Oil spraying equipment based on closing plate

A technology of closing plates and equipment, applied in the direction of mechanical equipment, engine lubrication, engine components, etc., can solve the problems of insufficient lubrication effect, waste of lubricating oil, complicated oil circuit, etc., to achieve convenient use, simplify oil pipelines, reduce Effects of Lubrication Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] For a better understanding of the present invention, the present invention will be further described below with reference to specific embodiments and accompanying drawings.

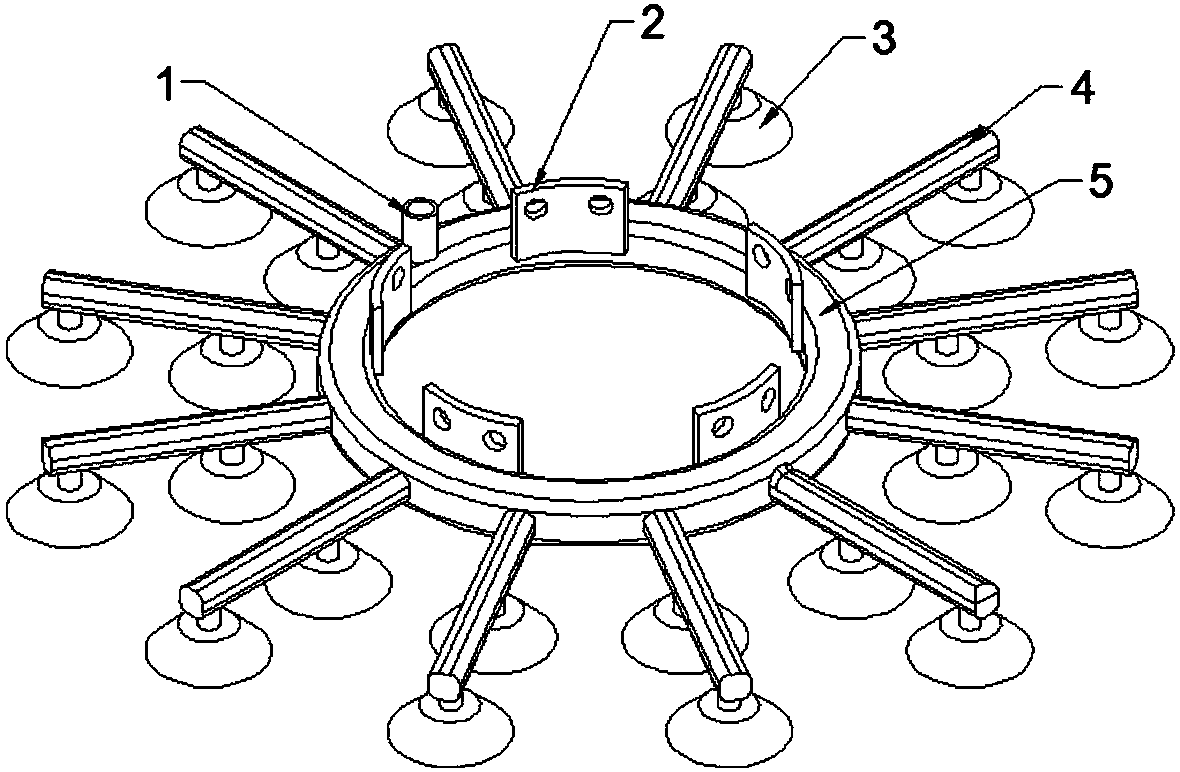

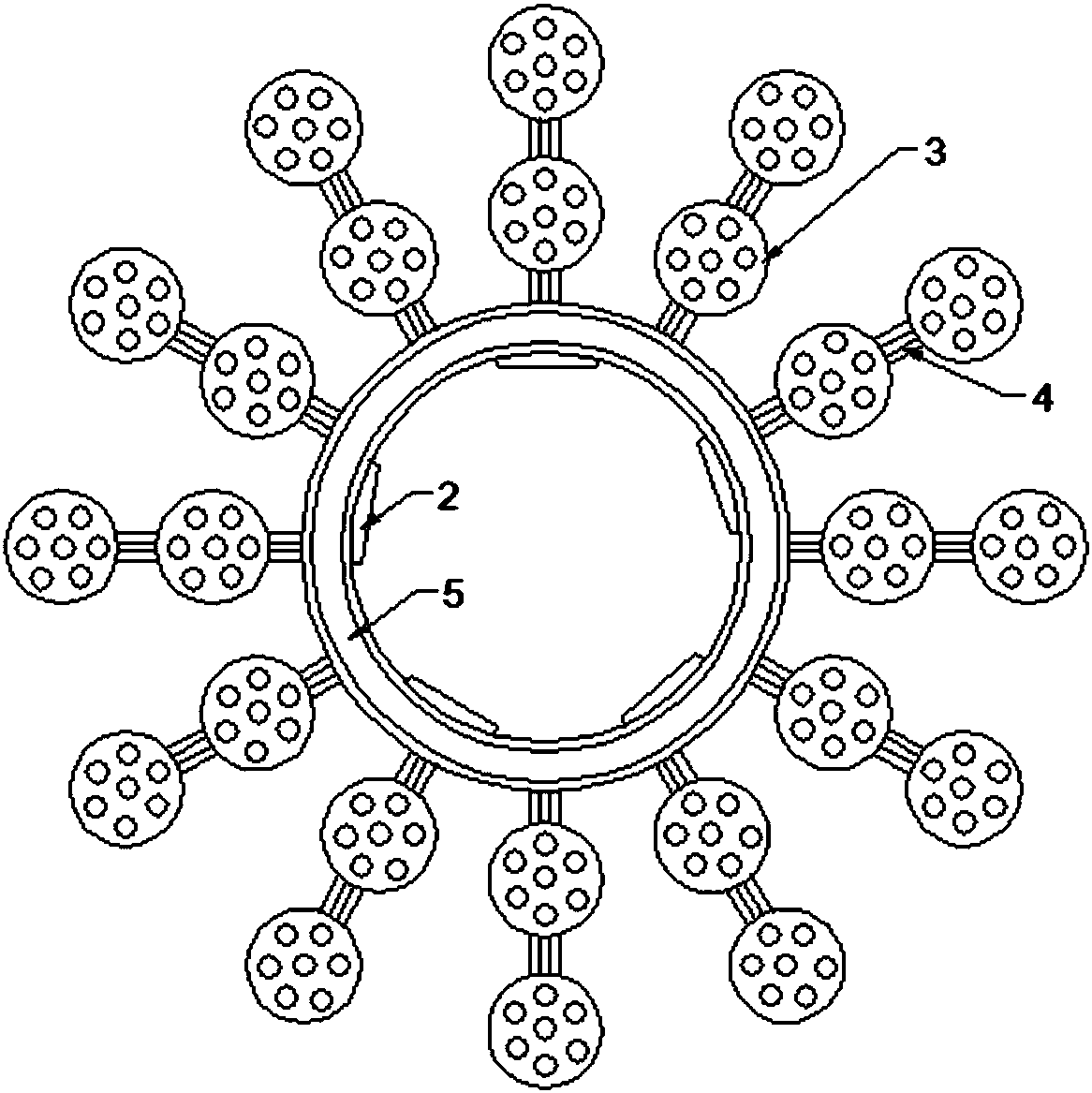

[0016] like Figure 1-2 As shown, an oil injection device based on a closed plate of the present invention includes a closed annular main pipeline 5 and a branch pipe 4 communicated with the main pipeline 5 . The number of the branch pipes 4 is multiple and uniformly distributed around the main pipe 5 in a circular array. The circular array formed by the branch pipes 4 is arranged coaxially with the main pipe 5 , and a plurality of small oil discharge holes are evenly distributed on the branch pipes 4 . The main pipeline 5 is connected with the oil inlet pipe 1 .

[0017] By arranging the annular main pipeline 5, each branch pipe 4 connected to it can be quickly filled with lubricating oil, which simplifies the oil pipeline and makes the use more convenient. By opening a plurality of small oil i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com