Device and method for moving buoyancy tank of semi-submersible ship

A technology for mobile devices and semi-submersible ships, which is applied in the directions of ship safety, transportation and packaging, ships, etc., can solve the problems of increasing the workload of mobile power pump sets, troublesome installation of slide plates and slide rails, and consumption of large amounts of lubricating grease, etc. Achieve the effect of improving crew operation efficiency, reducing welding man-hours, and reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

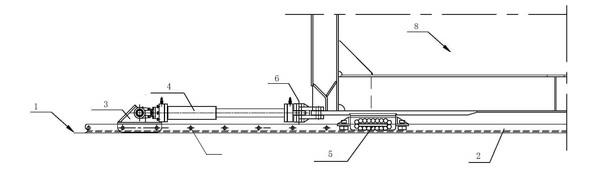

[0021] A kind of semi-submersible floating tank mobile device, such as figure 1 , including two side-by-side parallel guide rails 2 arranged on the deck 1 surface, two guide rails are provided with a plurality of positioning holes 7 in the same position as fixed positions, each guide rail is equipped with a stretching oil cylinder 4, each pull One end of the oil extension cylinder is fixed with a fixed seat 3, which is stuck on the guide rail, and a fixed hole corresponding to the positioning hole is provided at the bottom of the fixed seat, and the fixed seat can be locked on the guide rail by bolts and nuts. It is fixedly connected with the tie plate 6 provided at the bottom of the buoyancy tank, and can be connected with the tie plate through bolts and nuts, or can be directly welded on the tie plate. A plurality of rolling devices 5 are arranged at intervals on each guide rail; the rolling devices can be fixed on the guide rail, and can rotate relative to the guide rail, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com