Ultra-deep water multifunctional flexible pipe and manufacturing method thereof

A manufacturing method and multi-purpose technology, applied in the direction of hoses, pipes, applications, etc., can solve the problems of poor gas permeability resistance, poor flexibility, poor pressure resistance, etc., and achieve low high temperature and high pressure resistance, high specific strength, and low installation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

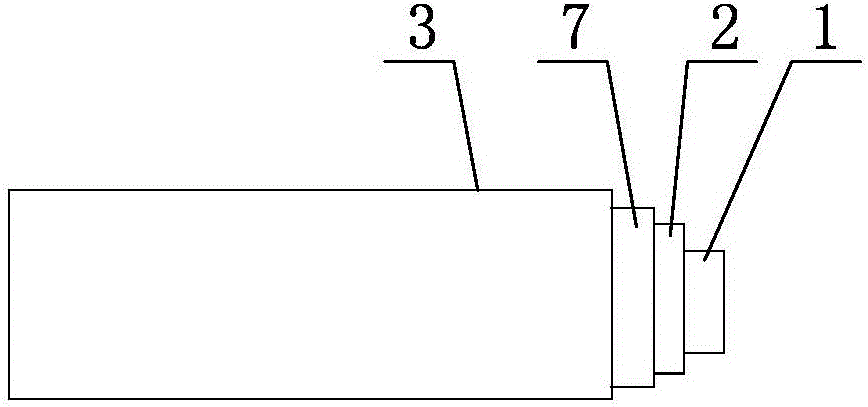

[0059] (1) Extrude ultra-high molecular weight polyethylene (UHMWPE) through an extruder to obtain the inner liner 1. The extrusion process conditions are as follows: extrusion thickness 30mm, extrusion temperature 150-180°C, vacuum degree 0.03MPa, traction speed 3m / min.

[0060] (2) Preheat the reinforcement tape with hot air, and then roll it into the winding drum of the winding machine, and heat it with laser to make it welded on the inner liner 1 while winding. When the first layer of reinforcement tape is wound, the reinforcement tapes of other layers are wound in the same manner one after another, and after the winding is completed, it is cooled and shaped by a cooling box containing cooling water to form the reinforcement layer 2 .

[0061] The width of the reinforcement tape is 30mm, the thickness is 0.2mm, the number of winding layers is 160, and the winding angle is ±30°, that is, the first layer is +30° or -30°, and the second layer is opposite to the first layer. ...

Embodiment 2

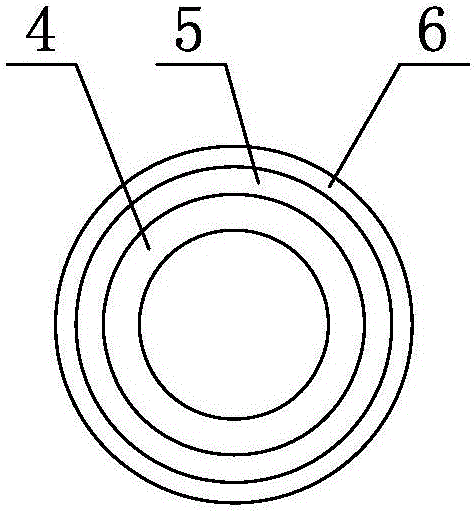

[0066] (1) The materials of the inner layer 4 , the middle layer 5 and the outer layer 6 are composited into one by three-layer co-extrusion to obtain the inner lining layer 1 . The inner layer 4 is a polyphenylene sulfide (PPS) or vinyl alcohol copolymer (EVCOH) layer, the middle layer 5 is an adhesive adhesive layer such as hot melt adhesive, and the outer layer 6 is a polyethylene (PE) layer.

[0067] (2) The reinforcing tape is preheated by the heating box, and then rolled into the winding drum of the winding machine, and laser heating is carried out while winding to make it welded to the inner liner 1 . When the first layer of reinforcement tape is wound, the reinforcement tapes of other layers are wound in the same manner one after another. After the winding is completed, the reinforcement layer 2 is formed by cooling and shaping in a cooling box containing cold air.

[0068] The width of the reinforcement tape is 50mm, the thickness is 0.35mm, the number of winding laye...

Embodiment 3

[0075] (1) The materials of the inner layer 4 , the middle layer 5 and the outer layer 6 are composited into one by three-layer co-extrusion to obtain the inner lining layer 1 . The inner layer 4 is a polyether ether ketone (PEEK) layer, the middle layer 5 is a hot melt adhesive layer, and the outer layer 6 is a polyamide (PA) layer.

[0076] (2) Preheat the reinforcement tape by laser, and then roll it into the winding drum of the winding machine, and heat it with laser to make it welded on the inner liner 1 while winding. When the first layer of reinforcement tape is wound, the reinforcement tapes of other layers are wound in the same manner one after another, and after the winding is completed, it is cooled and shaped by a cooling box containing cooling water to form the reinforcement layer 2 .

[0077] The width of the reinforcement tape is 70mm, the thickness is 0.25mm, the number of winding layers is 70, and the winding angle is ±70°, that is, the first layer is +70° or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com