Oil pump with variable displacement

A displacement machine, oil pump technology, applied in the direction of lubrication pump, mechanical equipment, engine components, etc., can solve the problems of limited variation range of oil pump displacement, failure to achieve precise control, limited energy consumption, etc., to avoid the engine The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

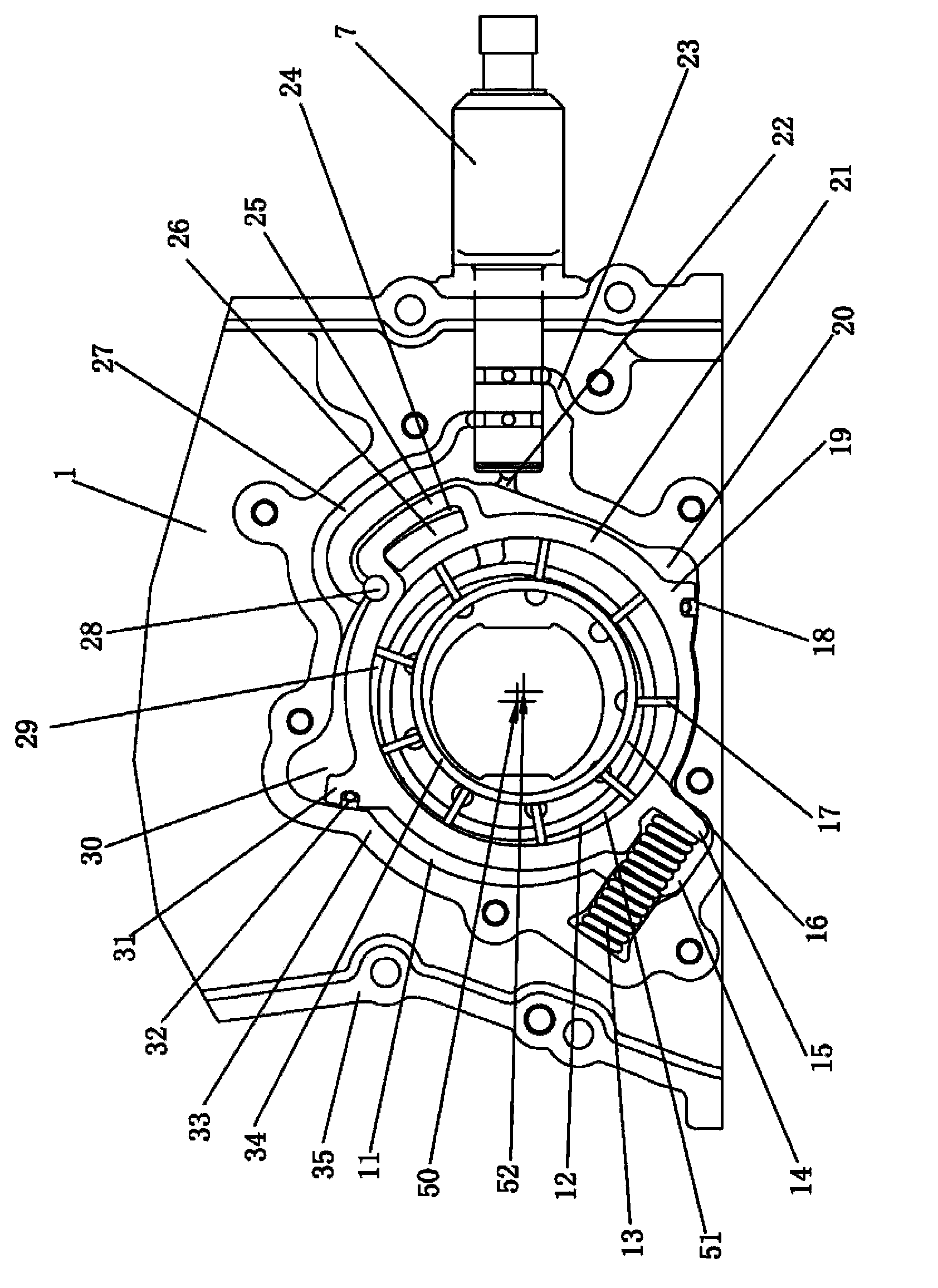

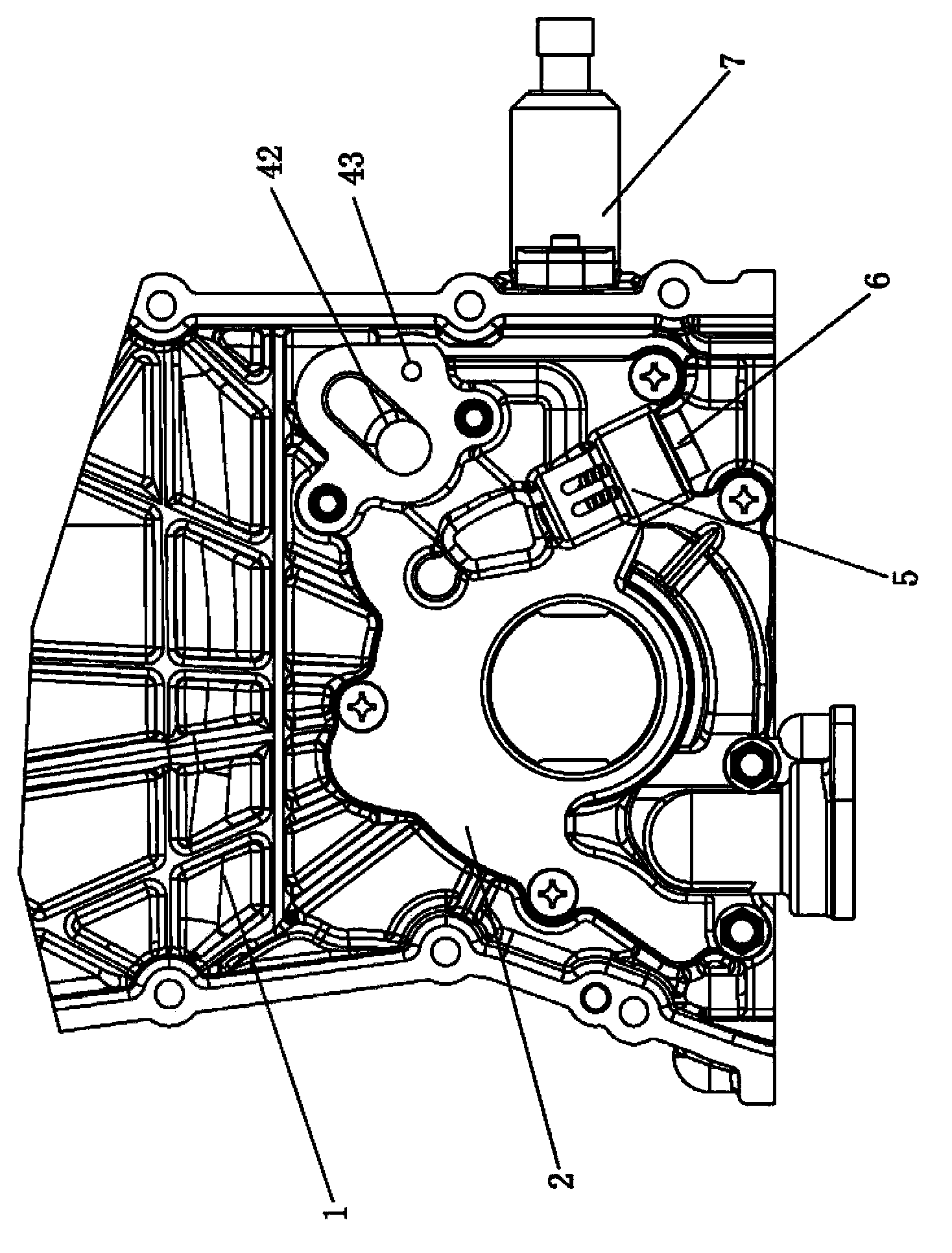

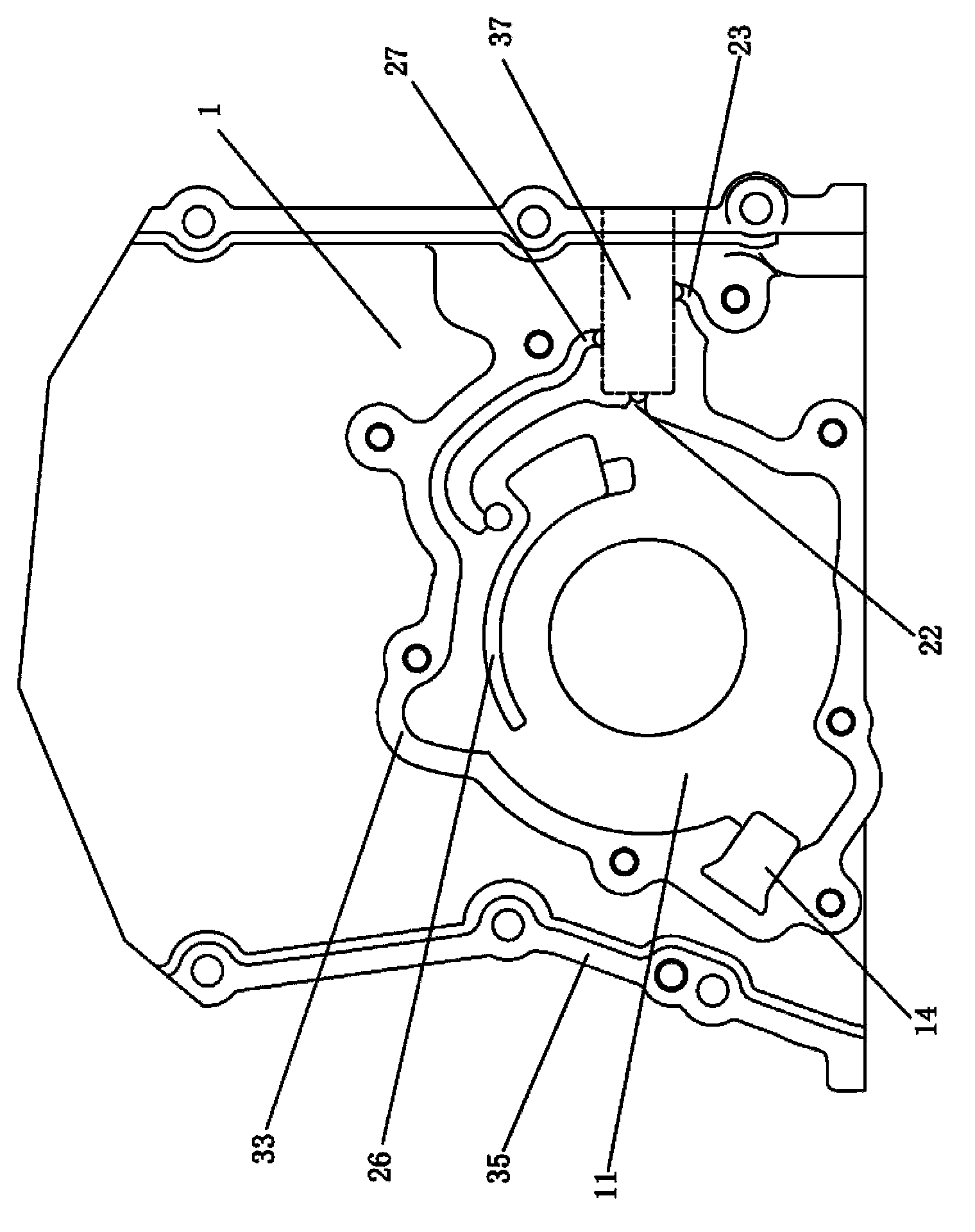

[0021] The invention discloses an electronically controlled two-stage variable-displacement engine oil pump integrated in the engine front cover. The invention not only realizes compact overall structure, miniaturization and light weight of the oil pump body, but also fully meets the different requirements of the engine oil flow under different speeds and loads by applying the electronically controlled two-stage variable displacement technology. Realize the adjustment of the displacement of the oil pump, avoid the useless work done by the oil pump, thereby reducing the power consumption of the whole machine by the oil pump, and achieve the effects of energy saving and emission reduction. The invention can accurately control the flow rate of the oil pump according to the working conditions of the engine, thereby effectively reducing the driving work of the oil pump, finally reducing the oil consumption rate of the engine, and achieving the purpose of energy saving and emission r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com