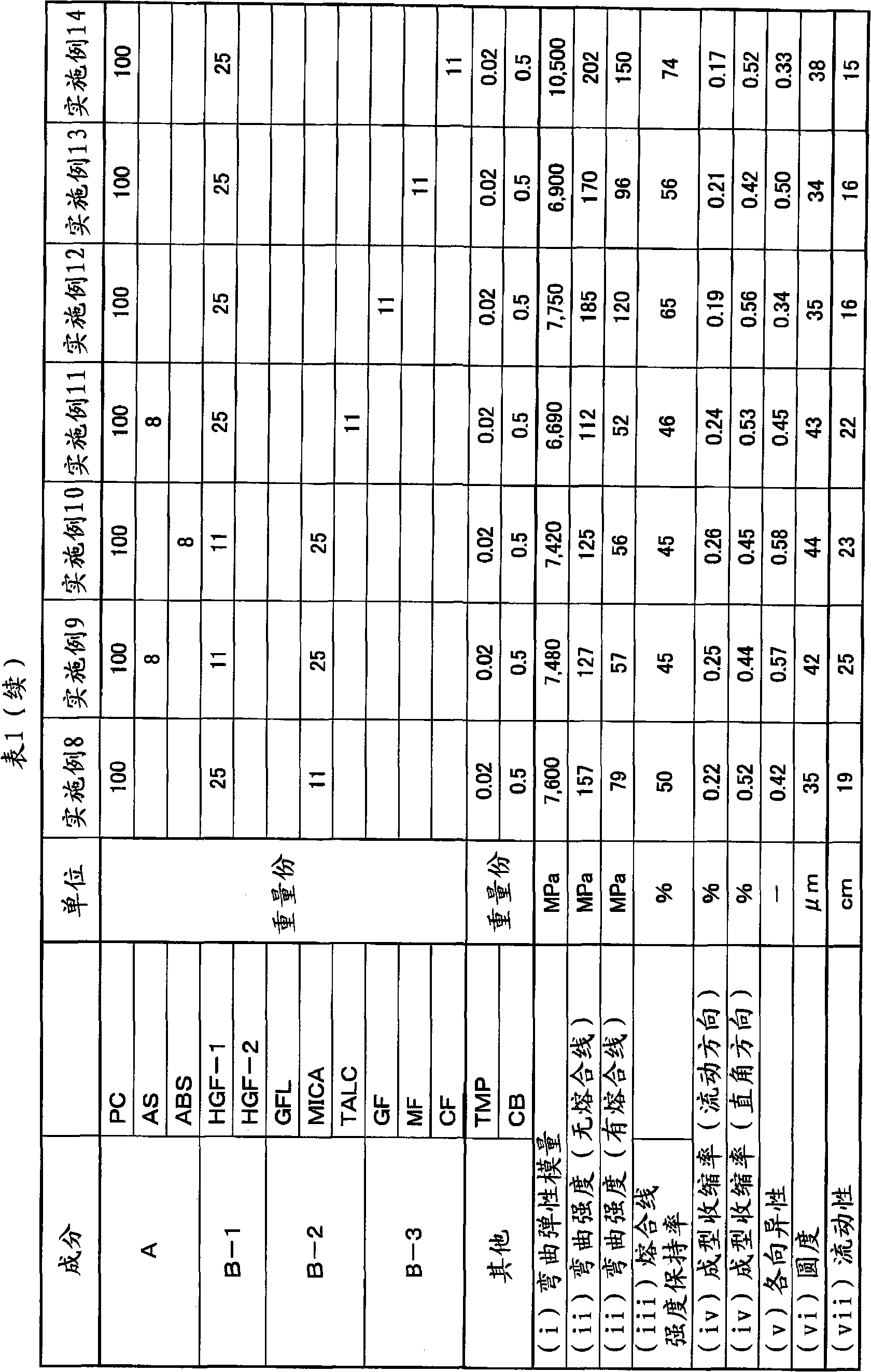

[0186] Embodiment 1-14, comparative example 1-11

[0187] With the compounding amounts listed in Table 1-Table 2, polycarbonate resin, styrene-based resin, flat cross-section glass fiber and various additives were mixed with a blender, and then melt-mixed with a vented twin-screw extruder. refining to obtain pellets. The flat cross-section glass fiber and various additives used are pre-mixed with polycarbonate resin based on the concentration of 10-100 times the compounding amount, and then the whole is mixed with a blender. The vent type twin-screw extruder is made by Nippon Steel Works: TEX-30XSST (full meshing, same direction rotation, 2 screws). The extrusion conditions are discharge rate 20kg / h, screw rotation speed 150rpm, and vacuum degree of vent 3kPa. In addition, the extrusion temperature is set to 270°C from the first supply port to the second supply port, and 270°C from the second supply port to the second supply port. The die part is 280°C. In addition, the rei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com