Temperature and humidity adjusting device for safety test chamber system

A temperature adjustment device, humidity adjustment technology, applied in control/adjustment systems, non-electric variable control, instruments, etc., can solve problems that have not been disclosed to the public, and achieve the effect of eliminating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

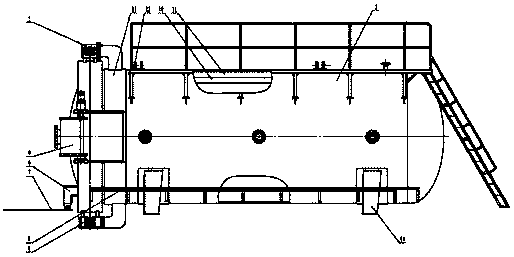

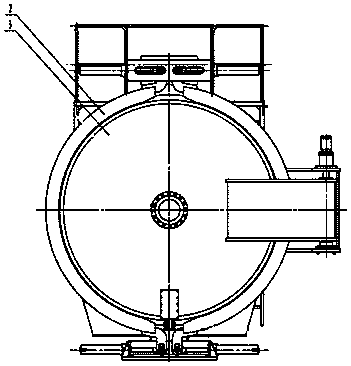

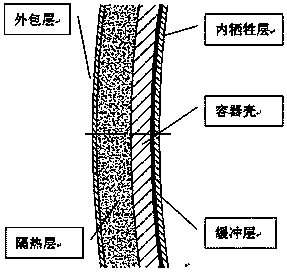

[0028] The invention provides a safety test cabin system, which is installed in a factory building, which includes a test cabin body, a fire extinguishing device, a temperature and humidity adjustment device, a gas replacement device, a test monitoring control device, a main control device, and a fire extinguishing and fire fighting device. The device, temperature and humidity adjustment device, and gas replacement device are arranged side by side on the side of the factory building. The test monitoring control device includes a test monitoring control panel and a test monitoring control cabinet. The main control device includes a main control panel and a main control cabinet. The test monitoring control panel, main The control panel, test monitoring control cabinet, and main control cabinet are arranged in the same independent room. The test air source control room is set on the right side of the fire extinguishing and fire fighting device. The user test air source control room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com