Minimal quantity lubrication system precise lubrication pump

A technology of micro-lubrication and lubricating pumps, applied in the direction of lubricating pumps, lubricating parts, lubricating oil control valves, etc., can solve the problems of oil cut-off, unsatisfactory lubricating effect, and difficulty in controlling the pump oil volume, and achieve the effect of precise design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

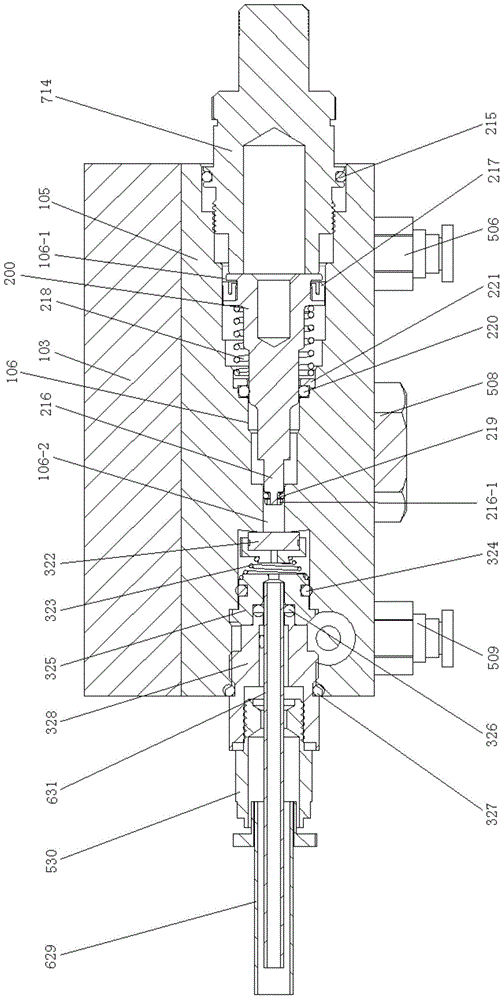

[0096] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

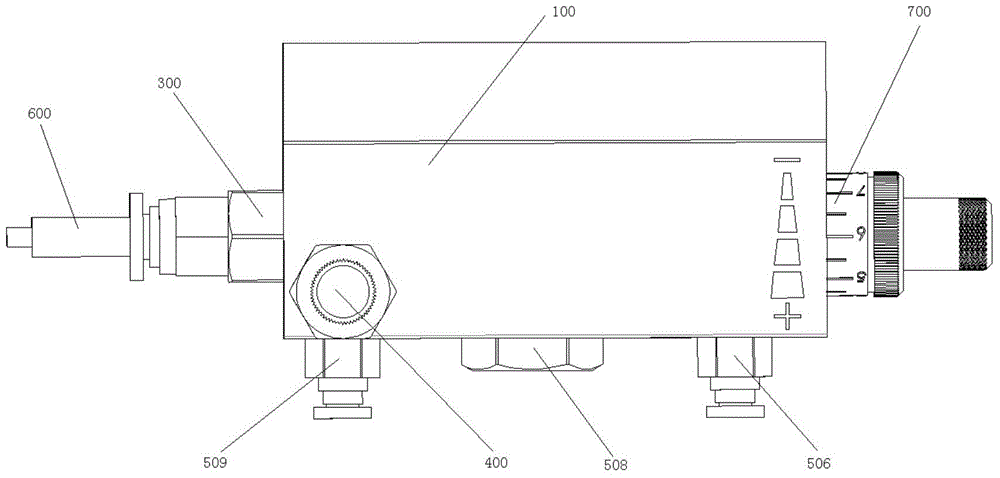

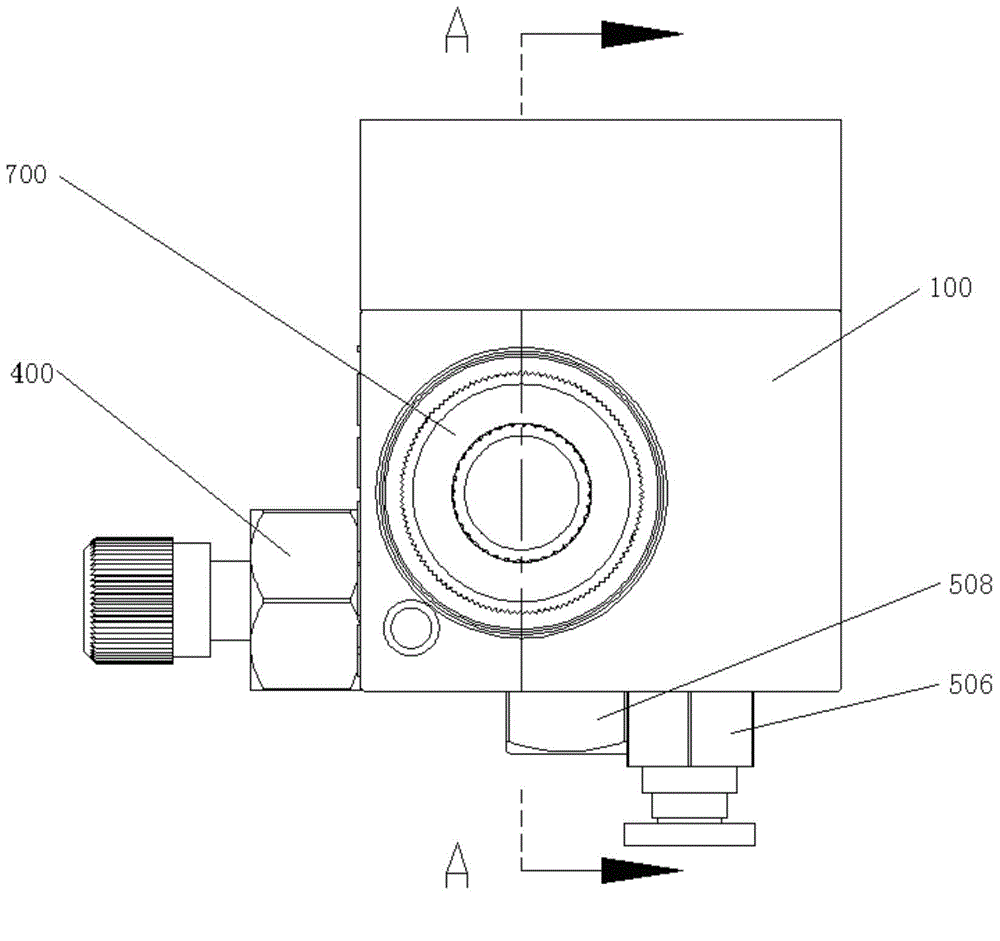

[0097] The precision lubrication pump includes: a pump body unit 100 , an oil volume adjustment unit 700 , a piston unit 200 , a one-way valve unit 300 , a compressed air flow adjustment unit 400 , and a liquid-gas concentric pipe unit 600 .

[0098] The pump body unit 100 has a pump body 105 , the pump body 105 has an inner chamber 106 and an oil inlet hole 102 , and the inner chamber 106 communicates with the oil inlet hole 102 . The pump body 105 also has an air volume regulating hole 107 communicating with the inner chamber 106 close to the one-way valve unit 300 .

[0099] The pump body unit 100 also includes a fixed plate 103 installed on the upper end of the pump body 105. The fixed plate 103 is fixed on the pump body 105 with a fixture. The fixed plate 103 has a hole matching the oil inlet of the pump body 105.

[0100] The fixing part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com