Automatic assembly equipment for hinge pre-installed tenon and oil injection process

An automatic assembly and tenon technology, applied in metal processing equipment, mechanical equipment, manufacturing tools, etc., can solve the problems of multi-working hours and manpower, unstable pre-assembly quality, and fatigue of workers, so as to improve assembly production efficiency and realize Fully automatic assembly to ensure the effect of assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The process and assembly equipment of the present invention will be described in detail below in conjunction with the accompanying drawings.

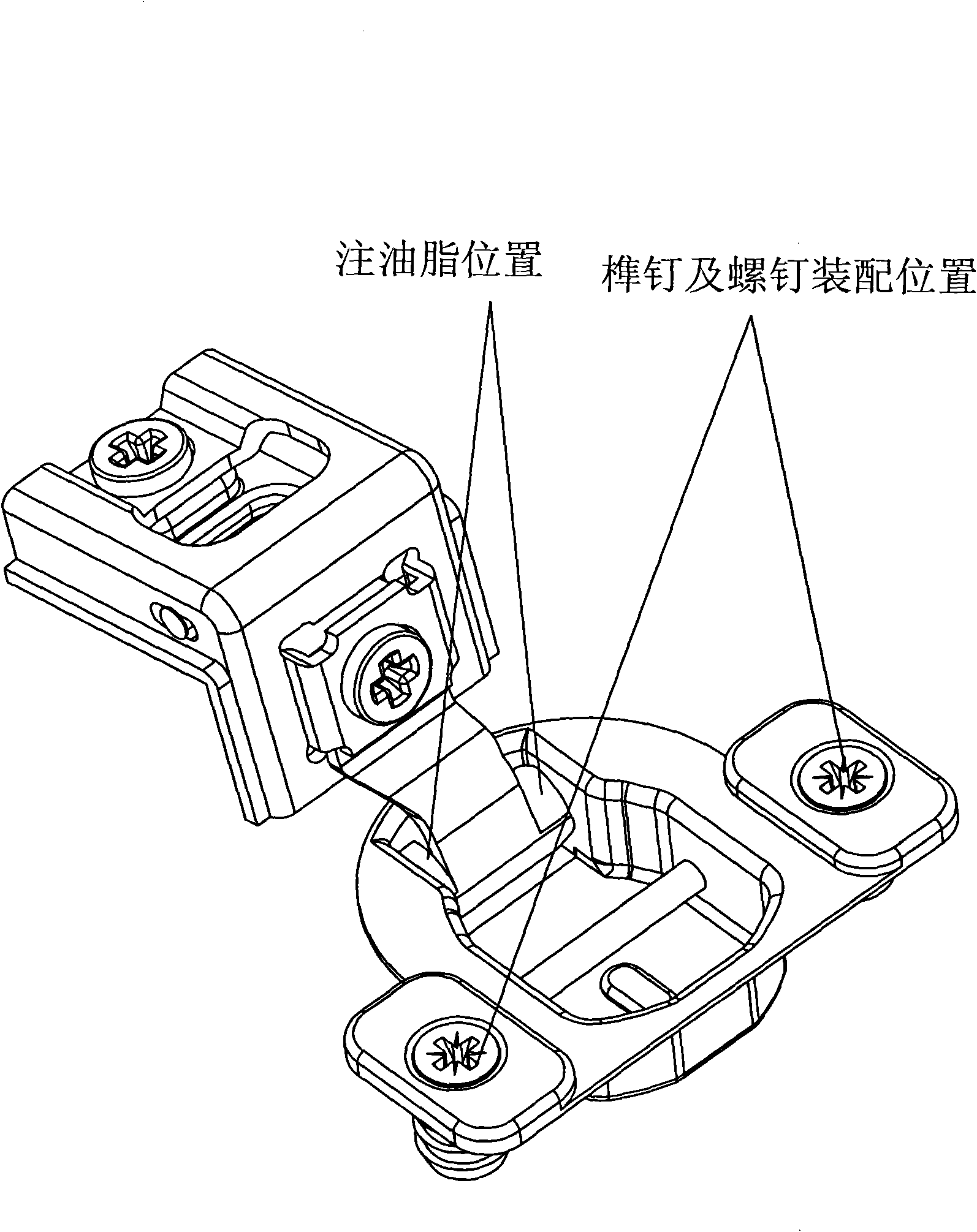

[0030] see figure 1 . There are two positions for pre-installing the mortise and adding grease for the hinge.

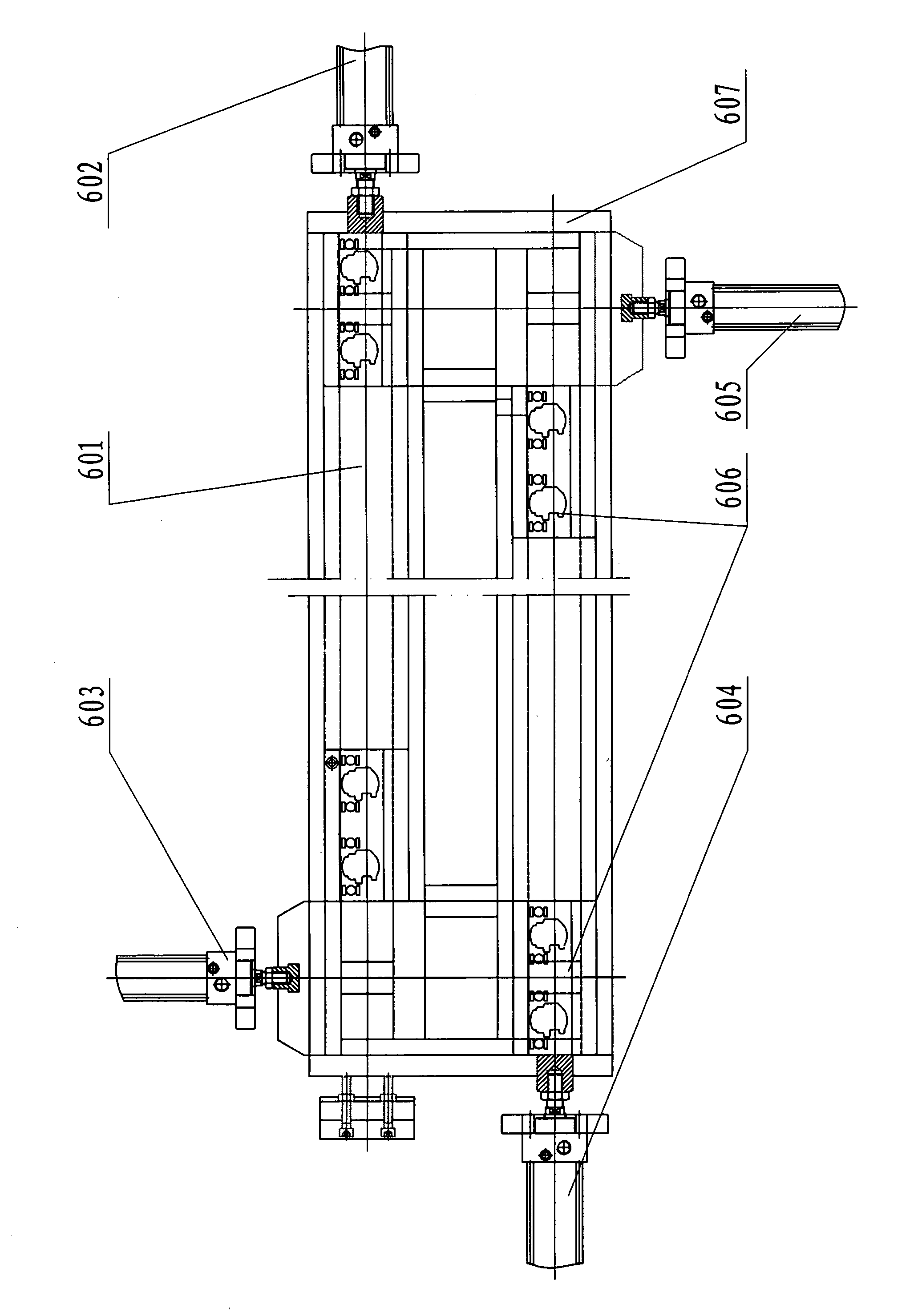

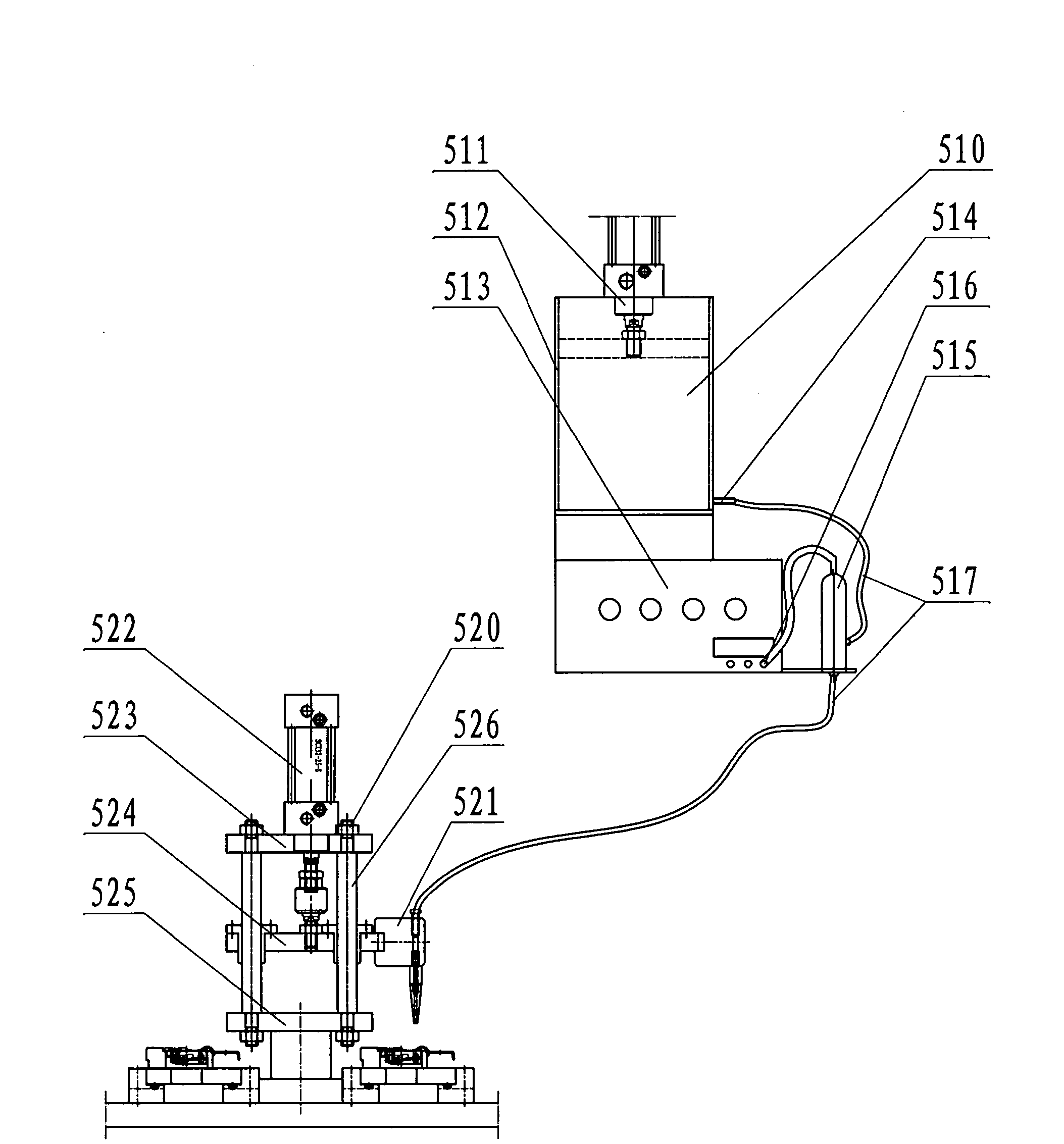

[0031] see figure 2 . The embodiment of the present invention is a double-station automatic assembly equipment, including two sets of tenon grasping mechanism 1, two sets of tenon vibrating feeding mechanism 2, two sets of tenon pre-installation mechanism 3, and two sets of screw vibrating feeding mechanism 4 , a grease injection mechanism 5, a cycle stepping conveying mechanism 6 and a microcomputer control system 7, and the microcomputer control system 7 controls the sequence of actions of the above-mentioned mechanisms.

[0032] see Figure 3 ~ Figure 5 . The guide groove 102 in the tenon grasping mechanism 1 is connected with the piston rod of the cylinder 101, and the cylinder 101 pushes the guide groove 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com