Full-automatic bearing grease feeder

A fully automatic, bearing technology, applied to engine components, engine lubrication, mechanical equipment, etc., can solve problems such as difficult processing, difficult adjustment, difficult maintenance, etc., to achieve the effect of saving complex parts, simple processing and manufacturing, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

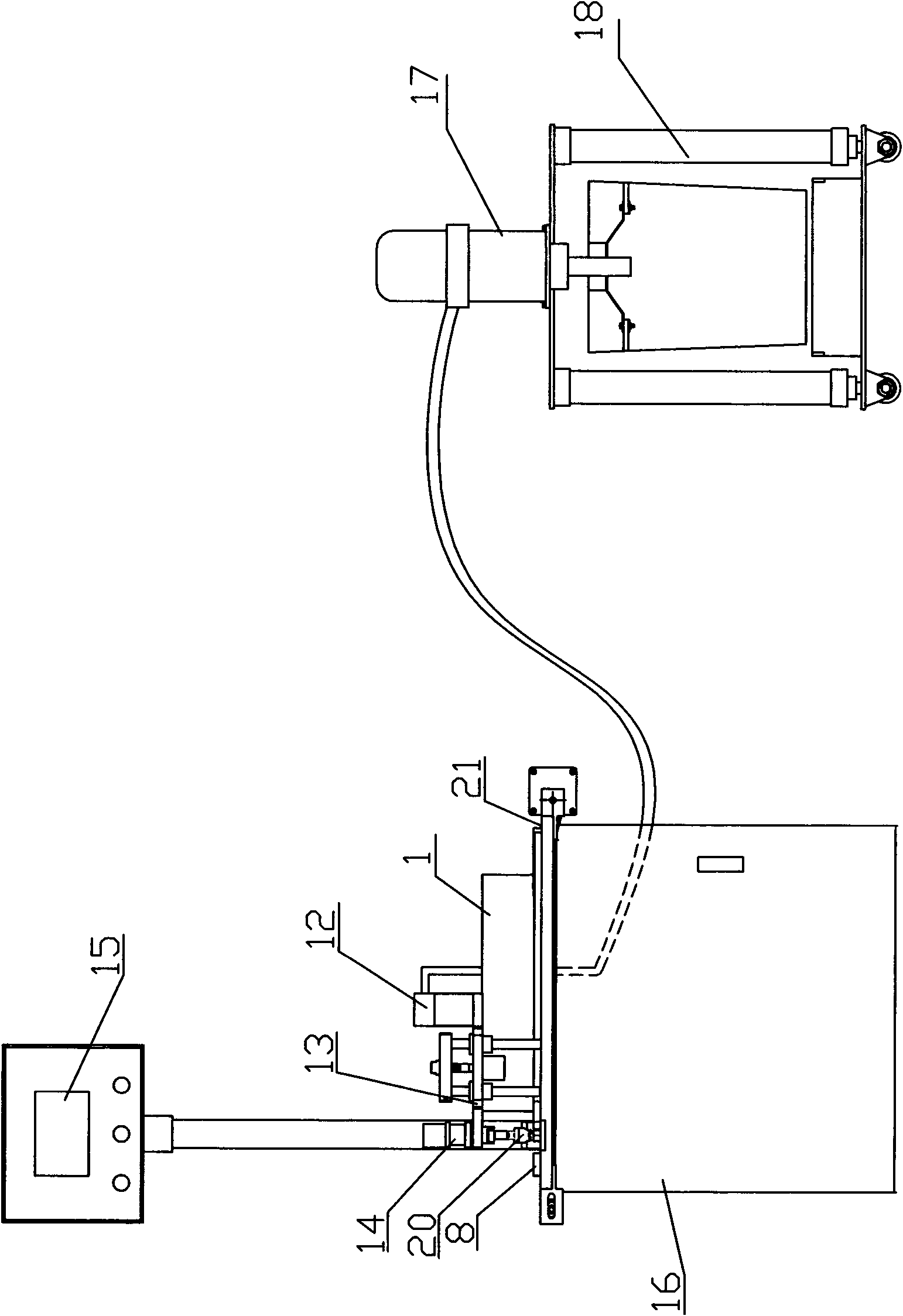

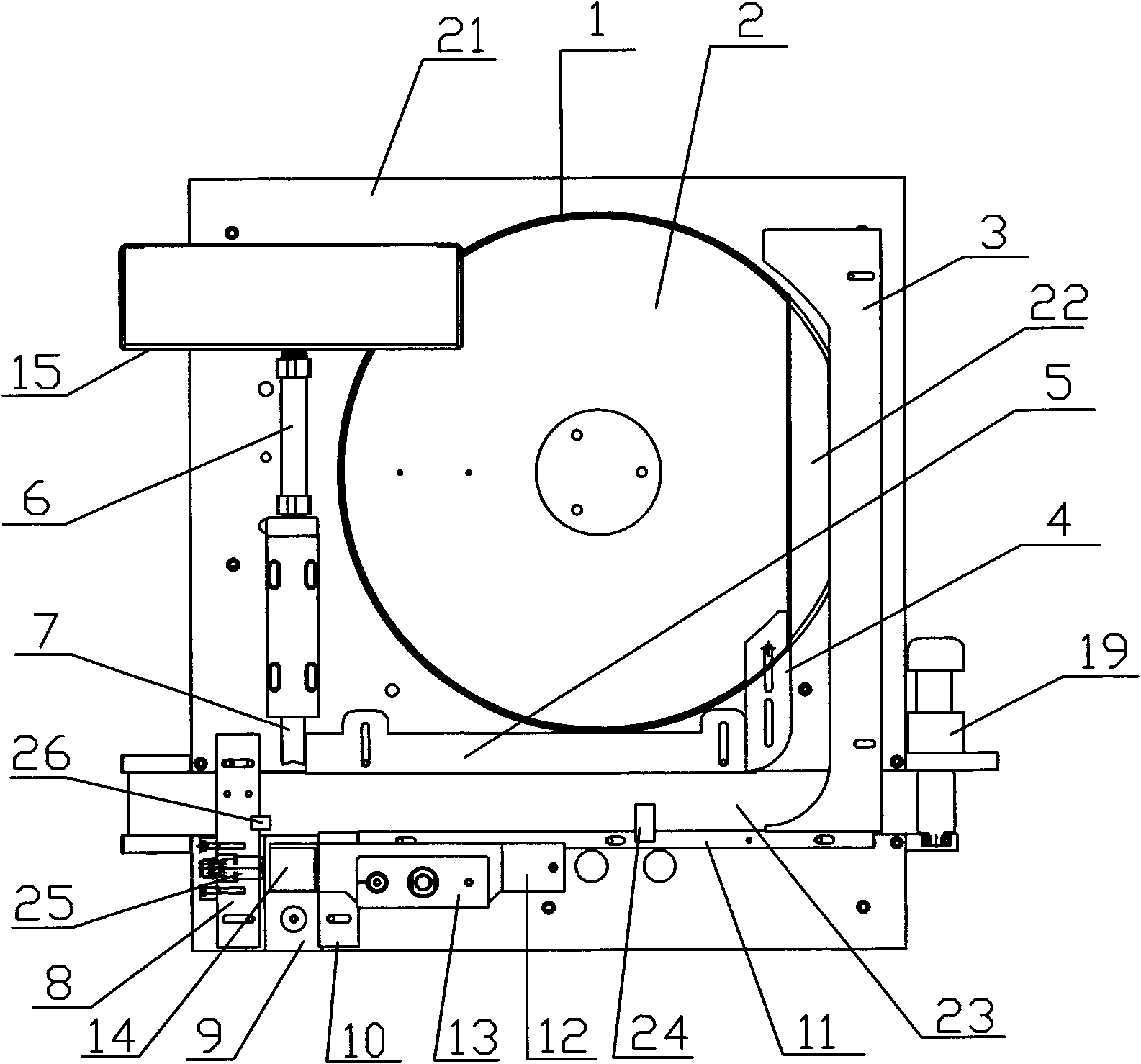

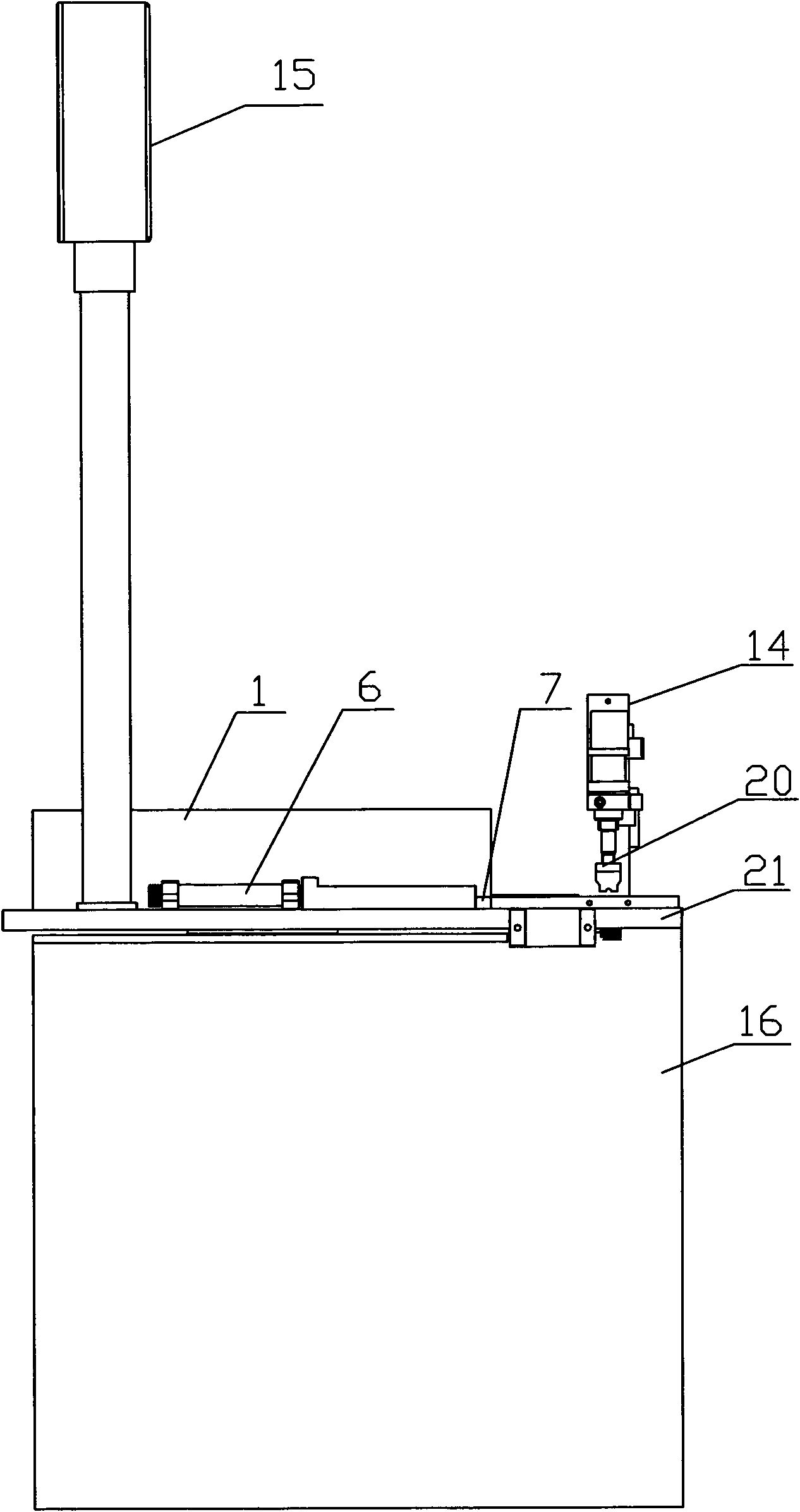

[0017] Refer to the attached figure 1 to attach image 3 The fully automatic bearing greaser of the present invention is described in detail below.

[0018] The structure of the fully automatic bearing greaser of the present invention includes a grease supply device, a workbench 21, a frame 16 arranged below the workbench 21, a greaser device and a disc 1 arranged above the workbench 21, the described The grease supply device is connected with the fat adding device, and the described fat adding device includes a quantitative oil filling valve 12, an oil delivery plate 13 and an oil injector 14, and the described quantitative oil injection valve 12 is connected with the oil injector 14 through the oil delivery plate 13, and the described The lower part of the oil injector 14 is provided with an oil head 20, the disc 1 is provided with a turntable 2, the disc 1 and the workbench 21 are directly welded together, and the disc 1 adopts a cut-out structure , a section is cut off a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com