Liquid-solid mixed lubricating agent based on graphene strengthening and preparation method thereof

A lubricant and graphene technology, which is applied in lubricating compositions, additives, petroleum industry, etc., can solve the problems of weakened wear resistance and other problems, and achieve the effects of reduced temperature adaptability, simple and easy preparation method, and low corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

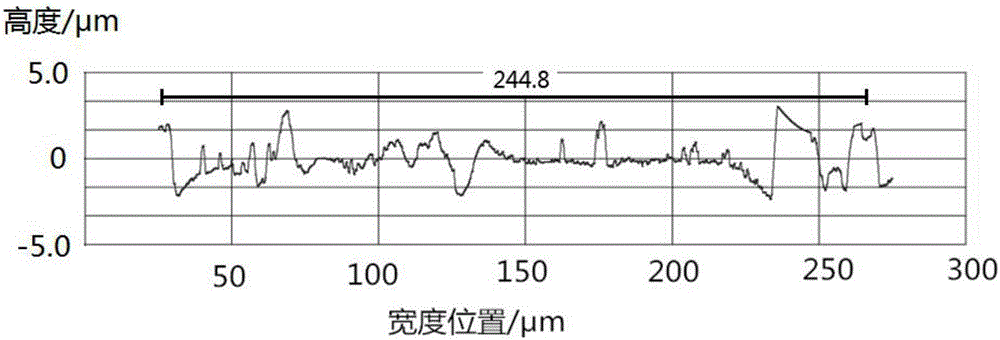

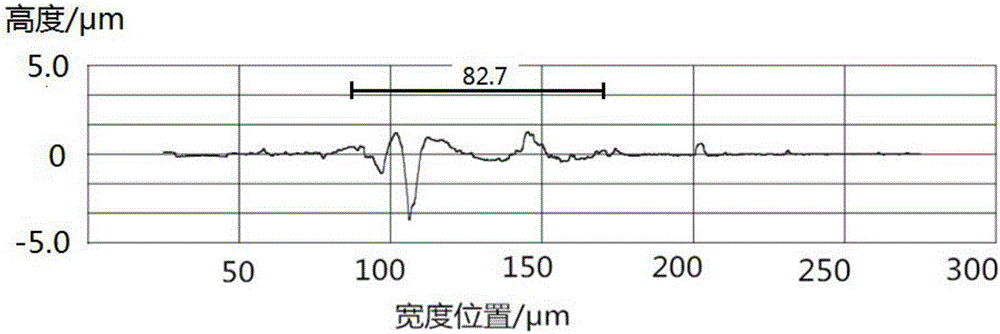

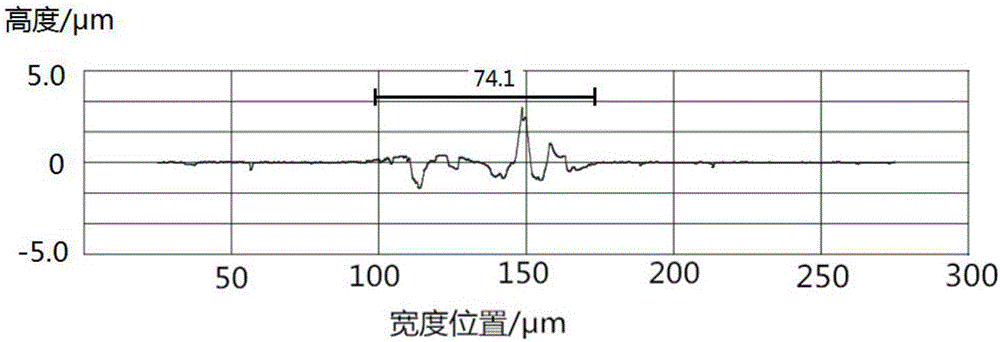

[0027] Such as Figure 1-Figure 4 As shown, the present invention provides a graphene-based liquid-solid hybrid lubricant and a preparation method thereof. The liquid-solid mixed lubricant includes 5.0-10.0% polyphosphate, 0.005-0.015% graphene, 5.0-10.0% sodium dihydrogen phosphate and 80.0-90.0% deionized water, and the polyphosphate is composed of potassium polyphosphate Mixed with sodium polyphosphate at a mass ratio of 2:1, the potassium polyphosphate includes potassium pyrophosphate, potassium tripolyphosphate and potassium metaphosphate, the sodium polyphosphate includes sodium pyrophosphate and sodium tripolyphosphate, the graphite Graphene is added in the solution in the form of graphene water dispersion liquid, wherein the thickness of the graphene sheet fragment of stable dispersion is about 50nm, and the structural molecular formula of described graphene is as follows:

[0028]

[0029] A preparation method based on graphene-enhanced liquid-solid hybrid lubrica...

Embodiment 1

[0034] Embodiment 1 formula sees the following table:

[0035]

[0036]

[0037] According to the weight ratio of the components in the above table: Dissolve 59.95g of sodium dihydrogen phosphate in 790.0g of constant temperature water at 40°C to obtain a primary solution, then mix 30.0g of potassium pyrophosphate and 40.0g of potassium tripolyphosphate at room temperature , 30.0g potassium metaphosphate mixed with 20.0g potassium pyrophosphate and 30.0g sodium tripolyphosphate were uniformly dissolved in the primary solution, stirred for 20 minutes, then the 5ml graphene aqueous dispersion with a concentration of 10mg / ml was added to the solution, and finally The graphene dispersion was subjected to water-bath ultrasonic dispersion treatment for 60 minutes to obtain the graphene-enhanced high-temperature environment-friendly liquid-solid hybrid lubricant of Example 1.

Embodiment 2

[0039] Embodiment 2 formula sees the following table:

[0040] serial number component name Weight (g) 1 potassium tripolyphosphate 100.0 2 sodium tripolyphosphate 30.0 3 Graphene 0.05 4 Sodium dihydrogen phosphate 69.95 5 Deionized water 800.0

[0041] According to the weight ratio of the components in the above table: dissolve 69.95g of sodium dihydrogen phosphate in 800.0g of constant temperature water at 40°C to obtain a primary solution, and then mix 100.0g of potassium tripolyphosphate and 30.0g of tripolyphosphoric acid at room temperature Sodium was mixed and dissolved in the primary solution evenly, stirred for 20 minutes, then 5ml of graphene aqueous dispersion with a concentration of 10 mg / ml was added to the solution, and finally the graphene dispersion was subjected to water-bath ultrasonic dispersion treatment for 60 minutes to obtain Example 2. High-temperature and environmentally friendly liquid-solid hybrid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com