Lubricator used for reciprocating plunger pump and use method of lubricator

A technology for lubricators and plunger pumps, which is applied to parts of pumping devices for elastic fluids, variable displacement pump parts, pump components, etc., and can solve the problem of high lubrication costs and insufficient lubricating oil for plunger pumps Use and other issues to achieve the effect of improving utilization, reducing lubrication costs, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

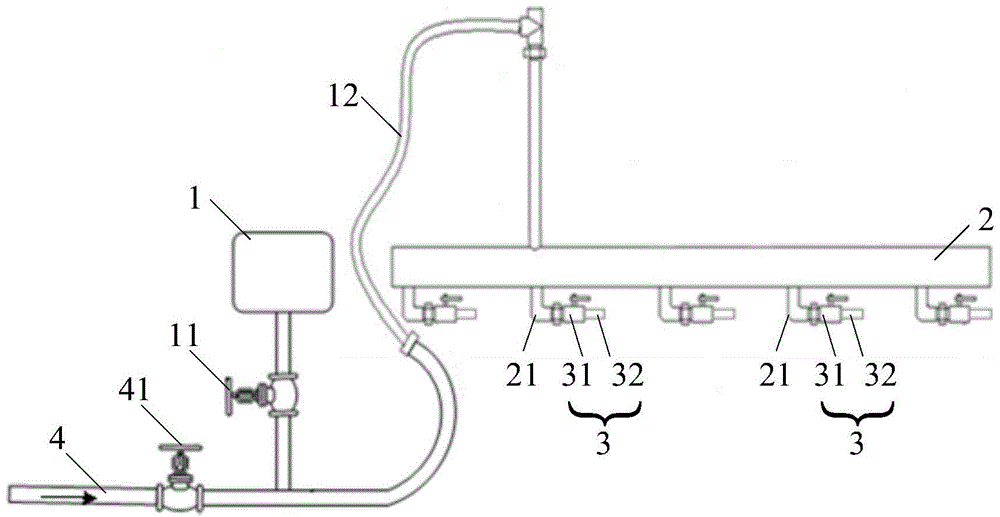

[0032] An embodiment of the present invention provides a lubricator for a reciprocating plunger pump, see figure 1 , the lubricator consists of:

[0033] The lubricating oil tank 1, the lubricating oil control valve 11 installed at the oil outlet of the lubricating oil tank 1, the balance pipe 2 and at least one dripper 3 installed above the plunger of the plunger pump, the dripper 3 includes a diverter regulating valve 31 and The drip nozzle 32, the lubricating oil tank 1 communicates with the balance pipe 2 through the connecting hose 12, and the balance pipe 2 is evenly distributed along its axis direction with at least one elbow 21, and one end of the elbow 21 is connected with one end of the diversion regulating valve 31, and the diversion adjustment The other end of the valve 31 is connected with a drip nozzle 32 .

[0034] The lubricator also includes: an incoming water line 4 connected to a water source and an incoming water control valve 41 installed on the incoming ...

Embodiment 2

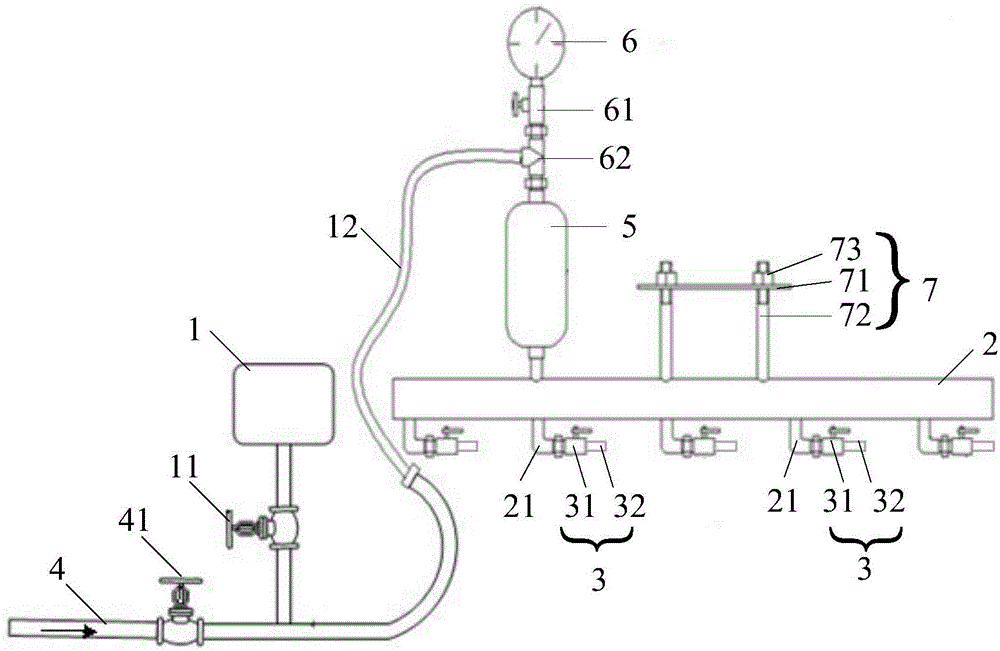

[0042] An embodiment of the present invention provides a lubricator for a reciprocating plunger pump, see figure 2 , the lubricator consists of:

[0043] The lubricating oil tank 1, the lubricating oil control valve 11 installed at the oil outlet of the lubricating oil tank 1, the balance pipe 2 and at least one dripper 3 installed above the plunger of the plunger pump, the dripper 3 includes a diverter regulating valve 31 and The drip nozzle 32, the lubricating oil tank 1 communicates with the balance pipe 2 through the connecting hose 12, and the balance pipe 2 is evenly distributed along its axis direction with at least one elbow 21, and one end of the elbow 21 is connected with one end of the diversion regulating valve 31, and the diversion adjustment The other end of the valve 31 is connected with a drip nozzle 32 .

[0044] The lubricator also includes: an incoming water line 4 connected to a water source and an incoming water control valve 41 installed on the incoming...

Embodiment 3

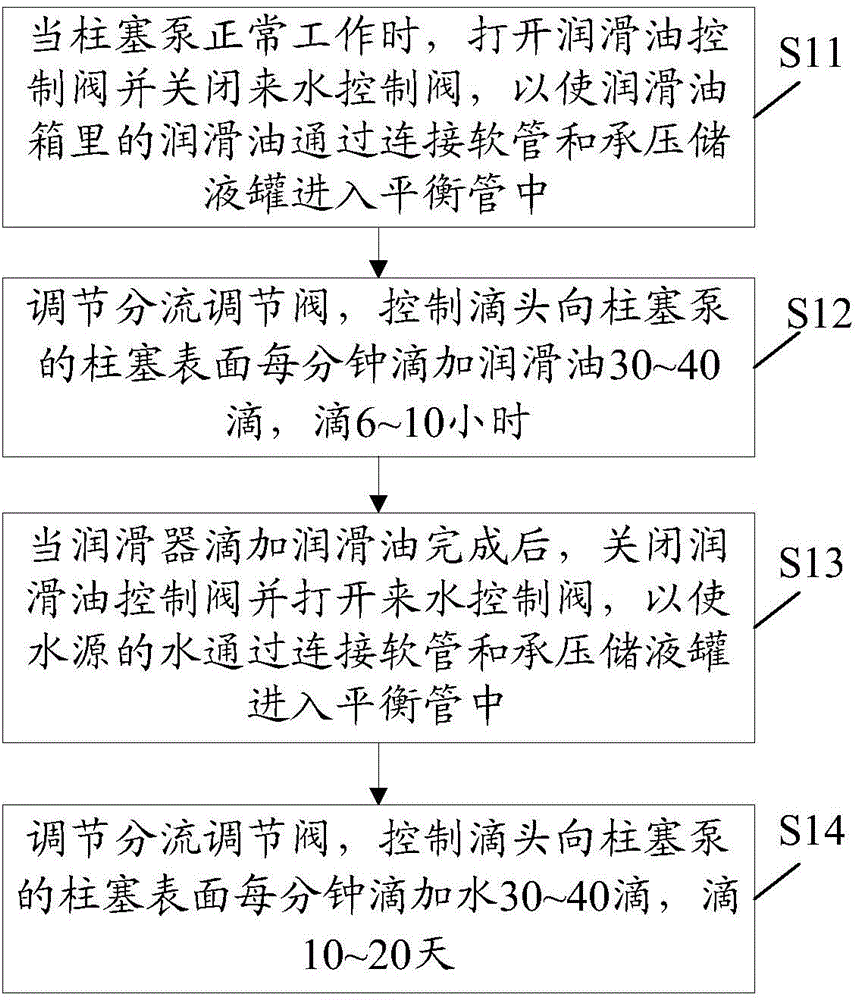

[0068] An embodiment of the present invention provides a method for using a lubricator for a reciprocating plunger pump, see image 3 , the method includes:

[0069] Step S11, when the plunger pump works normally, open the lubricating oil control valve and close the incoming water control valve, so that the lubricating oil in the lubricating oil tank enters the balance pipe through the connecting hose and the pressurized liquid storage tank.

[0070] In practical application, the lubricator needs to be installed first. The specific installation method has been explained above, and will not be repeated here.

[0071] Step S12, adjusting the diverter regulating valve, controlling the dripper to drip 30-40 drops of lubricating oil per minute to the plunger surface of the plunger pump for 6-10 hours.

[0072] In practical applications, the oil dripping speed and the oil dripping time can be adjusted according to the actual situation. For example, in this embodiment, the amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com