Thermostat for heat exchange loop

A thermostat and thermal circuit technology, applied in the field of machinery, can solve the problems of loss of lubricating performance and high temperature of transmission oil, and achieve the effect of reducing the number of components, increasing the conduction area, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0031] The orientation nouns such as top, bottom, left, and right described in the present invention are all described according to the relationship between up, down, left, and right in the accompanying drawings;

[0032] The above definitions are applicable in all statements herein, and will not be repeated hereafter.

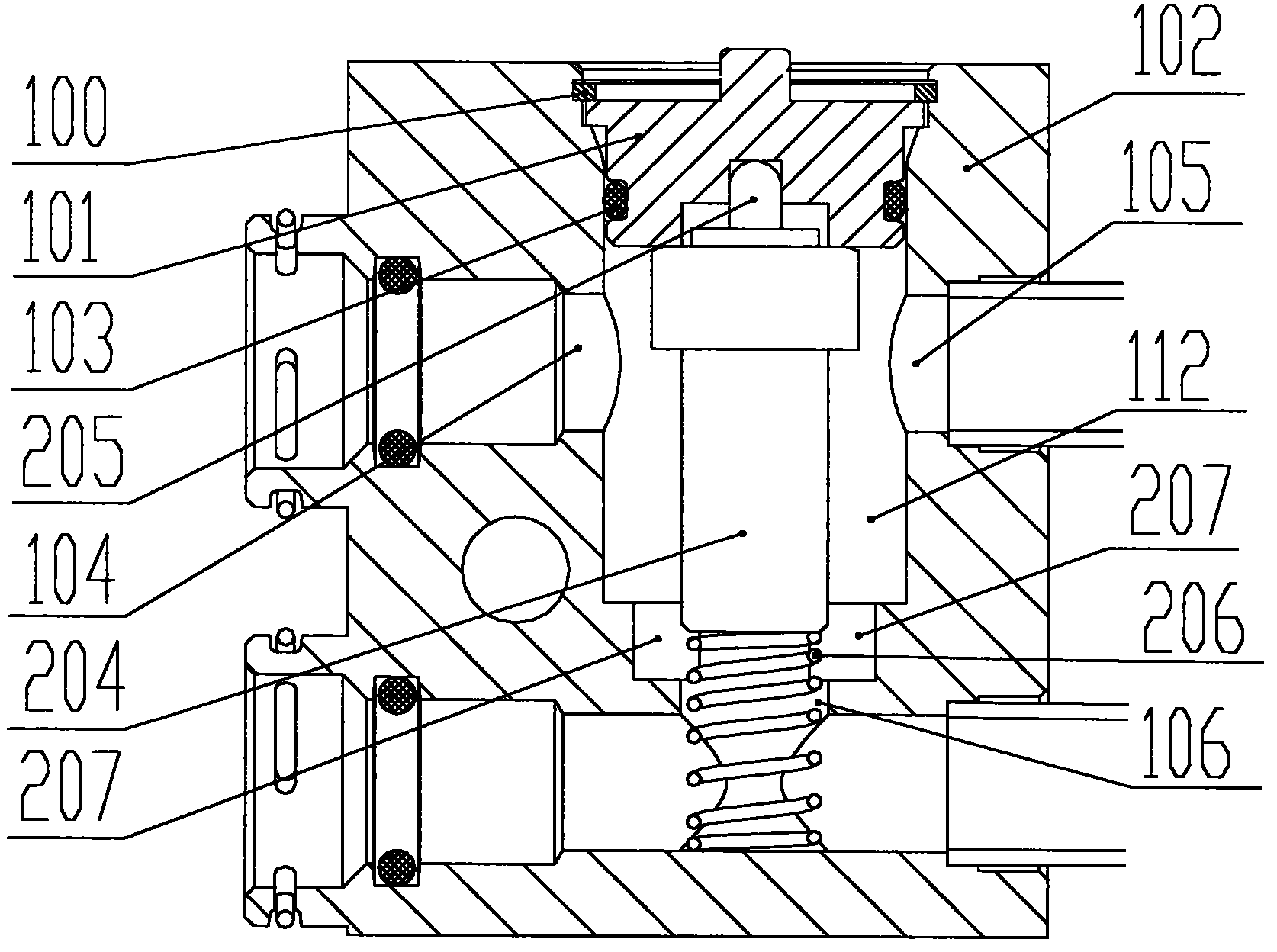

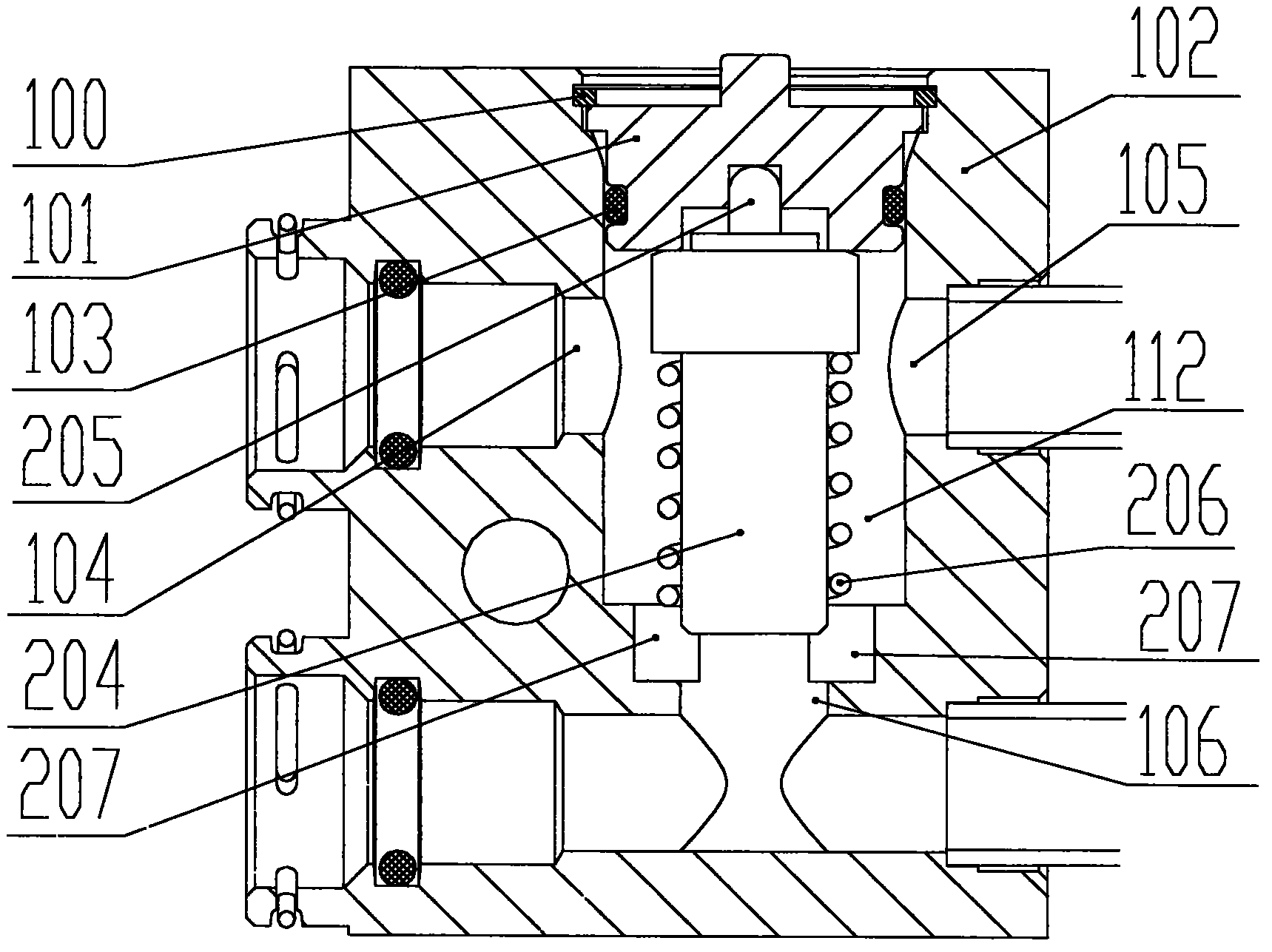

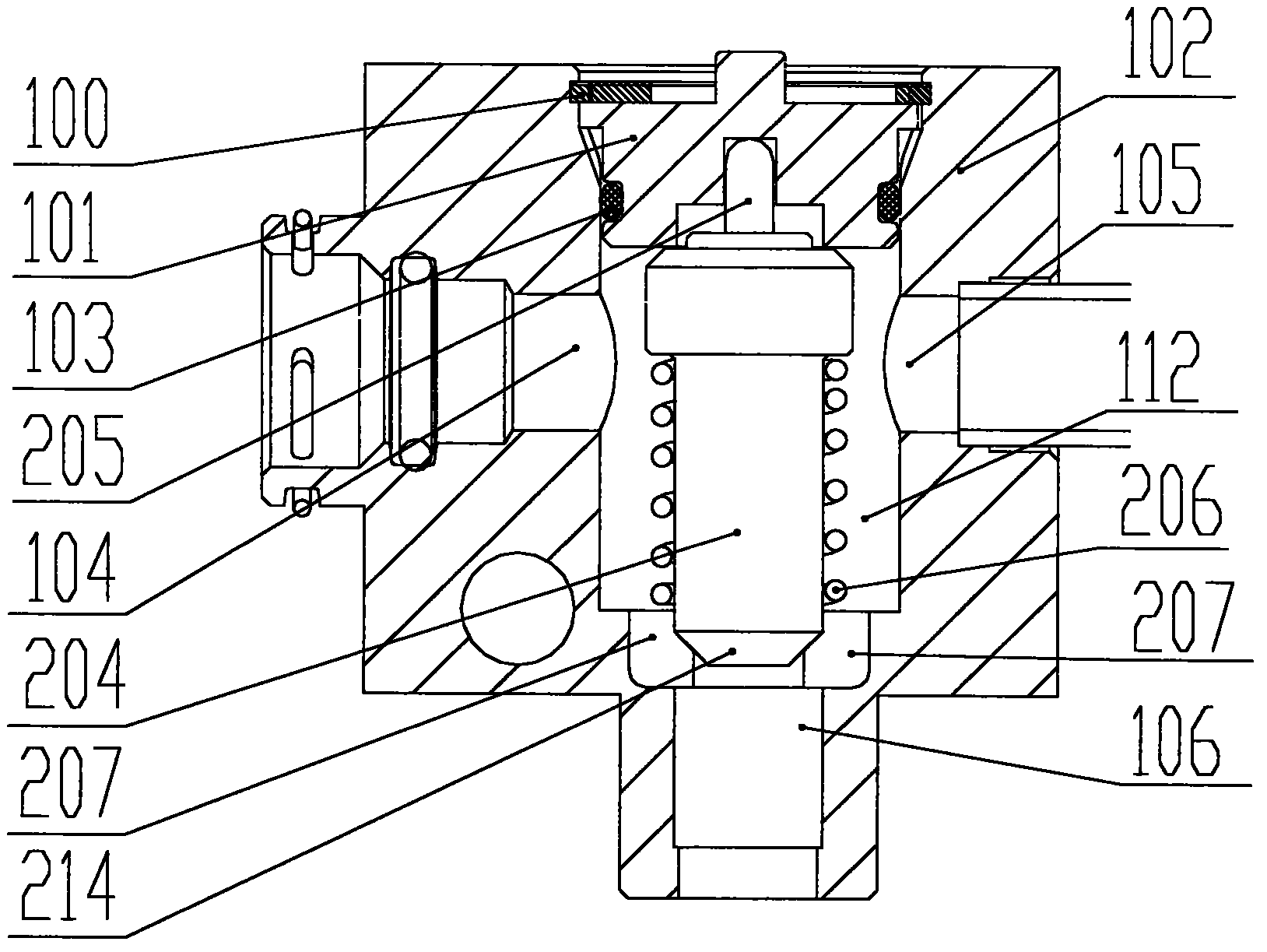

[0033] Such as Figure 1 to Figure 3 The embodiment of the thermostat shown: the thermostat includes a valve body 102 with a cavity 112 and a thermodynamic element fitted in the cavity 112. The thermodynamic element includes a body 204 containing a thermosensitive substance and a sliding installation The ejector rod 205 at the first end of the body 204, one end of the ejector rod 205 is exposed outside the body 204, and the valve body 102 also includes three interfaces respectively communicated with the cavity 112: the first interface 104, the second interface 105 and the third interface 106 , when the thermal element is heated, the heat-sensitive substance e...

Embodiment 2

[0041]The biggest difference between embodiment 2 and embodiment 3 is that the valve body of the thermostat of embodiment 2 is provided with a flow channel communicating with the third interface 106 . However, the third interface 106 of the thermostat valve body in Embodiment 3 needs to be externally connected to pipes connected to other devices. Secondly, the dimensions of the chamfers around the end portion of the second end of the body 204 are also different.

[0042] In the above embodiment, when the thermal element is heated, the thermal element of the thermostat moves toward the third interface 106 and slides in the third interface 106 to block the third interface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com