A butterfly cable production line and a production process for preventing optical fiber retraction

A production process and production line technology, used in optics, light guides, optical components, etc., can solve problems such as fiber breakage, low yield, poor contact, etc., to improve product competitiveness, ensure production quality and yield, and improve endurance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

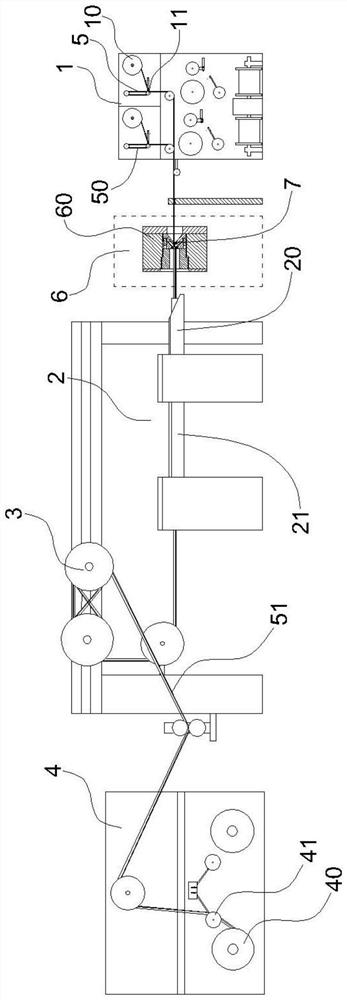

[0028] Such as figure 1 As shown, a butterfly cable production line corresponding to a preferred embodiment of the present invention includes a pay-off device 1 , an extruder 6 , a cooling device 2 , a wire storage rack 3 and a wire take-up device 4 .

[0029] The pay-off device 1 includes a plurality of pay-off wheels 10 and a plurality of first tensioning wheels 11. The pay-off wheels 10 are used to place coiled optical fibers 5 and reinforcing members 50. The pay-off wheels 10 are driven by a motor to rotate and pay off. The tensioning wheel 11 can control the pay-off tension of the optical fiber 5 and the reinforcing member 50; the take-up device 4 includes a take-up wheel 40 and a plurality of second tensioning wheels 41, and the take-up wheel 40 is driven by a motor to rotate and take up the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com