Power transmission method and device for engineering machinery

A technology for power transmission devices and construction machinery, which is applied to transmission parts, mechanical equipment, transmission boxes, etc. It can solve problems such as high cleanliness requirements for lubricating oil, impact on the integrity of the transmission system, and space position effects, and achieve low noise , simple structure, and the effect of reducing lubrication costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the examples, but not as a limitation to the present invention.

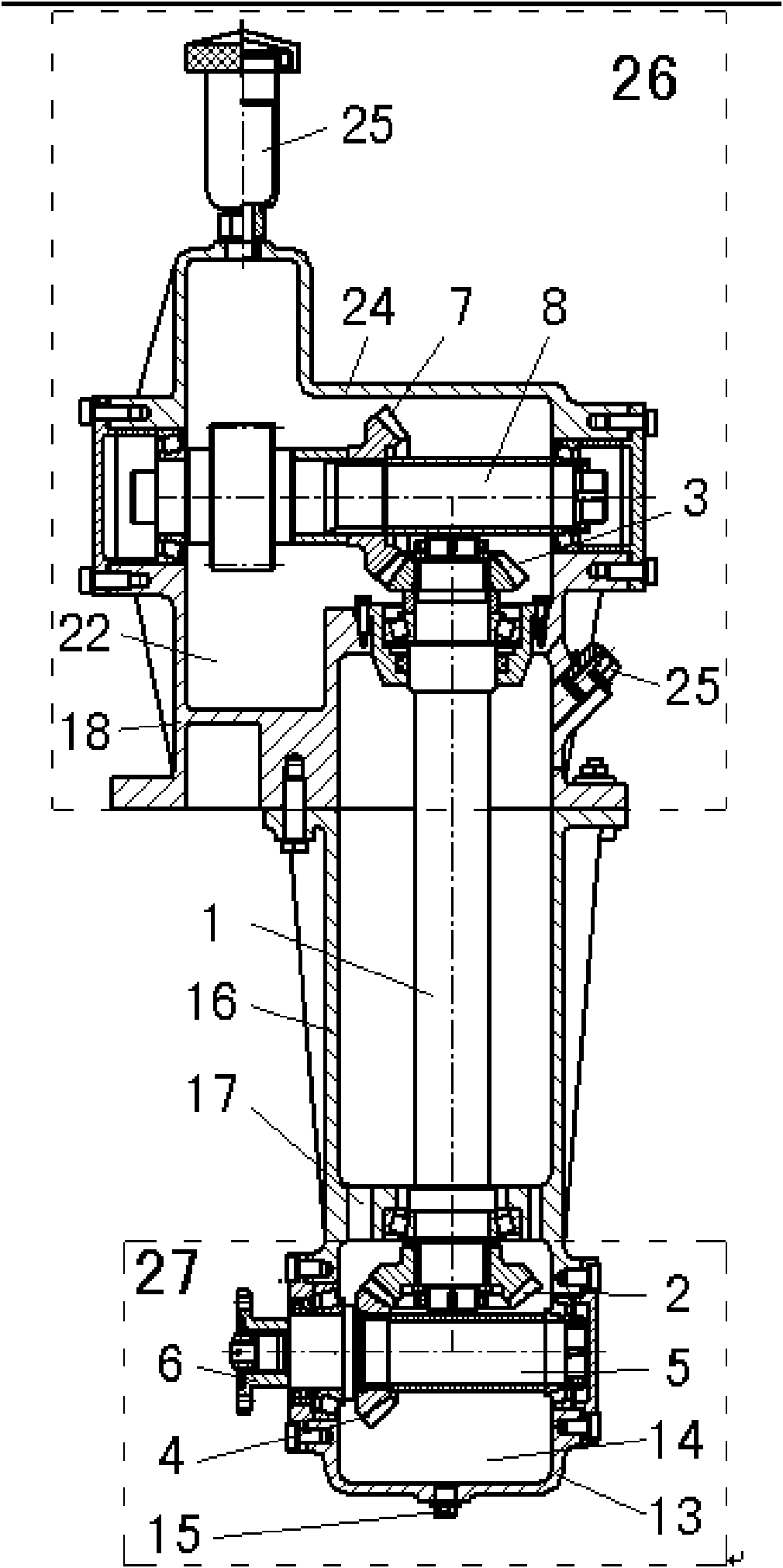

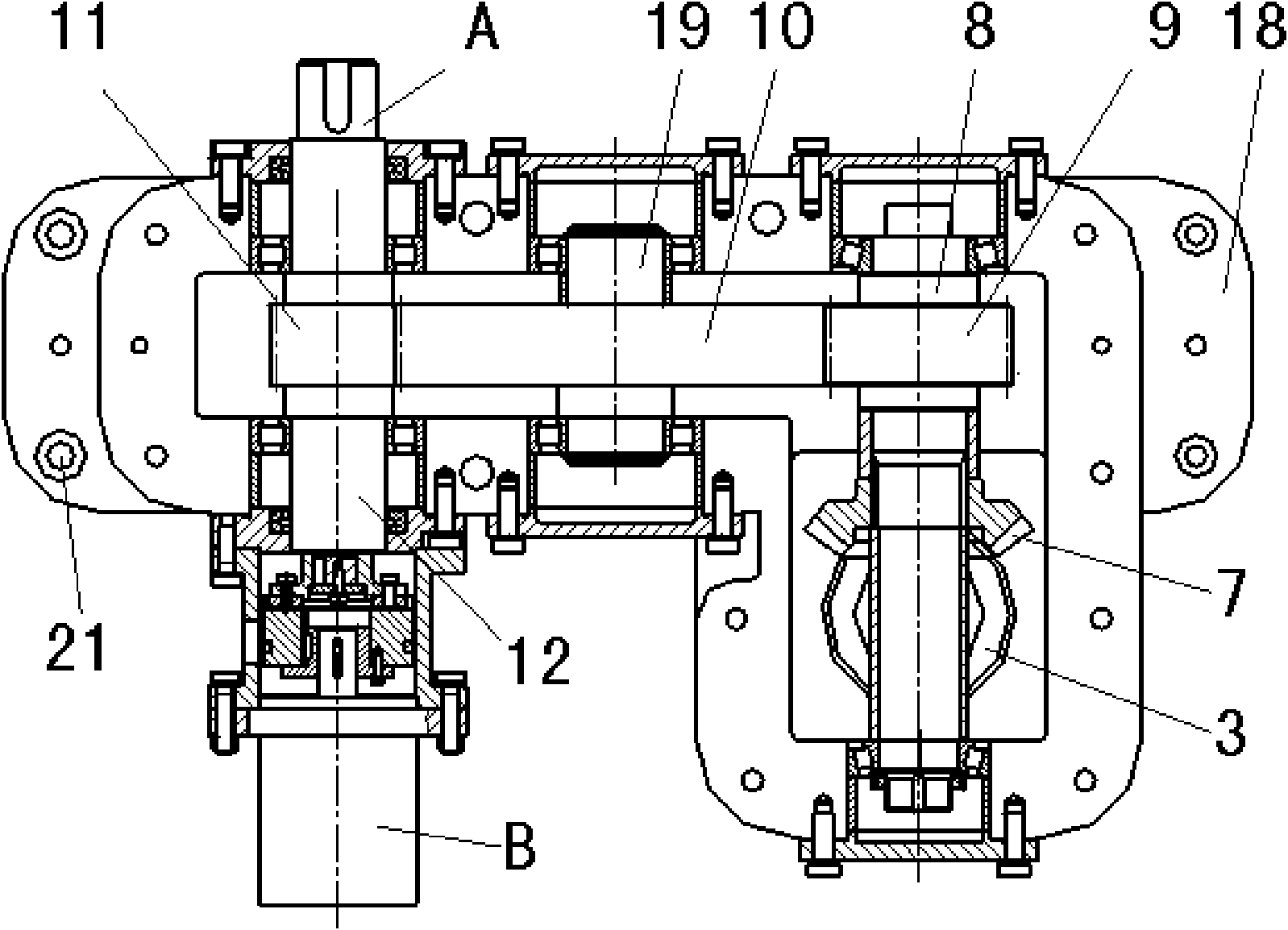

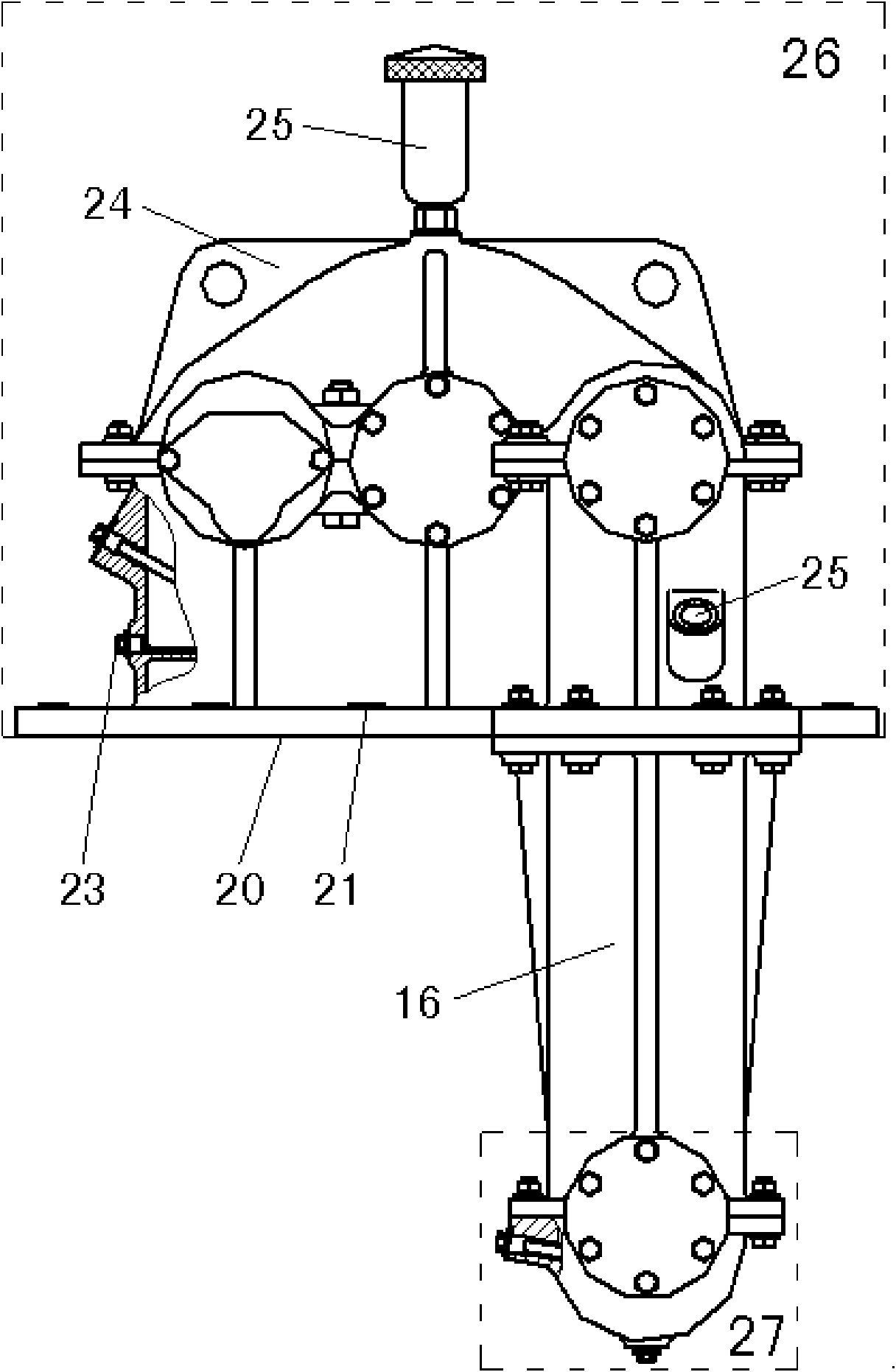

[0021] Embodiments of the invention. A power transmission method for construction machinery, such as figure 1 , figure 2 and image 3 shown. In this method, the input interface provided on the lower casing 13 is connected as a whole with the dual-function interface A and the output interface A arranged on the upper casing 18 through the middle casing 16; The input power is redirected by the pair of bevel gears, and the power is transmitted to the upper casing 18 through the long shaft 1 set in the middle casing 16, and the power from the long shaft 1 is redirected through a pair of bevel gears in the upper casing 18. , and through the driving gear 9, the transition gear 10 and the driven gear 11, the two ends of the driven gear 11 are used as the dual-function interface A and the output interface B respectively. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com