Lubricating structure of polishing grinding head

A technology of lubricating structure and grinding disc, which is applied in the direction of grinding head, grinding machine parts, grinding/polishing equipment, etc. It can solve the problems that lubricating oil cannot be discharged to the outside, serious, wear and other problems, so as to avoid high temperature to make lubrication invalid and relatively Less wear and better lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

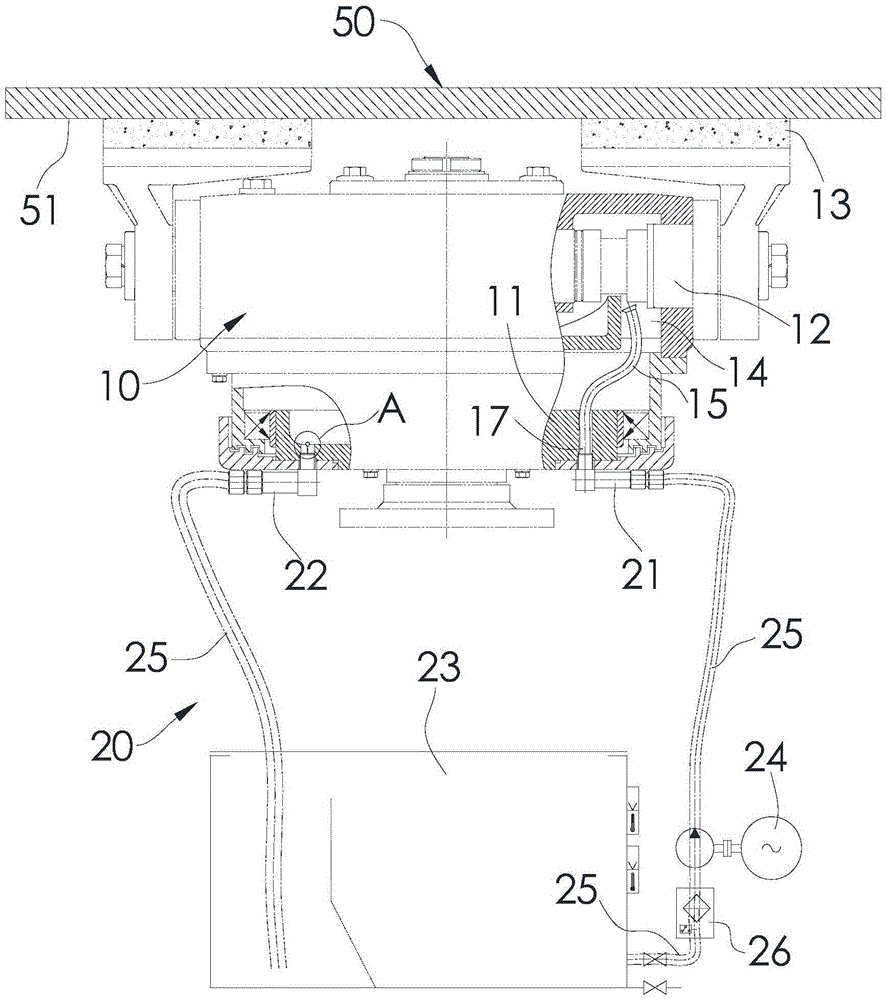

[0022] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

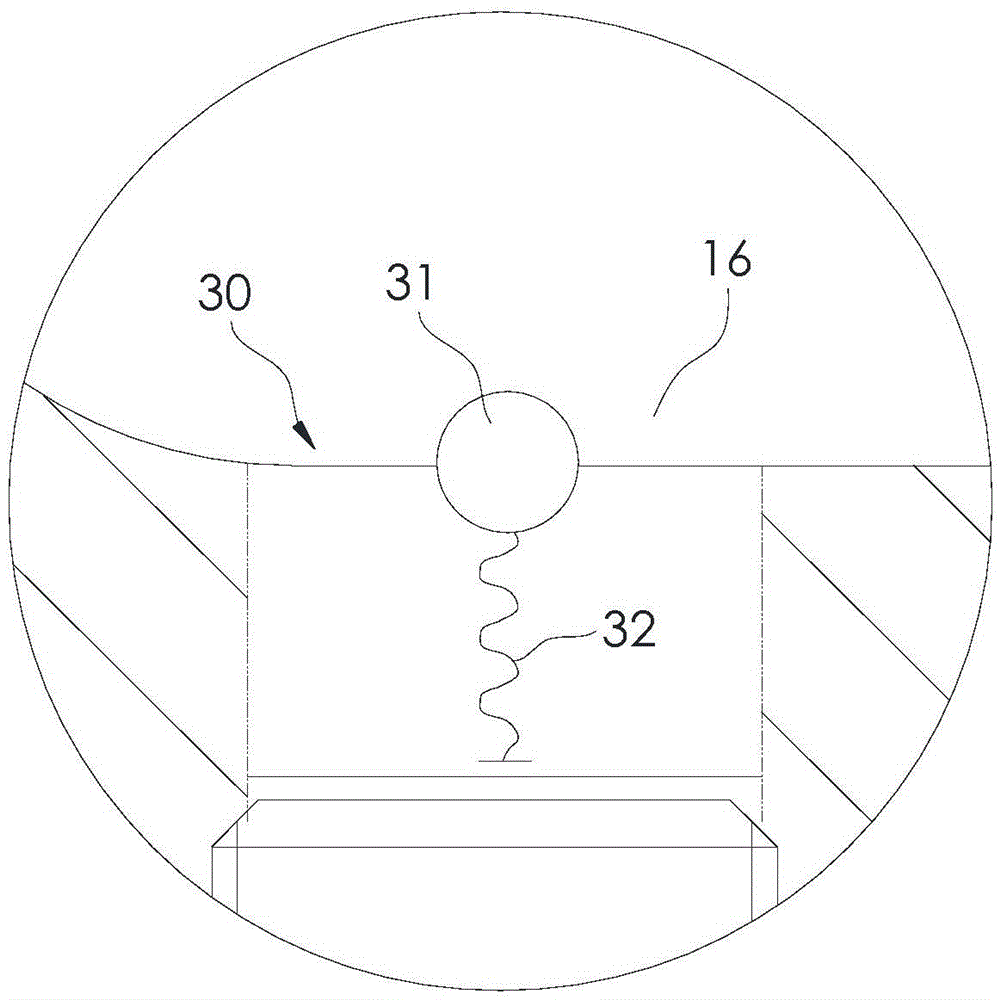

[0023] Such as figure 1 and figure 2 As shown, the lubrication structure of the polishing grinding head of the present invention includes a polishing grinding head 10 and an oil supply circuit 20 . The oil supply circuit 20 includes an oil outlet 21 and an oil return end 22; the polishing grinding head 10 is used to rotate under the driving mechanism and the decorative surface 51 of the ceramic polishing tile 50 from bottom to top (the workpiece of this embodiment is a ceramic polishing tile 50, the decorative surface 51 is the relatively smooth surface of the ceramic polished tile 50, the decorative surface 51 is the surface to be processed of the ceramic polished tile 50), the polishing grinding head 10 includes a mounting seat 11, a grinding disc 12 and a grinding block 13, and the mounting seat 11 is fixed. On the frame of the polishing equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com